Fluorescence-responsive self-healing hydrogel and preparation method thereof

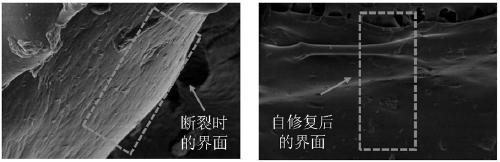

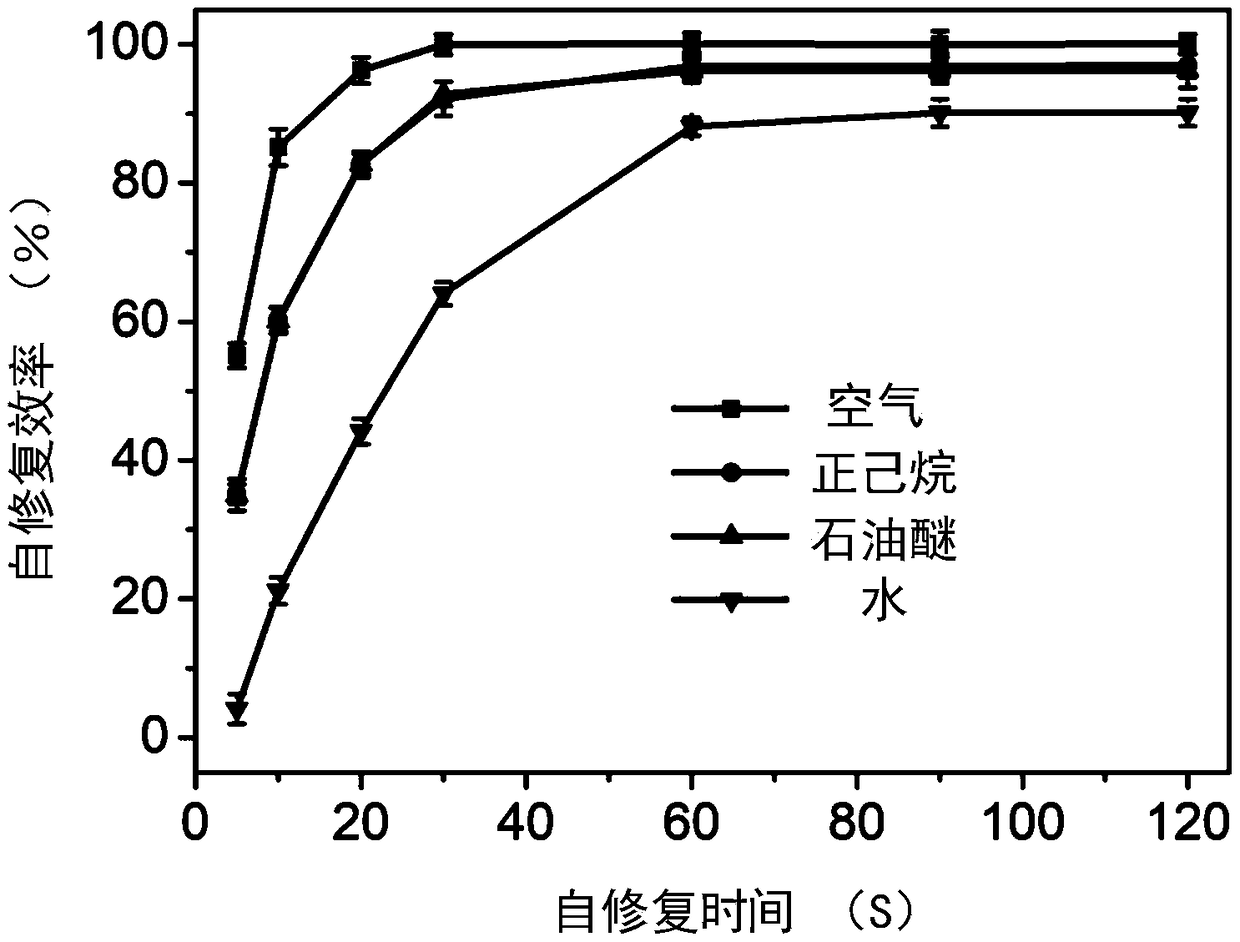

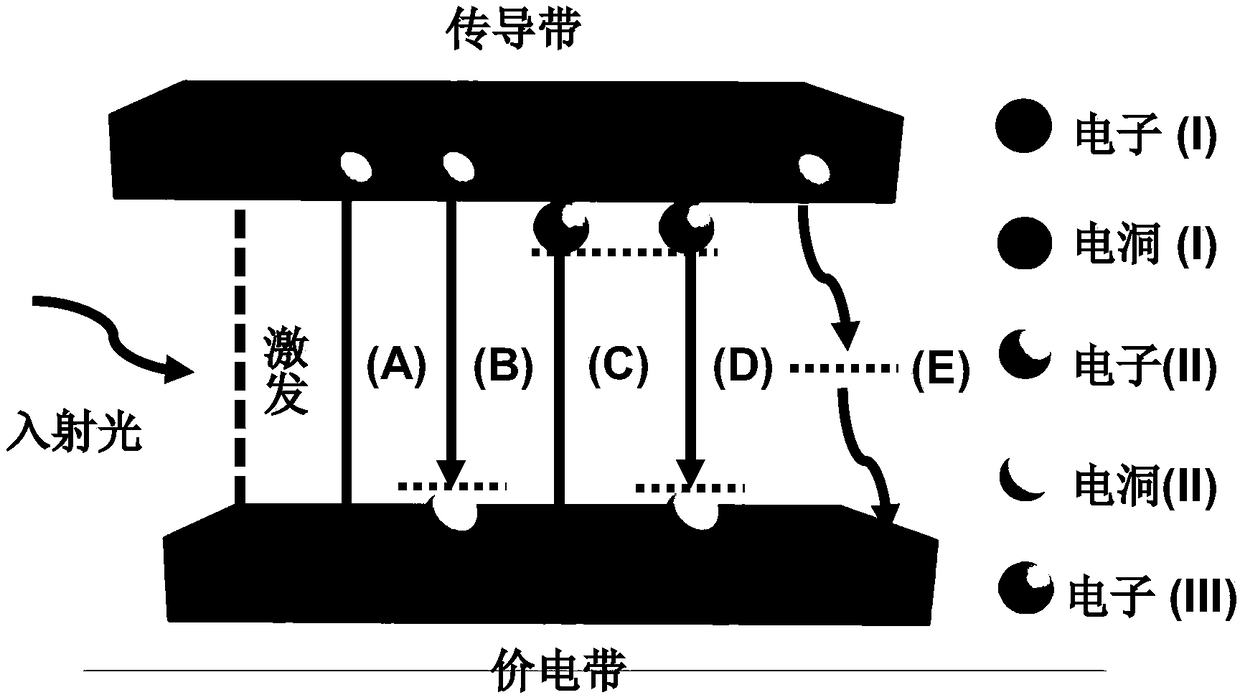

A fluorescent response and self-healing technology, applied in the field of hydrogel preparation and self-healing hydrogel preparation, to achieve the effect of convenient large-scale production, good self-healing property and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a fluorescence-responsive self-healing hydrogel, which is prepared through the following steps:

[0037] After heating to 98°C in a silicone oil bath, dissolve 10g of polyvinyl alcohol, 0.5g of chitosan, and 0.5g of lipopolysaccharide in 40g of deionized water to form a sol with a mass concentration of polyvinyl alcohol of about 20%, and heat at a constant temperature for 2 hours;

[0038] Add 50mL of sodium tetraborate solution with a concentration of 0.04mol / L and 10mL of glycerol solution to the sol, continue heating at a constant temperature to obtain a gel, heat in an oil bath at 90°C for 1 hour;

[0039] Take out the gel, inject 2L of blue fluorescent quantum dots into the gel, and press it with a 2kg weight at room temperature for 4 hours to obtain a self-healing hydrogel with fluorescent response.

Embodiment 2

[0041] This embodiment provides a fluorescence-responsive self-healing hydrogel, which is prepared through the following steps:

