Double-stage compression heat pump circulation system for deeply condensing steam exhaust

A deep condensation and two-stage compression technology, applied in heat pumps, fluid circulation arrangements, refrigerators, etc., can solve the problems of low coefficient of performance and efficiency of heat pumps, low evaporation temperature of heat pumps, poor energy saving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

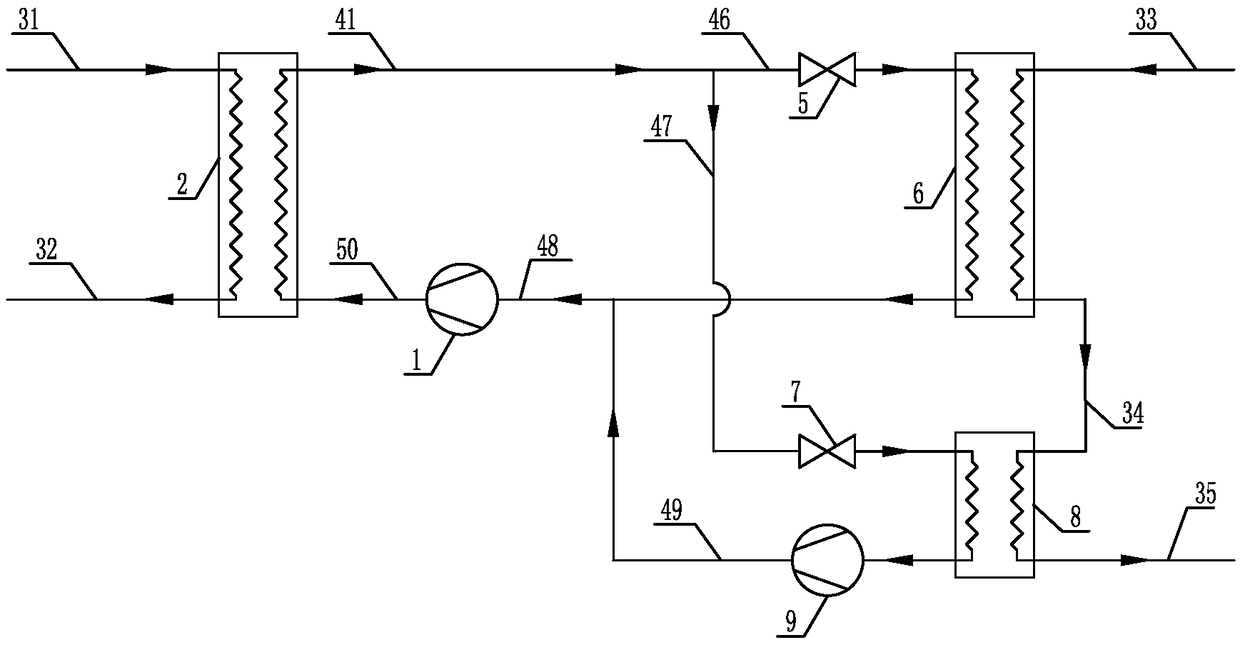

[0051] Specific implementation mode one: combine figure 1 This embodiment is described. A two-stage compression heat pump cycle system for deep condensation of exhaust gas in this embodiment includes a first compressor 1, a heat pump condenser 2, a second throttling expansion valve 5, a heat pump first evaporator 6, The third throttling expansion valve 7, the second evaporator 8 of the heat pump, the second compressor 9, the first heat transfer medium pipeline 31, the second heat transfer medium pipeline 32, the first exhaust steam pipeline 33, the second exhaust steam pipeline Steam pipeline 34, third exhaust steam pipeline 35, first refrigerant pipeline 41, sixth refrigerant pipeline 46, seventh refrigerant pipeline 47, eighth refrigerant pipeline 48, ninth refrigerant pipeline Road 49 and the tenth refrigerant pipeline 50,

[0052] The outlet end of the first heat transfer medium pipeline 31 is connected to the heat medium inlet end of the heat pump condenser 2, and the he...

