Two-stage-compression heat pump double-effect evaporation and condensation system

A concentration system, double-effect evaporation technology, applied in multi-effect evaporation, evaporation, evaporator accessories, etc., can solve the problem of high outlet temperature of two-effect juice vapor condensate water, high system energy consumption, and difficulty in vacuum degree of double-effect evaporation and concentration system maintain higher issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

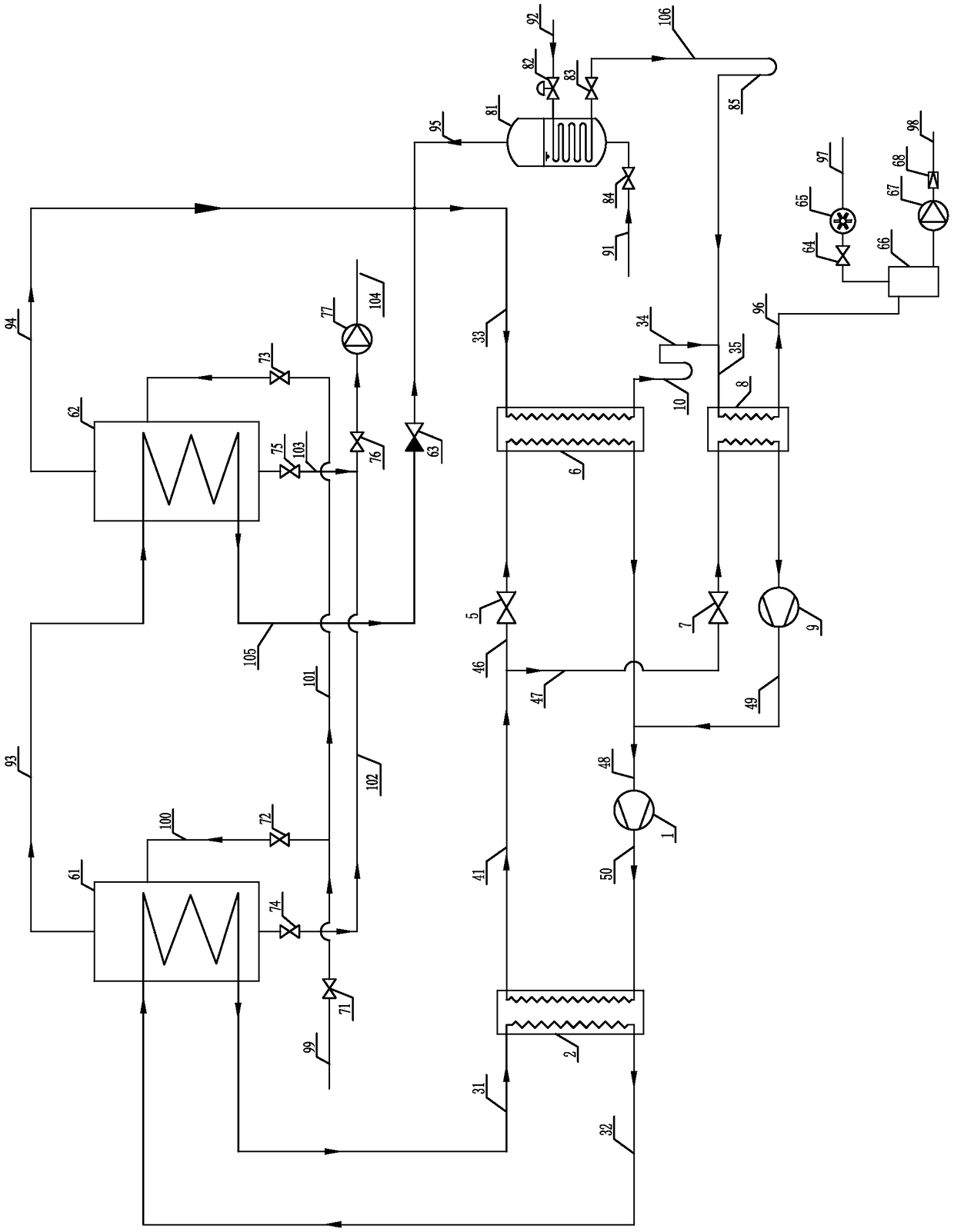

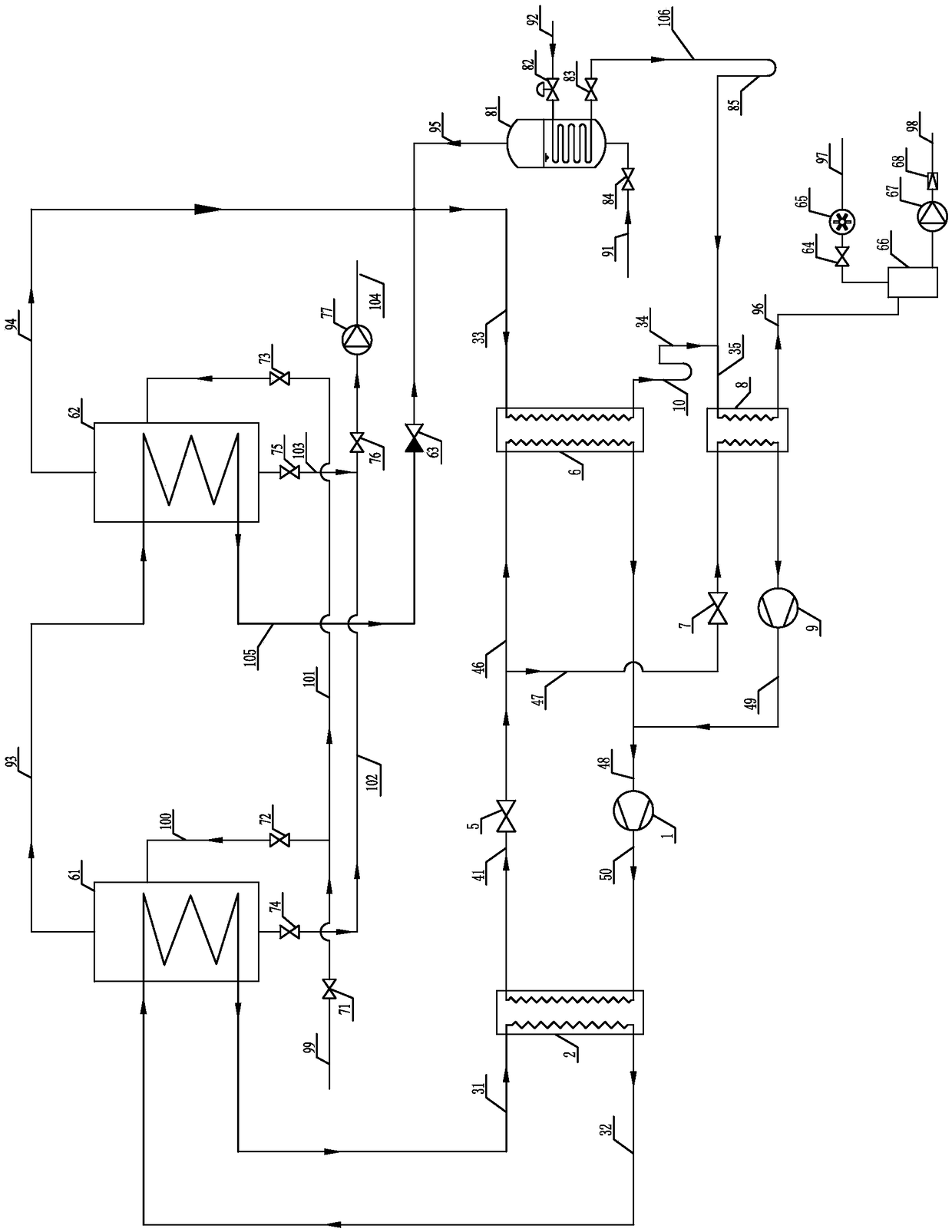

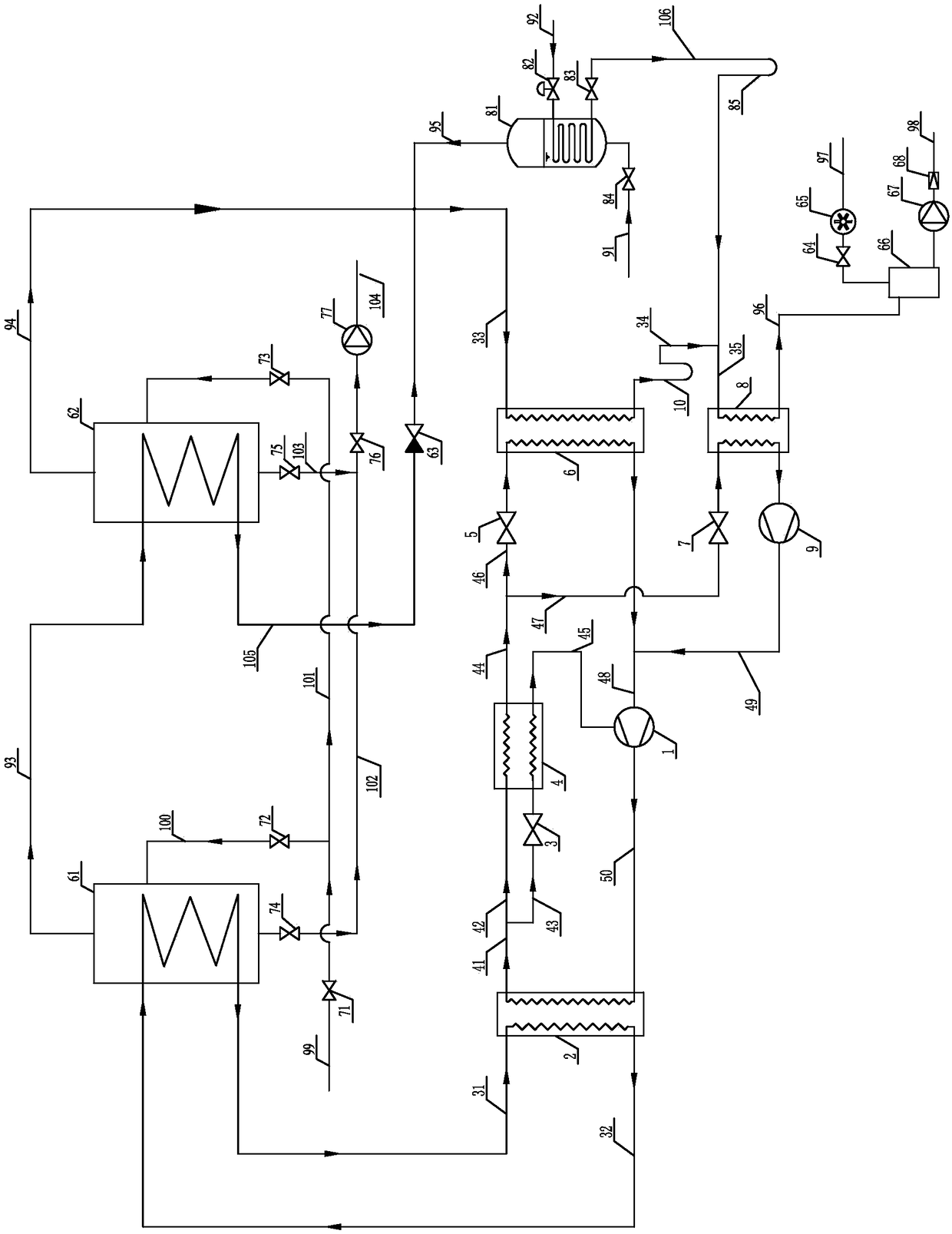

[0054] Specific implementation mode one: combine figure 1 Describe this embodiment, a two-stage compression heat pump double-effect evaporation and concentration system described in this embodiment includes a first compressor 1, a heat pump condenser 2, a second throttling expansion valve 5, a heat pump first evaporator 6, a second Three-throttle expansion valve 7, heat pump second evaporator 8, second compressor 9, first intermediary water circulation pipeline 31, second intermediary water circulation pipeline 32, first total exhaust steam pipeline 