An automatic injection process for jeans

A kind of jeans and automatic technology, which is applied in the direction of textiles and papermaking, textile materials treatment, partial treatment of textile materials, etc. It can solve the problems of staff health hazards, respiratory discomfort or allergies, harsh working environment, etc., and achieve jet quality Good consistency, high production efficiency, and the effect of preventing environmental pollution and harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing:

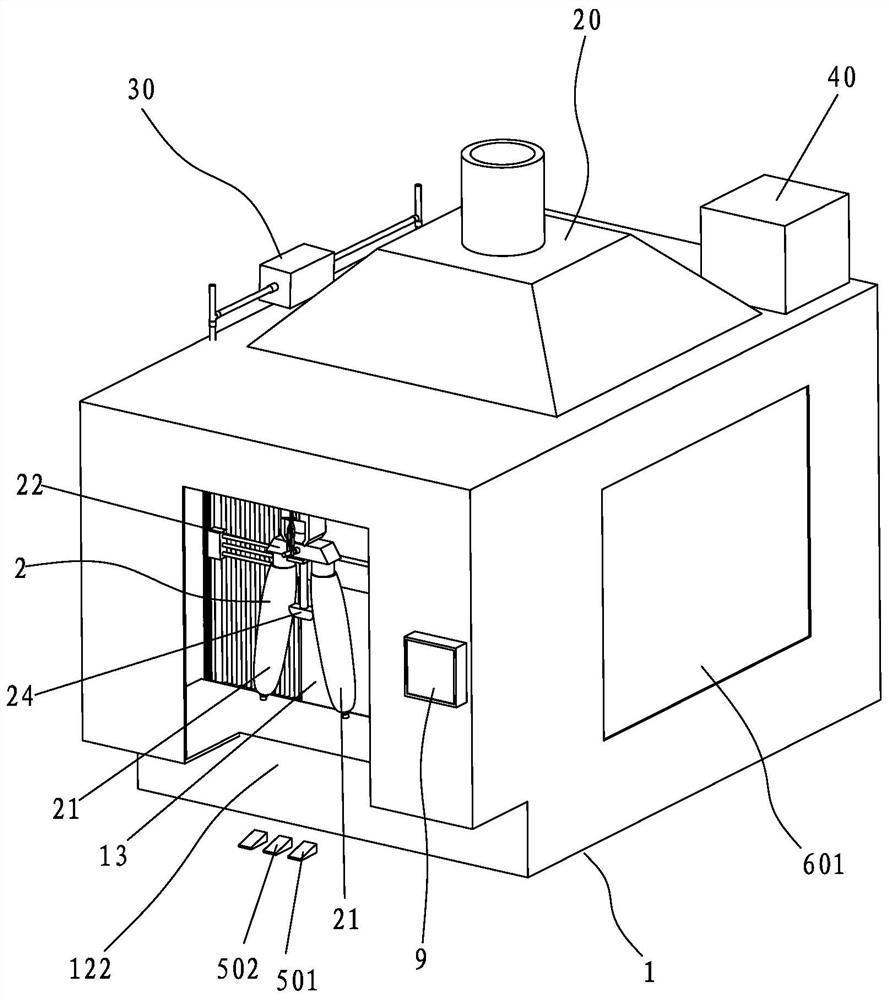

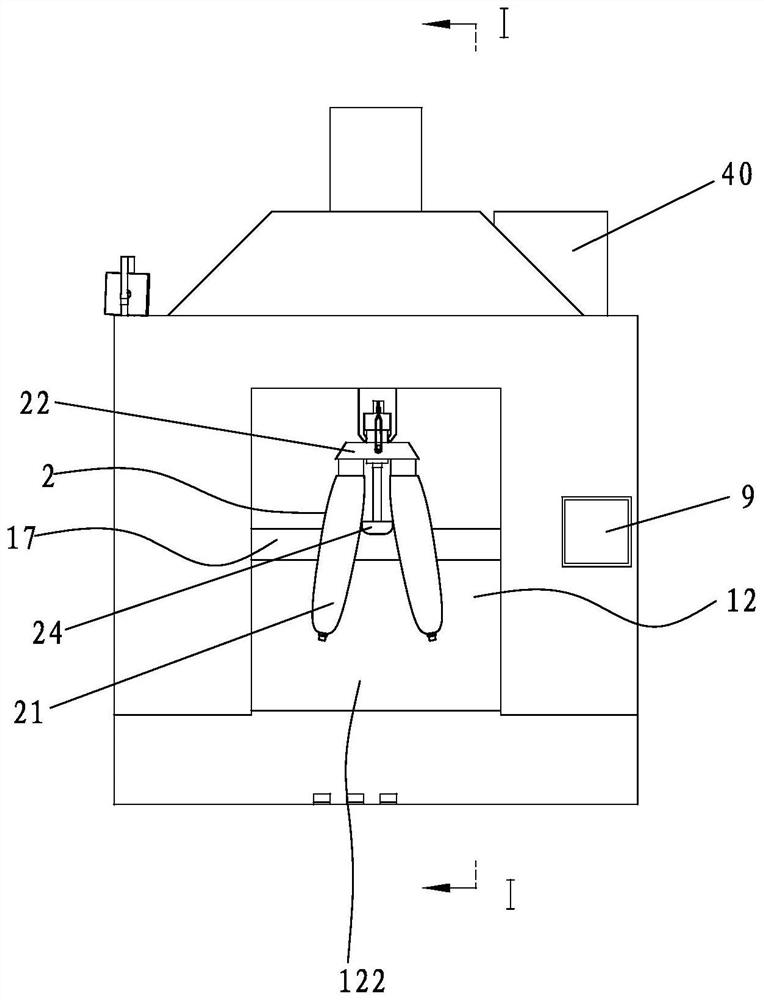

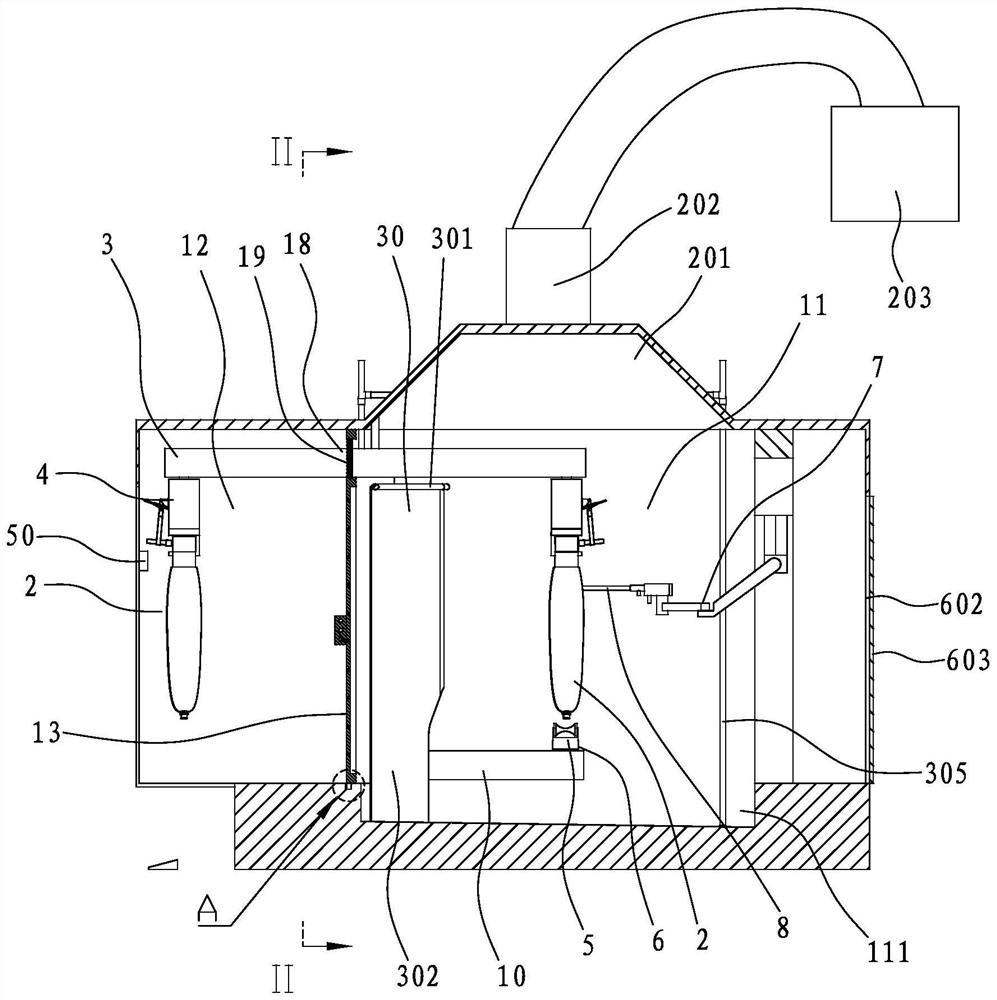

[0060] Such as figure 1 and Figure 17 A kind of equipment that is used for automatic spraying of jeans as shown, comprises casing 1, and described casing 1 is provided with the injection chamber 11 that is used for spraying and is used for the trousers chamber 12 that disassembles jeans, and described casing 1 It is provided with a rubber wave device 2 for inserting the jeans and expanding and fixing the jeans on the outside after inflation, and a conversion device for driving the rubber wave device 2 to switch between the injection chamber 11 and the trouser chamber 12 3. There is a hanging device 4 between the rubber wave device 2 and the conversion device 3 that connects the two and hangs the rubber wave device 2. The suspension device 4 is connected to the conversion device 3 in rotation. The cavity 11 is provided with a stretching device 5 capable of stretching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com