specific Embodiment approach 2

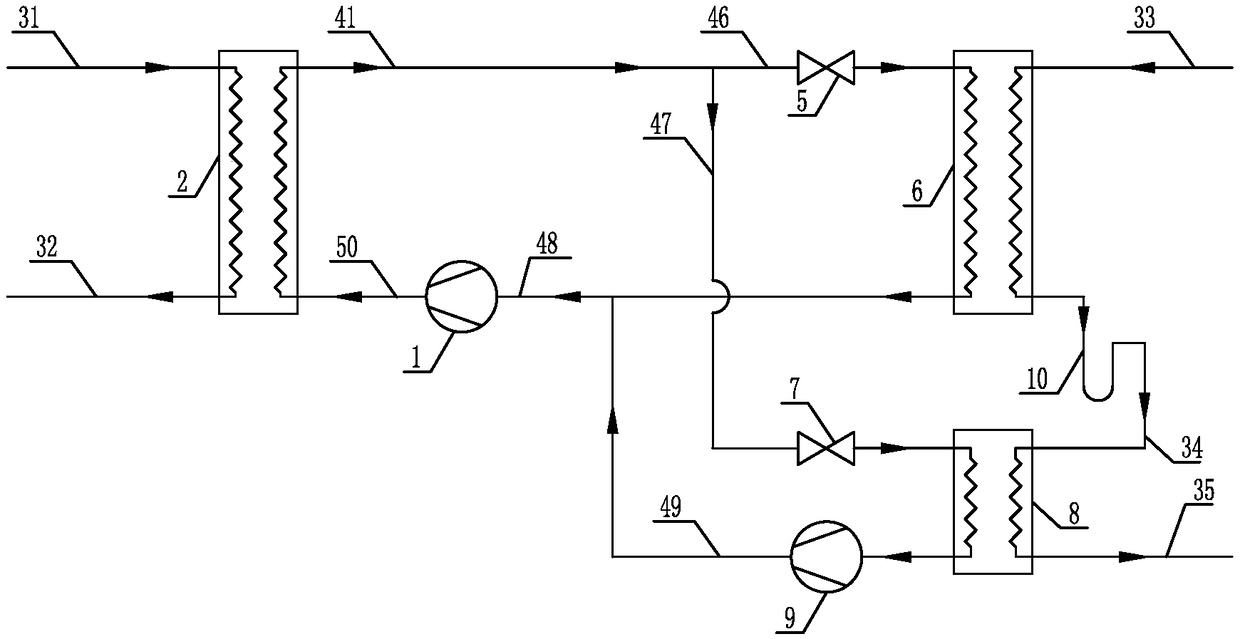

[0066] Specific implementation mode two: combination figure 2 This embodiment is described. A two-stage compression heat pump cycle system for deep condensation of exhaust gas in this embodiment includes a first compressor 1, a heat pump condenser 2, a second throttling expansion valve 5, a heat pump first evaporator 6, The third throttling expansion valve 7, the second evaporator 8 of the heat pump, the second compressor 9, the condensate U-bend 10, the first heat transfer medium pipeline 31, the second heat transfer medium pipeline 32, the first exhaust steam Pipeline 33, second exhaust steam pipeline 34, third exhaust steam pipeline 35, first refrigerant pipeline 41, sixth refrigerant pipeline 46, seventh refrigerant pipeline 47, eighth refrigerant pipeline 48. The ninth refrigerant pipeline 49 and the tenth refrigerant pipeline 50,

[0067] The outlet end of the first heat transfer medium pipeline 31 is connected to the heat medium inlet end of the heat pump condenser 2,...

specific Embodiment approach 3

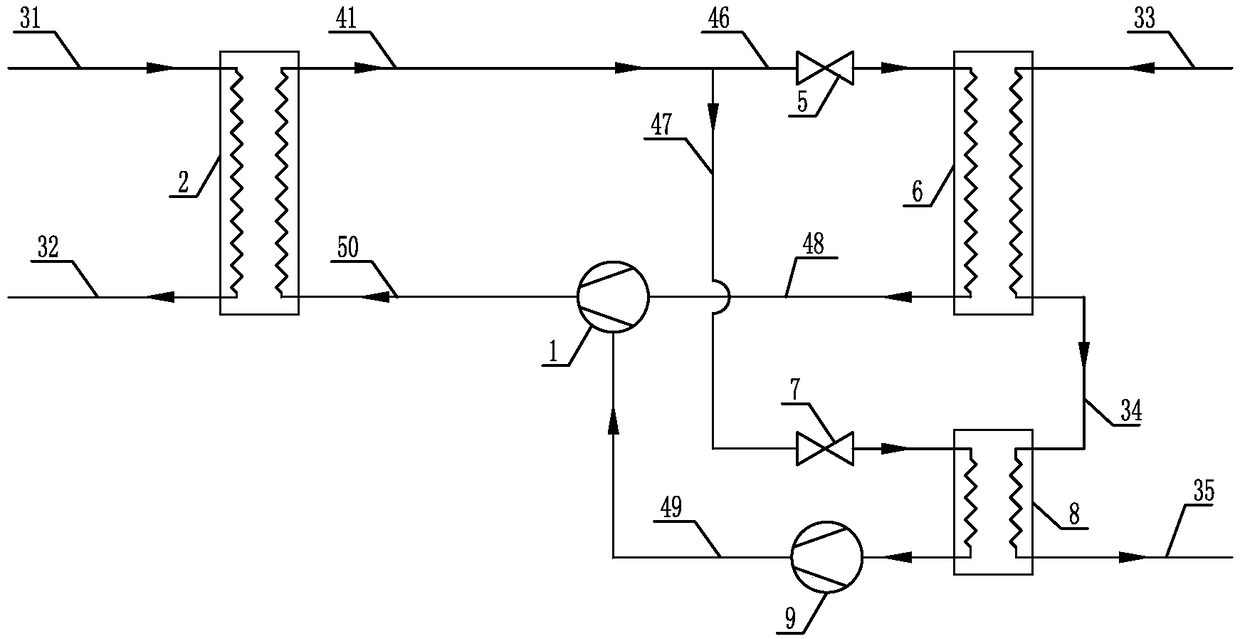

[0071] Specific implementation mode three: combination image 3 This embodiment is described. A two-stage compression heat pump cycle system for deep condensation of exhaust gas in this embodiment includes a first compressor 1, a heat pump condenser 2, a second throttling expansion valve 5, a heat pump first evaporator 6, The third throttling expansion valve 7, the second evaporator 8 of the heat pump, the second compressor 9, the first heat transfer medium pipeline 31, the second heat transfer medium pipeline 32, the first exhaust steam pipeline 33, the second exhaust steam pipeline Steam pipeline 34, third exhaust steam pipeline 35, first refrigerant pipeline 41, sixth refrigerant pipeline 46, seventh refrigerant pipeline 47, eighth refrigerant pipeline 48, ninth refrigerant pipeline Road 49 and the tenth refrigerant pipeline 50,

[0072] The outlet end of the first heat transfer medium pipeline 31 is connected to the heat medium inlet end of the heat pump condenser 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com