33, second total exhaust steam Pipeline 34, third total exhaust steam pipeline 35, first refrigerant pipeline 41, sixth refrigerant pipeline 46, seventh refrigerant pipeline 47, eighth refrigerant pipeline 48, ninth refrigerant pipeline Road 49, tenth refrigerant pipeline 50, first-effect evaporator 61, second-effect evaporator 62, vacuum control valve 64, vacuum pump 65, condensate collection tank 66, condensate discharge pump 67,...

specific Embodiment approach 2

[0077] Specific implementation mode two: combination figure 1 To illustrate this embodiment, an effective condensate water throttling device 63 is provided on the second first-effect juice vapor pipeline 105 in this embodiment. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0078] In order to fully recover and utilize the waste heat of the condensed water of the first-effect juice vapor, the condensed water of the first-effect juice vapor and the second-effect juice vapor are merged into the first evaporator 6 of the heat pump for heat recovery. Since the pressure of the first-effect evaporator 61 is higher than that of the second-effect evaporator 62, a first-effect condensate throttling device 63 is installed on the second first-effect juice vapor pipeline 105 to control the first-effect evaporator 61 and the second-effect evaporator. The pressure difference between the effect evaporation tanks 62 (also controls the bo...

specific Embodiment approach 3

[0079] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the second total exhaust steam pipeline 34 in this embodiment is provided with a first condensate water U-bend 10 , and the second start-up raw steam pipeline 106 is provided with a second condensate water U-shaped bend 85 . The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0080] The purpose of arranging the first condensate water U-shaped bend 10 and the second condensate water U-shaped bend 85 is to block the exhaust steam that is not completely condensed in the first evaporator 6 of the heat pump or the exhaust gas that is not completely condensed in the starter 81 The raw steam enters the second evaporator 8 of the heat pump to avoid a sharp increase in the refrigerant evaporation in the second evaporator 8 of the heat pump, thereby avoiding a sharp increase in the load of the second compressor 9 and causing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com