Multi-mode adjustable automatic card moulding and beautifying machine

An automation certificate and multi-mode technology, applied in the mechanical field, can solve problems such as sawtooth, burrs, and incomplete corners, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

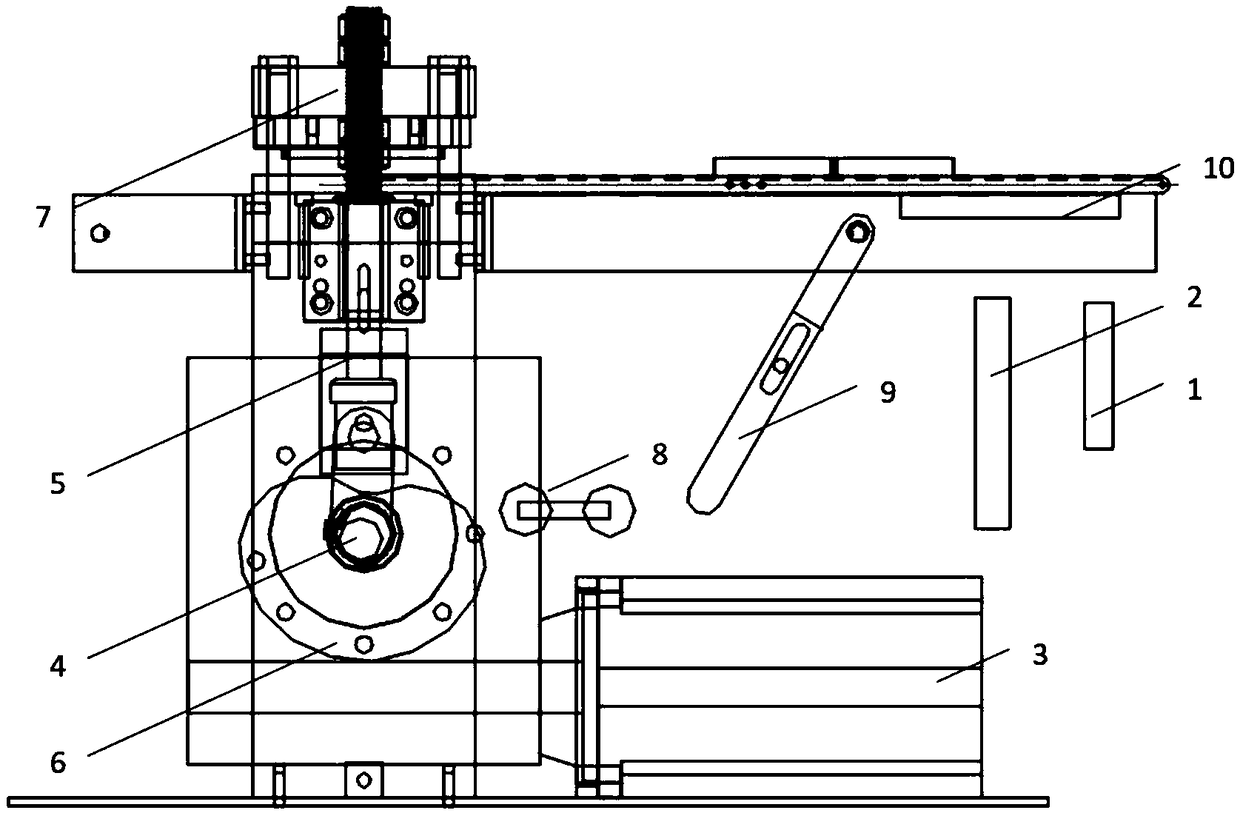

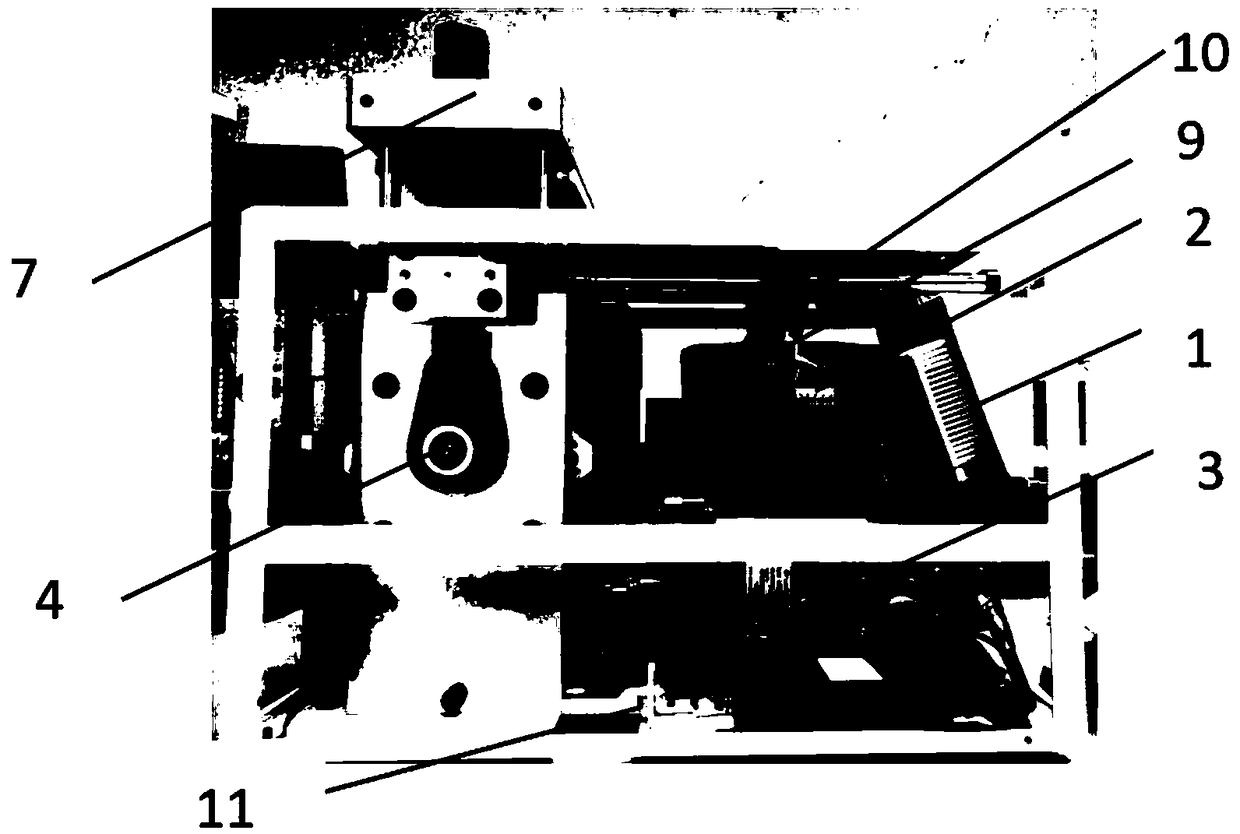

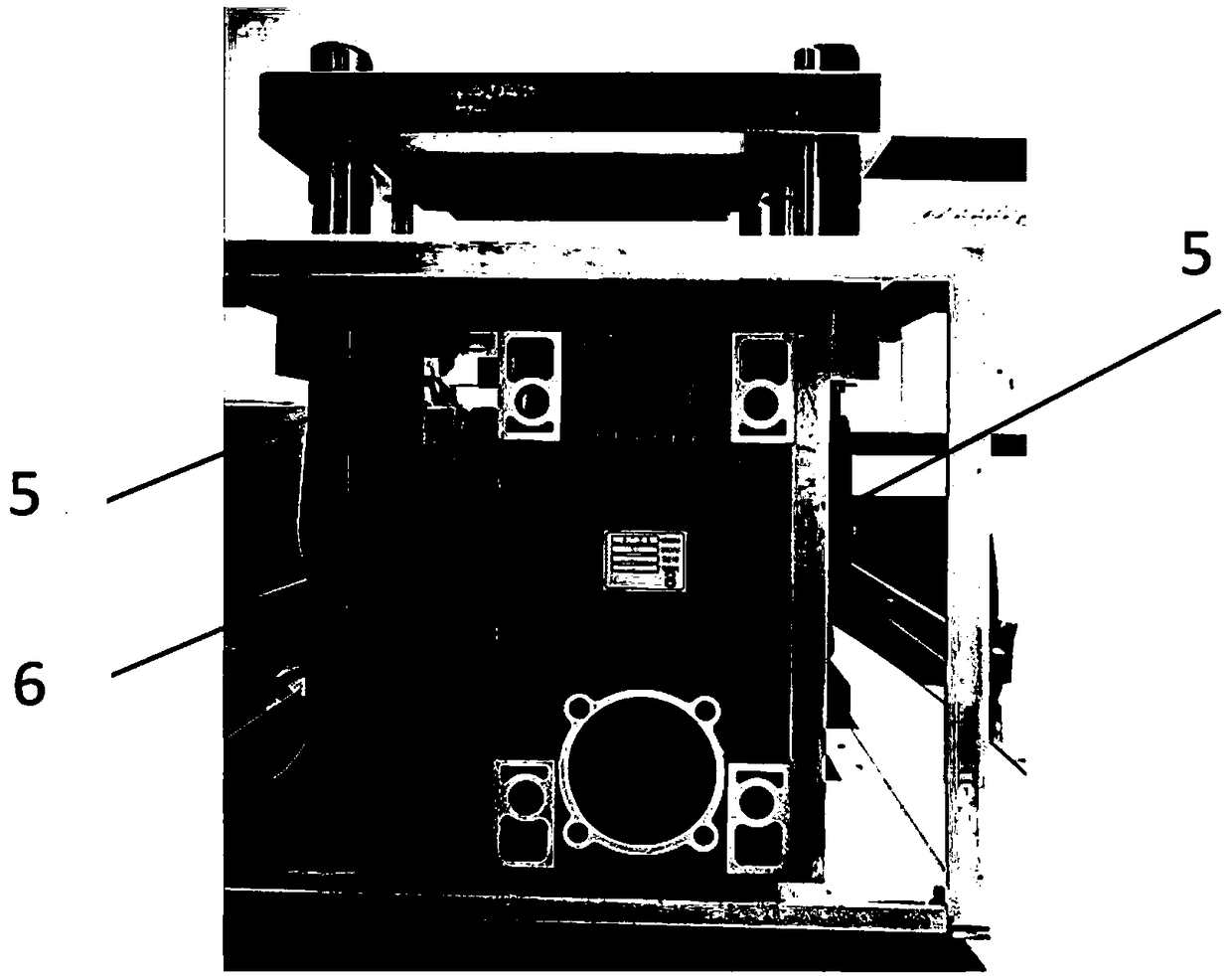

[0017] Specific embodiments of the present invention are described with reference to the above drawings.

[0018] Depend on Figure 1 to Figure 3 It can be seen that the present invention provides a multi-mode adjustable automatic card shaping beauty machine, including a controller 1, an AC server 2, a motor 3, a crankshaft 4, a crankshaft connecting rod 5, a cam 6, a knife mold 7, and a pulley module 8. Connecting rod 9, spring 10, frame 12, the die cutter 7 is arranged on the upper surface of the frame 12, the controller 1 and the AC servo 2 are arranged on one side of the frame 12, the motor 3 is fixed on the frame below the controller 1, the controller 1, the AC servo 2, and the motor 3 are connected to each other, and the crankshaft 4, crankshaft connecting rod 5 and cam 6 are arranged on the knife On the vertical bar of the frame 12 below the mold 7, the die cutter 7, the crankshaft connecting rod 5, the crankshaft 4, and the cam 6 are connected sequentially from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com