Equipment for manufacturing of building materials

A technology for building materials and equipment, which is applied in the direction of separating solids from solids, solids separation, and sieving by air flow, which can solve problems such as waste of resources, and achieve the effect of reducing waste of resources and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

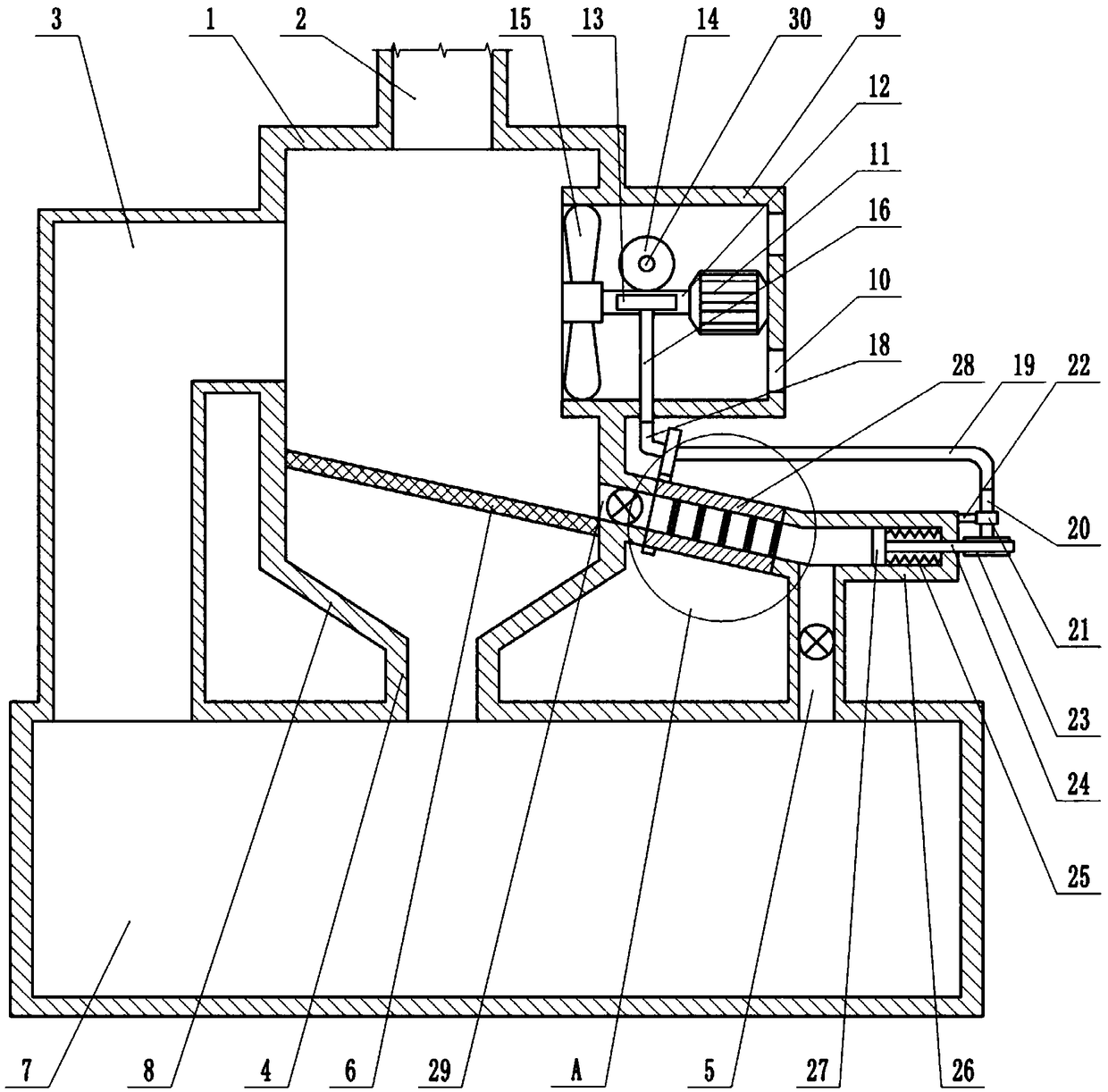

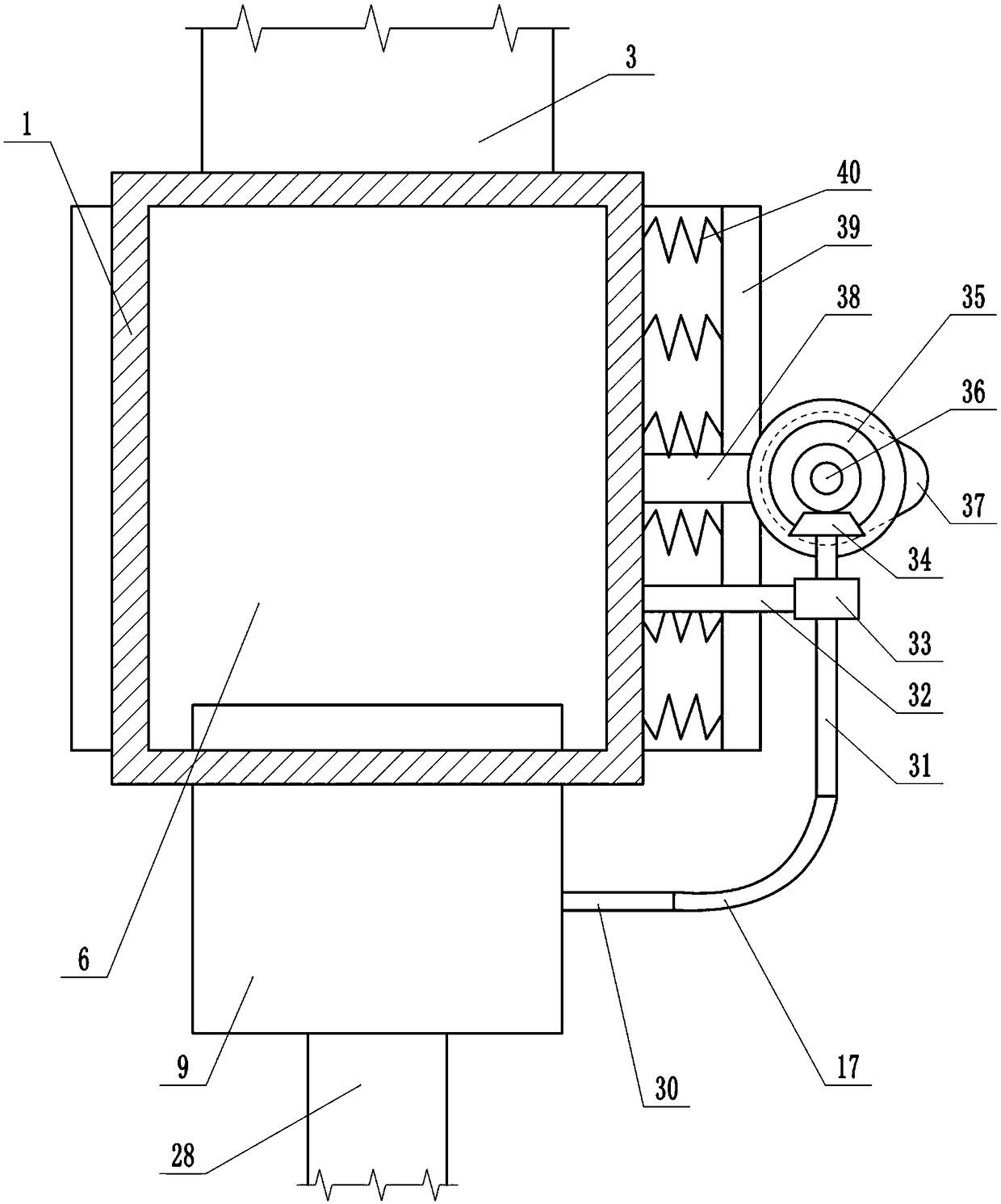