[0042] After heating to 98°C in a silicone oil bath, dissolve 10g of polyvinyl alcohol, 0.5g of chitosan, and 0.5g of lipopolysaccharide in 40g of deionized water to form a sol with a mass concentration of polyvinyl alcohol of about 20%, and heat at a constant temperature for 2 hours;

[0043] Add 50mL of sodium tetraborate solution with a concentration of 0.04mol / L and 10mL of glycerol solution to the sol, continue heating at a constant temperature to obtain a gel, heat in an oil bath at 90°C for 1 hour;

[0044] Take out the gel, inject 2mL of red fluorescent quantum dots into the gel, and press it with a 2kg weight at room temperature for 4 hours to obtain a fluorescence-responsive self-healing hydrogel.

Embodiment 3

[0046] This embodiment provides a fluorescence-responsive self-healing hydrogel, which is prepared through the following steps:

[0047] After heating to 98°C in a silicone oil bath, dissolve 10g of polyvinyl alcohol, 0.5g of chitosan, and 0.5g of lipopolysaccharide in 40g of deionized water to form a sol with a mass concentration of polyvinyl alcohol of about 20%, and heat at a constant temperature for 2 hours;

[0048] Add 50mL of sodium tetraborate solution with a concentration of 0.04mol / L and 10mL of glycerol solution to the sol, and continue heating at a constant temperature in an oil bath at 90°C for 1 hour;

[0049] The gel was taken out, 2 mL of green fluorescent quantum dots were injected into the gel, and pressed with a 2 kg weight at room temperature for 4 hours to obtain a fluorescently responsive self-healing hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com