Reaction device, application in synthesizing sodium methyl mercaptide, and synthesis method

A reaction device, sodium hydrosulfide technology, applied in chemical instruments and methods, mercaptan preparation, chemical/physical/physical-chemical reactors, etc., can solve secondary pollution, high equipment and production costs, and increase the complexity of production processes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

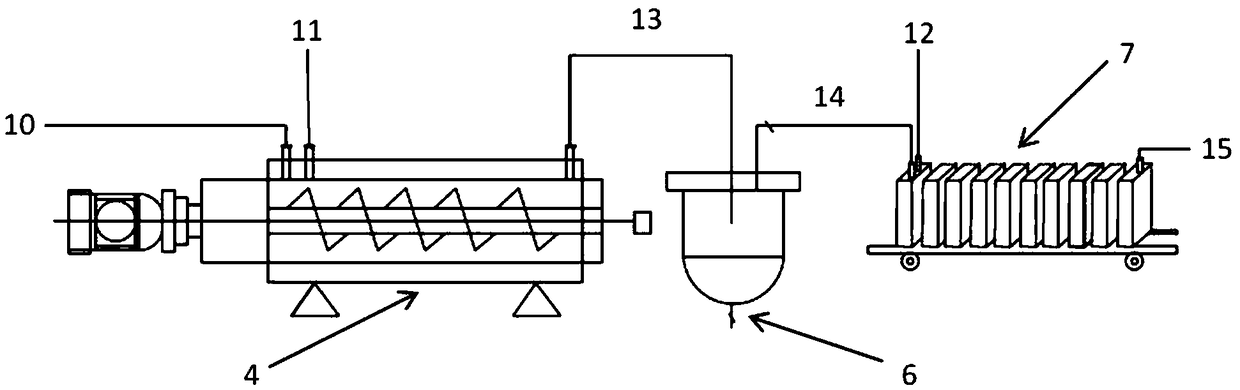

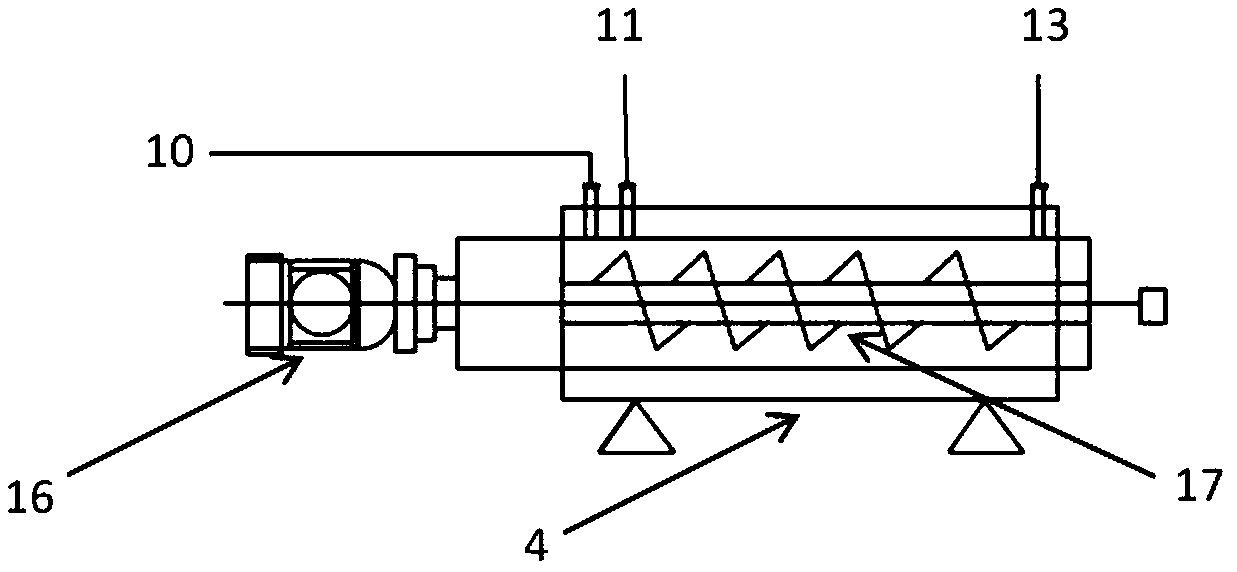

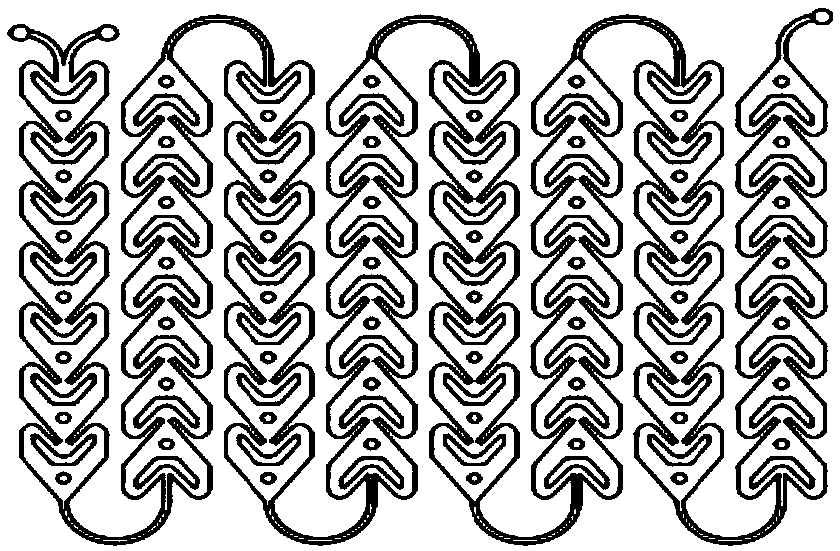

[0107] Connect the two plunger pumps, the tube reactor, and flush with water. Clean the gas-liquid separation tank and connect it to the tubular reactor. Connect the outlet of the gas-liquid separation tank and the outlet of the third pump to the stainless steel microchannel reactor respectively. After the microchannel reactor was rinsed with water, it was filled with 15% NaOH solution.

[0108] The temperature of the tubular reactor was set at 60°C, the feed rate was set so that the molar ratio of sodium hydrosulfide and dimethyl sulfate was 2: 1, and the flow rates of dimethyl sulfate solution and sodium hydrosulfide solution were 9mL / min and 25mL / min, the residence time is 50min. During the reaction process, the temperature is controlled at about 60°C, and the gas-liquid-solid three-phase generated by the reaction enters the gas-liquid separation tank. Methyl mercaptan gas is discharged from the gas outlet of the gas-liquid separation tank into the microchannel reactor, ...

Embodiment 2

[0110] Connect the two plunger pumps, the tube reactor, and flush with water. Clean the gas-liquid separation tank and connect it to the tubular reactor. Connect the outlet of the gas-liquid separation tank and the outlet of the third pump to the stainless steel microchannel reactor. After the microchannel reactor was rinsed with water, it was filled with 15% NaOH solution.

