Modular internal concave type flame retardant device

A flame retardant, modular technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of bulky, low quenching and extinguishing efficiency, etc., to increase the heat transfer area and high quenching and extinguishing efficiency , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

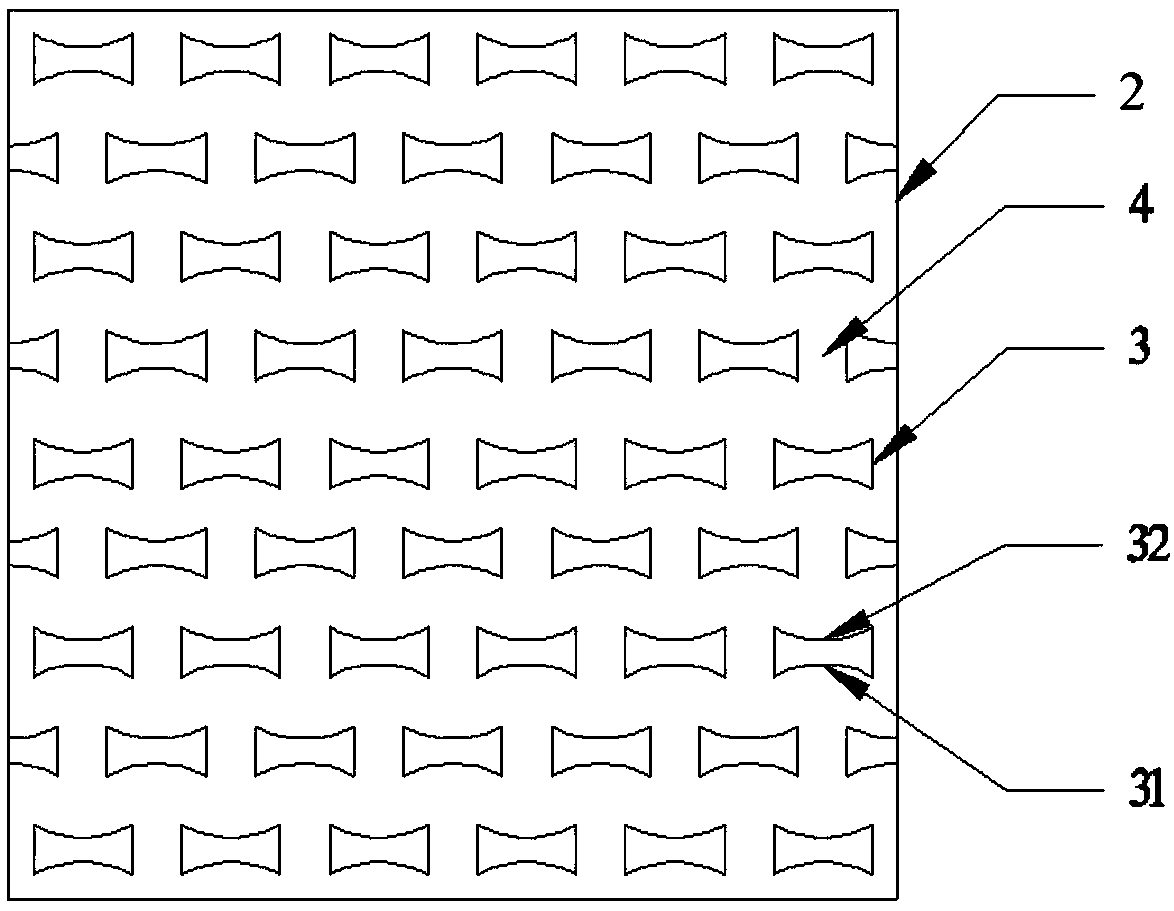

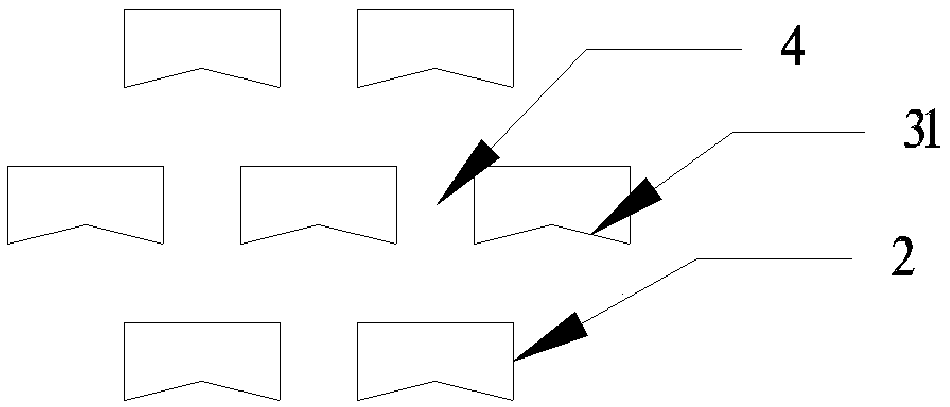

[0029] Such as Figure 1-4 As shown in and 11, a modular concave flame retardant of this embodiment includes more than one single three-dimensional flame retardant channel 1 formed by superimposing two flame retardant sheets 2, and the flame retardant sheet 2 is provided with There is a spoiler column 3, and the spoiler column 3 includes a windward side 31 and a leeward side 32; the windward side 31 of the spoiler column 3 is a concave structure, and the previous row of spoiler columns 3 Located in the front center of the gap 4 between two adjacent spoiler posts 3 in the rear row, and the gap between the two adjacent spoiler posts 3 in the rear row is smaller than the spoiler posts 3 in the previous row width.

[0030] The concave structure adopts a triangular concave (such as figure 2 shown) or trapezoidal concave (as image 3 shown), or arc concave (such as Figure 4 shown).

[0031] The gap 4 between two adjacent spoiler columns 3 is the flow path of the deflagration ...

Embodiment 2

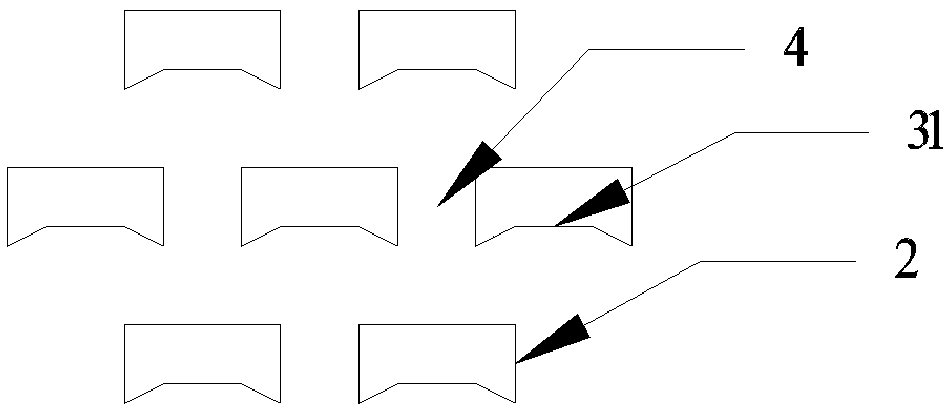

[0035] Such as figure 1 , as shown in 5-7 and 12, a modular concave flame retardant of this embodiment includes more than one single three-dimensional flame retardant channel 1 formed by superimposing two flame retardant sheets 2, and the flame retardant A spoiler column 3 is provided