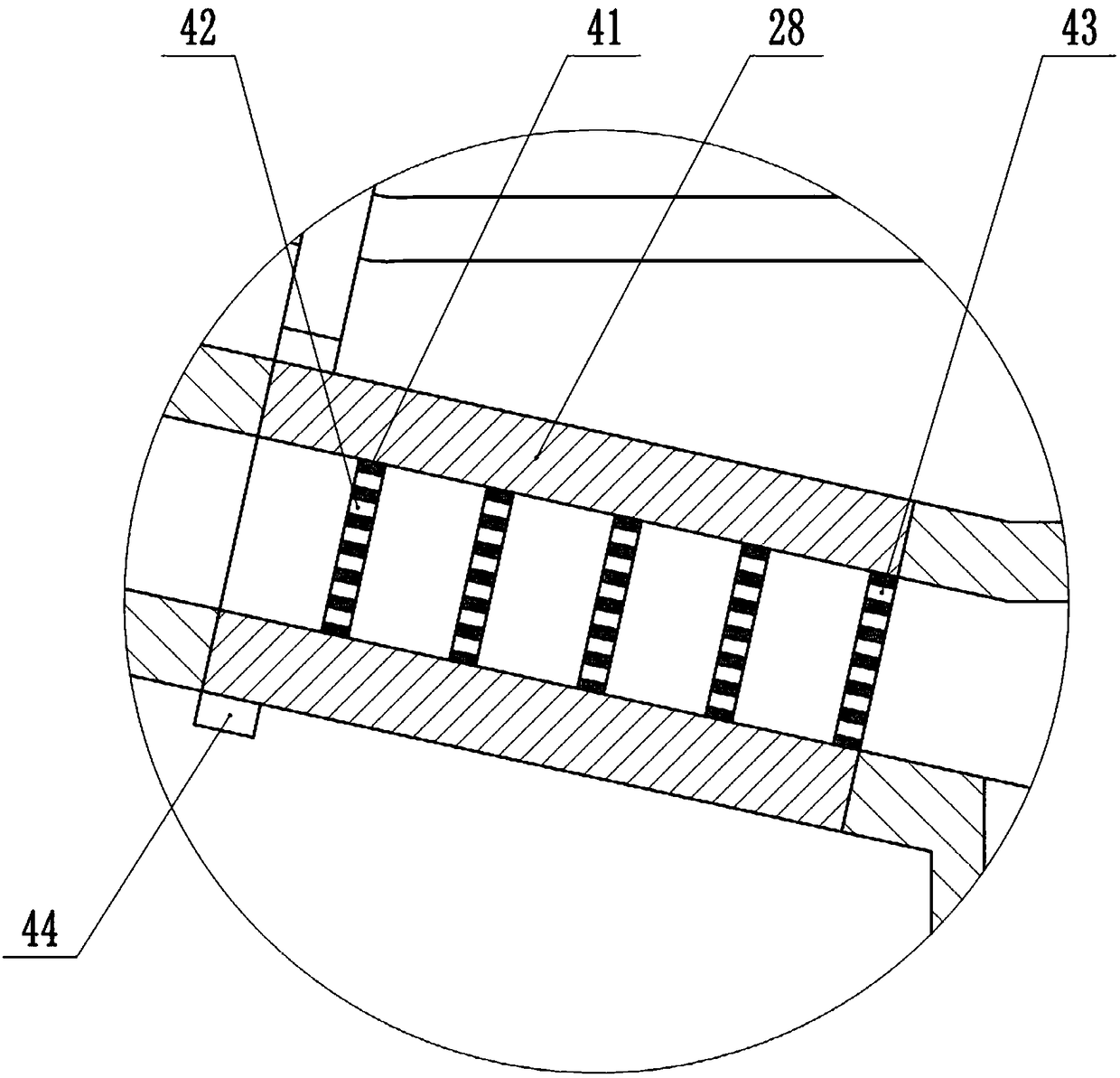

[0015] The reference signs in the drawings of the description include: separation box 1, feed pipe 2, first discharge pipe 3, second discharge pipe 4, third discharge pipe 5, sieve plate 6, collection box 7, hopper 8. Power box 9, air inlet 10, motor 11, motor output shaft 12, first worm gear 13, second worm gear 14, fan blade 15, first drive shaft 16, third flexible shaft 17, second flexible shaft 18, First flexible shaft 19, first transmission shaft 20, first bushing 21, second positioning rod 22, incomplete gear 23, piston rod 24, return tension spring 25, cylinder barrel 26, piston plate 27, thinning tube 28 , discharge port 29, second drive shaft 30, second transmission shaft 31, third positioning rod 32, third sleeve 33, second bevel gear 34, first bevel gear 35, rotating shaft 36, cam 37, first Locating bar 38, pressing plate 39, reset clip spring 40, dividing plate 41, hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com