[0111] The temperature of the tubular reactor was set at 65°C, the feed rate was set so that the molar ratio of sodium hydrosulfide to dimethyl sulfate was 2:1.1, and the flow rates of dimethyl sulfate solution and sodium hydrosulfide solution were 10mL / min and 25mL / min, the residence time is 46min. During the reaction process, the temperature is controlled at about 65°C, and the gas-liquid-solid three-phase generated by the reaction enters the gas-liquid separation tank. Methyl mercaptan gas is discharged from the gas outlet of the gas-liquid separation tank into the microchannel reactor, and at the s...

Embodiment 3

[0113] Connect the two plunger pumps, the tube reactor, and flush with water. Clean the gas-liquid separation tank and connect it to the tubular reactor. Connect the outlet of the gas-liquid separation tank and the outlet of the third pump to the stainless steel microchannel reactor. After the microchannel reactor was rinsed with water, it was filled with 15% NaOH solution.

[0114] The temperature of the tubular reactor was set at 65°C, and the feed rate was set so that the molar ratio of sodium hydrosulfide and dimethyl sulfate was 2: 1.2, and the flow rates of dimethyl sulfate solution and sodium hydrosulfide solution were 12mL / min and 28mL / min, the residence time is 43min. During the reaction process, the temperature is controlled at about 65°C, and the gas-liquid-solid three-phase generated by the reaction enters the gas-liquid separation tank. Methyl mercaptan gas is discharged from the gas outlet of the gas-liquid separation tank into the microchannel reactor, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com