A kind of rare earth treated low temperature resistant x80m pipeline steel and preparation method thereof

A pipeline steel and low temperature resistance technology, which is applied in the field of rare earth treated low temperature resistant X80M pipeline steel and its preparation, can solve the problems of increased cost and increased heat treatment process, and achieves improved low temperature resistance performance, improved service cycle and safety, and obvious advantages. The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the second embodiment of the present invention, the present invention provides a method for preparing the above rare earth treated low temperature resistant X80M pipeline steel, the method includes: smelting, continuous casting, rolling and cooling and coiling; wherein the rolling adopts two Stage controlled rolling, all of which are longitudinal rolling, the first stage is rolling in the austenite recrystallization zone, that is, the rough rolling stage, and the second stage is rolling in the austenite non-recrystallized zone, that is, the finish rolling stage.

[0034] (1) The thickness of the rough rolling intermediate billet is 68mm, the starting rolling temperature is 1160-1180°C, the inlet temperature of the final pass is ≤980°C, and the reduction rate of the final pass is ≥25%;

[0035] (2) The starting temperature of finish rolling is ≤950°C, the temperature of finish rolling is 790-830°C, the compression ratio of finish rolling is ≥3 times, and the cumulative r...

Embodiment 1

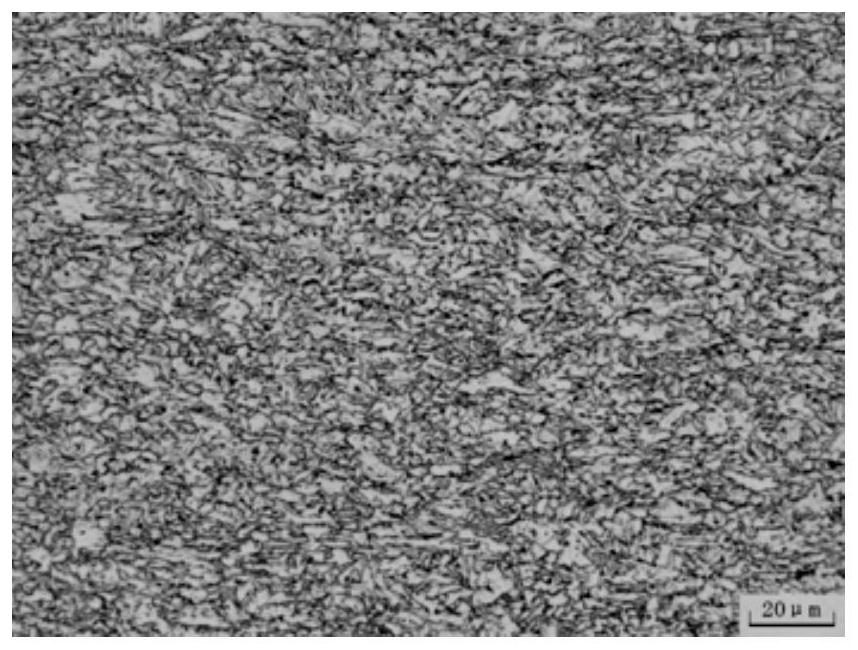

[0043] The mass percentage of the chemical composition of the steel plate is shown in Table 1. The thickness of the rough rolling intermediate billet is 68mm, the rolling start temperature is 1168°C, the entrance temperature of the final pass is 976°C, and the reduction rate of the final pass is 25.6%. The starting temperature of finish rolling is controlled at 930°C, the finish rolling temperature is 805°C, the compression ratio of finish rolling is 3.1 times, and the cumulative reduction rate is 68%. After finishing rolling, it enters the high-efficiency dense laminar flow cooling system with a cooling rate of 31°C / s and a coiling temperature of 395°C. Finally, the steel plate of the present invention can be obtained. The microstructure photograph of the steel plate that present embodiment obtains is as figure 1 As shown, the microstructure is refined and uniform, which proves the excellent mechanical properties and low temperature resistance properties of the pipeline ste...

Embodiment 2

[0045] The mass percentage of the chemical composition of the steel plate is shown in Table 1. The thickness of the rough-rolled intermediate billet is 68mm, the rolling start temperature is 1165°C, the entrance temperature of the final pass is 972°C, and the reduction rate of the final pass is 25.6%. The finish rolling start temperature is 936°C, the finish rolling temperature is 815°C, the finish rolling reduction ratio is 3.1 times, and the cumulative reduction ratio is 68%. After finishing rolling, it enters the high-efficiency dense laminar cooling system with a cooling rate of 32°C / s and a coiling temperature of 405°C. Finally, the steel plate of the present invention can be obtained.

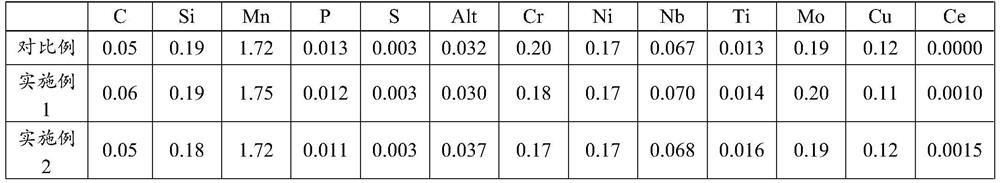

[0046] Table 1: Chemical composition and mass percentage (%) of pipeline steel in various embodiments and comparative examples

[0047]

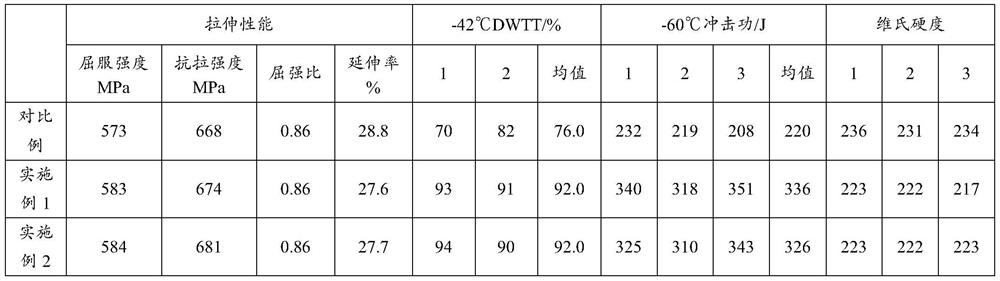

[0048] Table 2 below shows the mechanical properties of the plate coils corresponding to Example 1-2 of the present invention and Comparative Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com