on the sheet 2, and the spoiler column 3 includes a windward side 31 and a leeward side 32; the leeward side 32 of the spoiler column 3 is a concave structure, and the front row The spoiler post 3 is located in the front center of the gap 4 between two adjacent spoiler posts 3 in the rear row, and the gap between the two adjacent spoiler posts 3 in the rear row is smaller than that of the previous row The width of spoiler column 3.

[0036] The concave structure adopts (such as Figure 5 shown) or trapezoidal concave (as Figure 6 shown) or curved concave (such as Figure 7 shown).

[0037] The gap 4 between two adjacent spoiler columns 3 is the flow path of the deflagration flame.

[0038]...

Embodiment 3

[0041] Such as figure 1 , 8-10 and 11, 12, a modular concave flame retardant of this embodiment includes more than one single three-dimensional flame-retardant channel 1 formed by superimposing two flame-retardant sheets 2, the described The flame-retardant sheet 2 is provided with a spoiler column 3, and the spoiler column 3 includes a windward side 31 and a leeward side 32; the windward side 31 and the leeward side 32 of the spoiler column 3 are both concave structures ; The front row of spoiler posts 3 is located in the front center of the gap 4 between two adjacent spoiler posts 3 in the rear row, and the gap between the two adjacent spoiler posts 3 in the rear row is less than The width of the spoiler columns 3 in the preceding row.

[0042] The concave structure adopts a triangular concave (such as Figure 8 shown) or trapezoidal concave (as Figure 9 shown) or curved concave (such as Figure 10 shown).

[0043] The gap 4 between two adjacent spoiler columns 3 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com