Self-operated differential pressure control valve

A self-operated differential pressure and differential pressure valve technology, applied in the field of self-operated differential pressure control valves, can solve the problems of automatic valve plug stuck, large differential pressure error, gas storage in the pressure-sensitive element cavity, etc., and increase the free length of the spring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

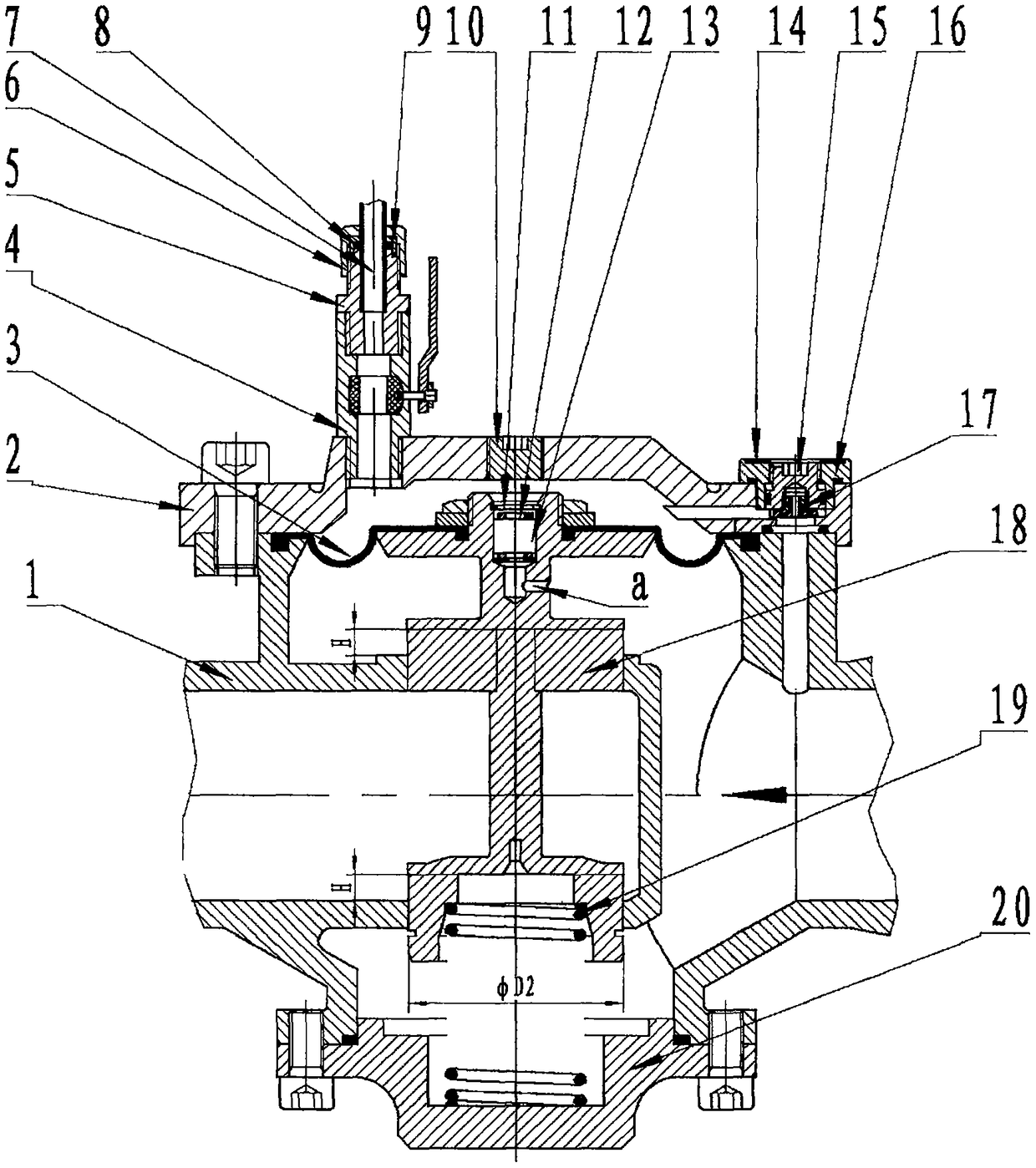

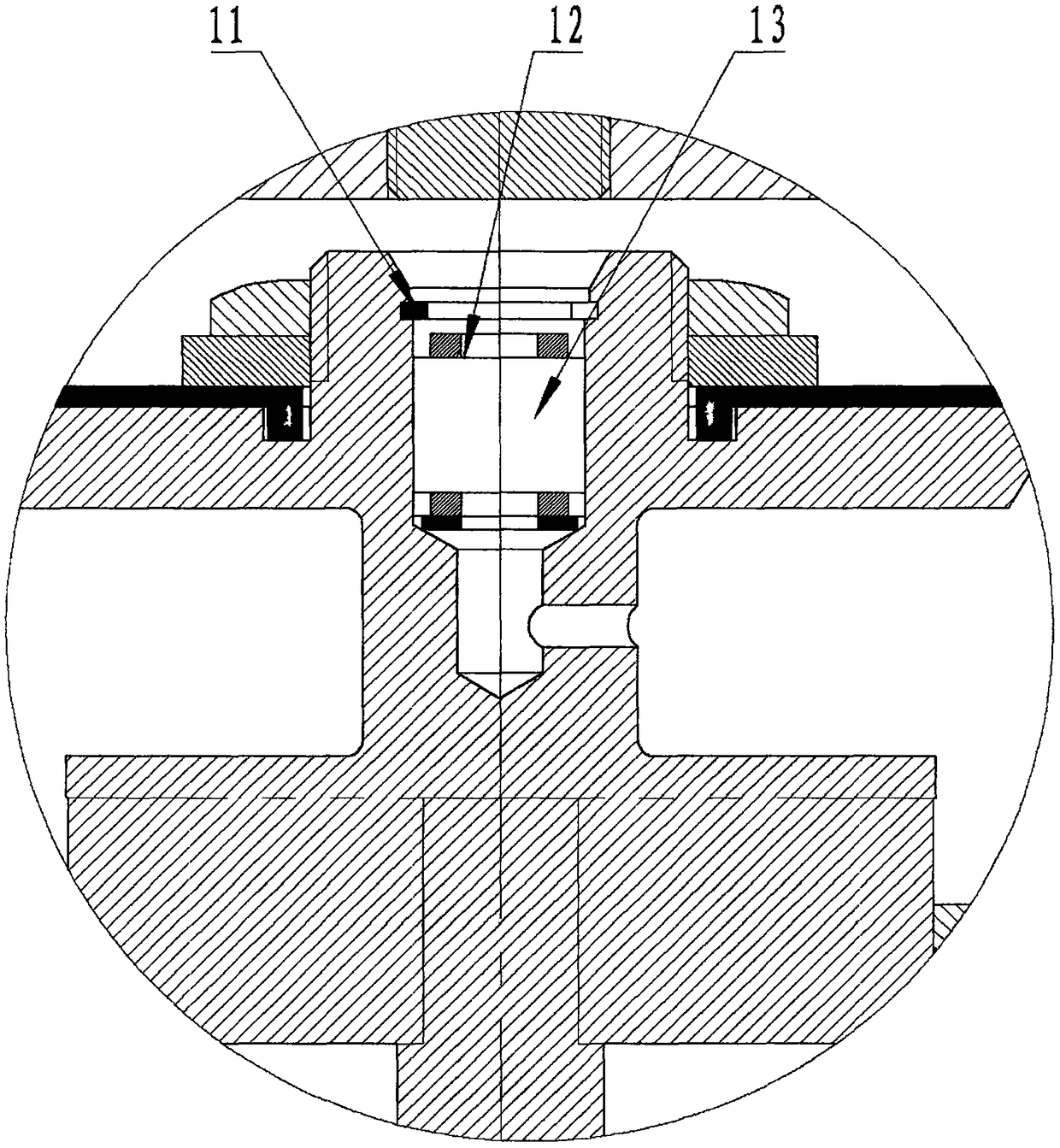

