White sulphoaluminate cement and production method thereof

A technology of sulphoaluminate cement and its production method, which is applied in the field of cement and can solve problems such as not being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

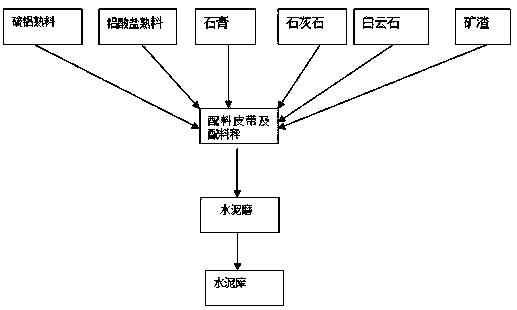

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides a kind of white sulphoaluminate cement, comprises the following components by mass:

[0069] Aluminate clinker: 10%;

[0070] Sulphoaluminate clinker: 40%;

[0071] Gypsum: 15%;

[0072] Limestone: 30%;

[0073] Dolomite: 3%;

[0074] Slag: 2%;

[0075] The whiteness of the aluminate clinker is 91; the whiteness of the sulfoaluminate clinker is 82.

Embodiment 2

[0077] This embodiment provides a kind of white sulphoaluminate cement, comprises the following components by mass:

[0078] Aluminate clinker: 40%;

[0079] Sulphoaluminate clinker: 15%;

[0080] Gypsum: 25%;

[0081] Limestone: 15%;

[0082] Dolomite: 2%;

[0083] Slag: 3%;

[0084] The whiteness of the aluminate clinker is 92; the whiteness of the sulfoaluminate clinker is 87.

Embodiment 3

[0086] This embodiment provides a kind of white sulphoaluminate cement, comprises the following components by mass:

[0087] Aluminate clinker: 55%;

[0088] Sulphoaluminate clinker: 5%;

[0089] Gypsum: 20%;

[0090] Limestone: 15%;

[0091] Dolomite: 1%;

[0092] Slag: 4%;

[0093] The whiteness of the aluminate clinker is 93; the whiteness of the sulfoaluminate clinker is 84.

[0094] Compared with the prior art, the present application replaces the Portland cement clinker in the background technology by aluminate clinker, and can replace the sulfur-aluminum clinker in a larger amount. And this application no longer uses setting retarder, on the contrary, in order to adjust the setting time during actual construction, setting accelerator can be added as appropriate according to needs. Simultaneously the present application has added limestone.

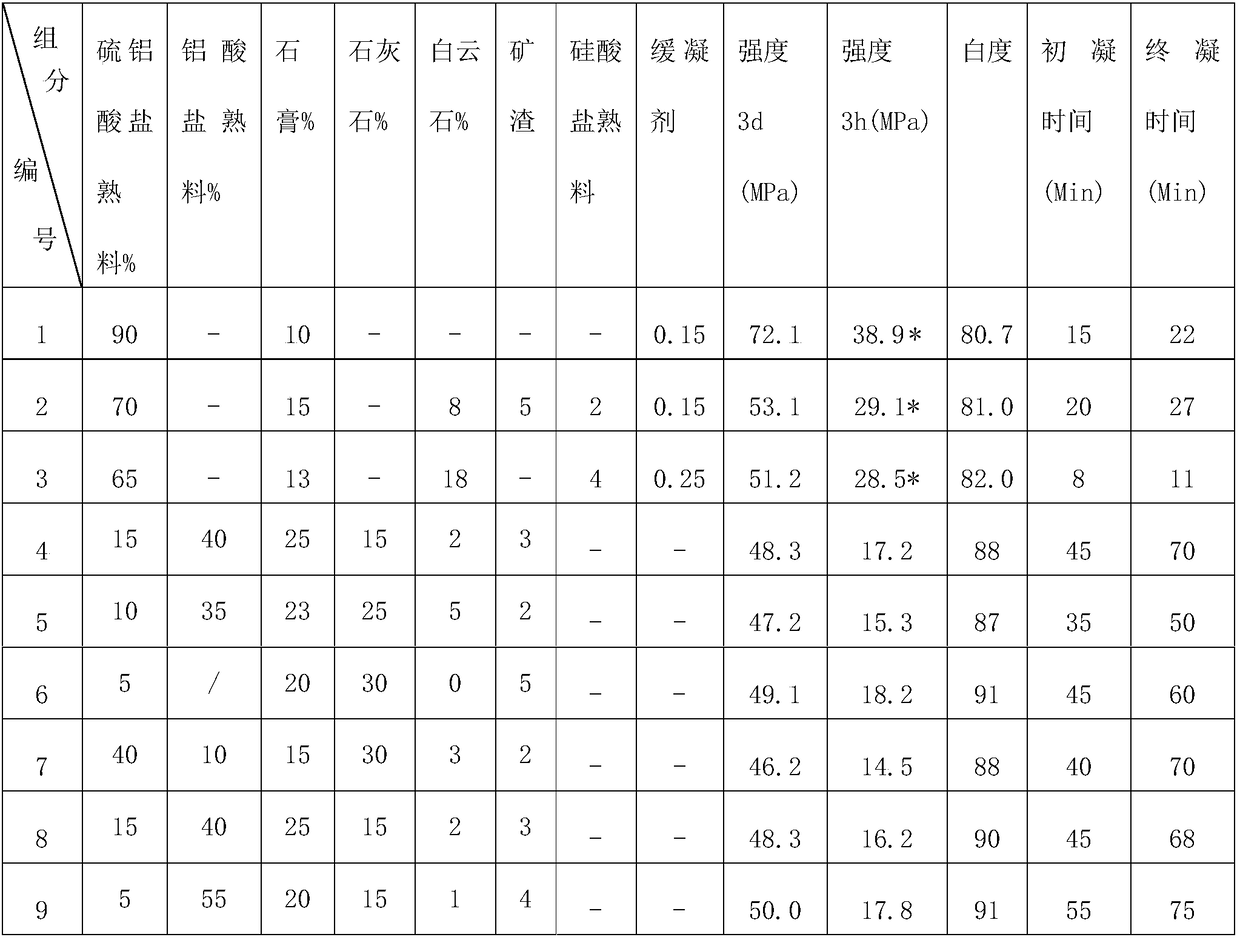

[0095] As shown in Table 1:

[0096] Numbers 1 to 9 in Table 1 represent different white sulphoaluminate cement formulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com