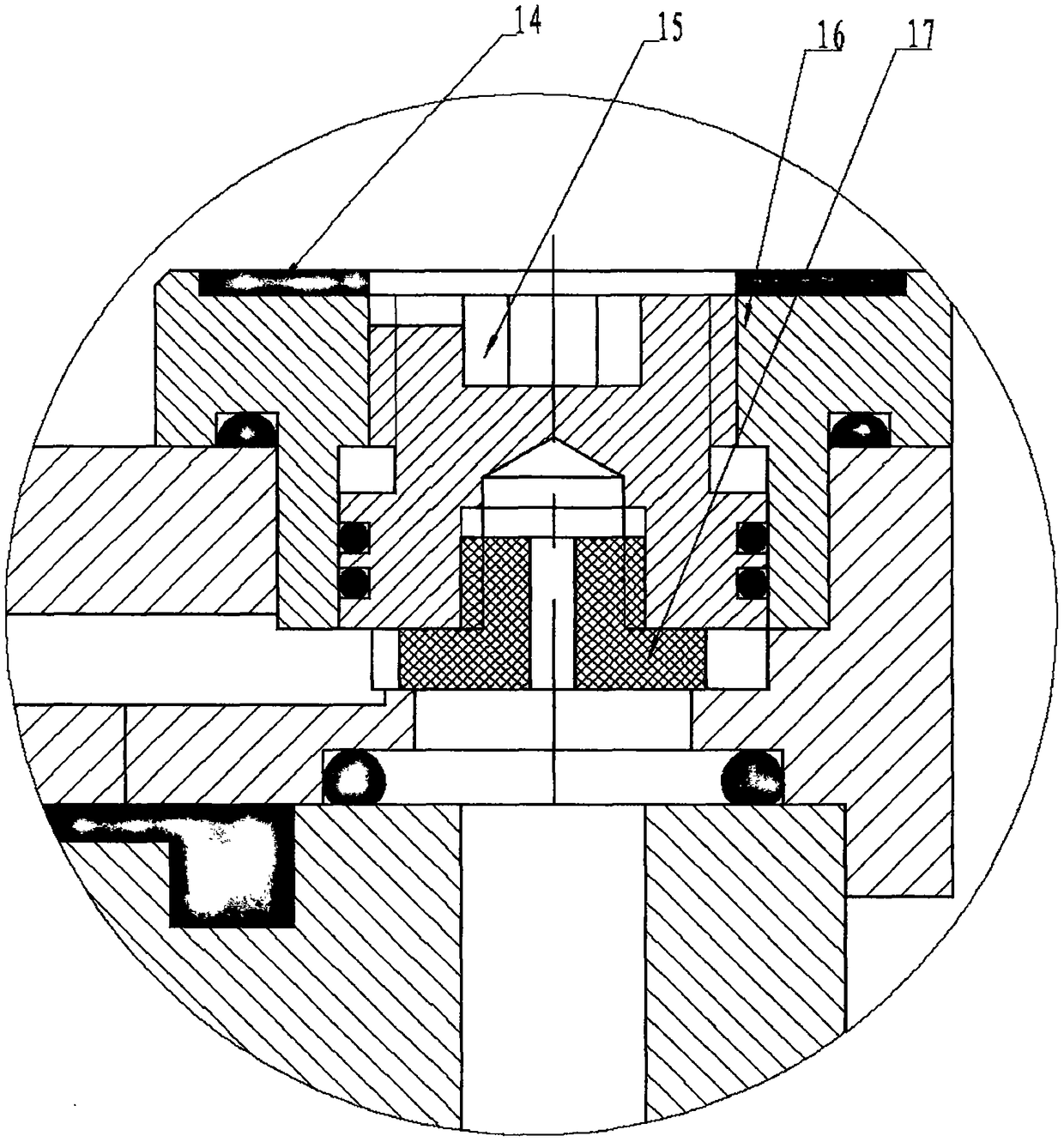

[0044] A self-operated differential pressure control valve for fluid medium control, consisting of a valve body 1, a valve cover 2, a spring barrel 20, an exhaust screw 10, an opening and closing mechanism, a balancing device, a differential pressure adjusting device and a pressure guiding device, Valve body 1, bonnet 2, and spring barrel 20 constitute the shell part of the differential pressure valve. The opening and closing mechanism includes a pressure-sensitive element 3, a main spring 19, and a valve plug 18, which are placed in the valve body 1. The pressure-sensitive element 3 and the bonnet 2 Constitute the chamber of the pressure-sensing element, the balance device includes two balance springs 12, the elastic retaining ring 11 for the hole and the float 13 are placed in the valve plug 18, and the pressure difference adjustment device consists of a pressure regulating valve body 16, a pressure regulating valve stem 15, a sealing The pad 17 and the display panel 14 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com