Rock test block fixing device for point load test

A technology of rock test block and fixing device, which is applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the difficulty of accurately evaluating and controlling the clamping force of rock test block by clamping pad, increasing Test time, impact on test results and other issues, to eliminate the possibility of caving and long-distance movement, easy operation, and ensure the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

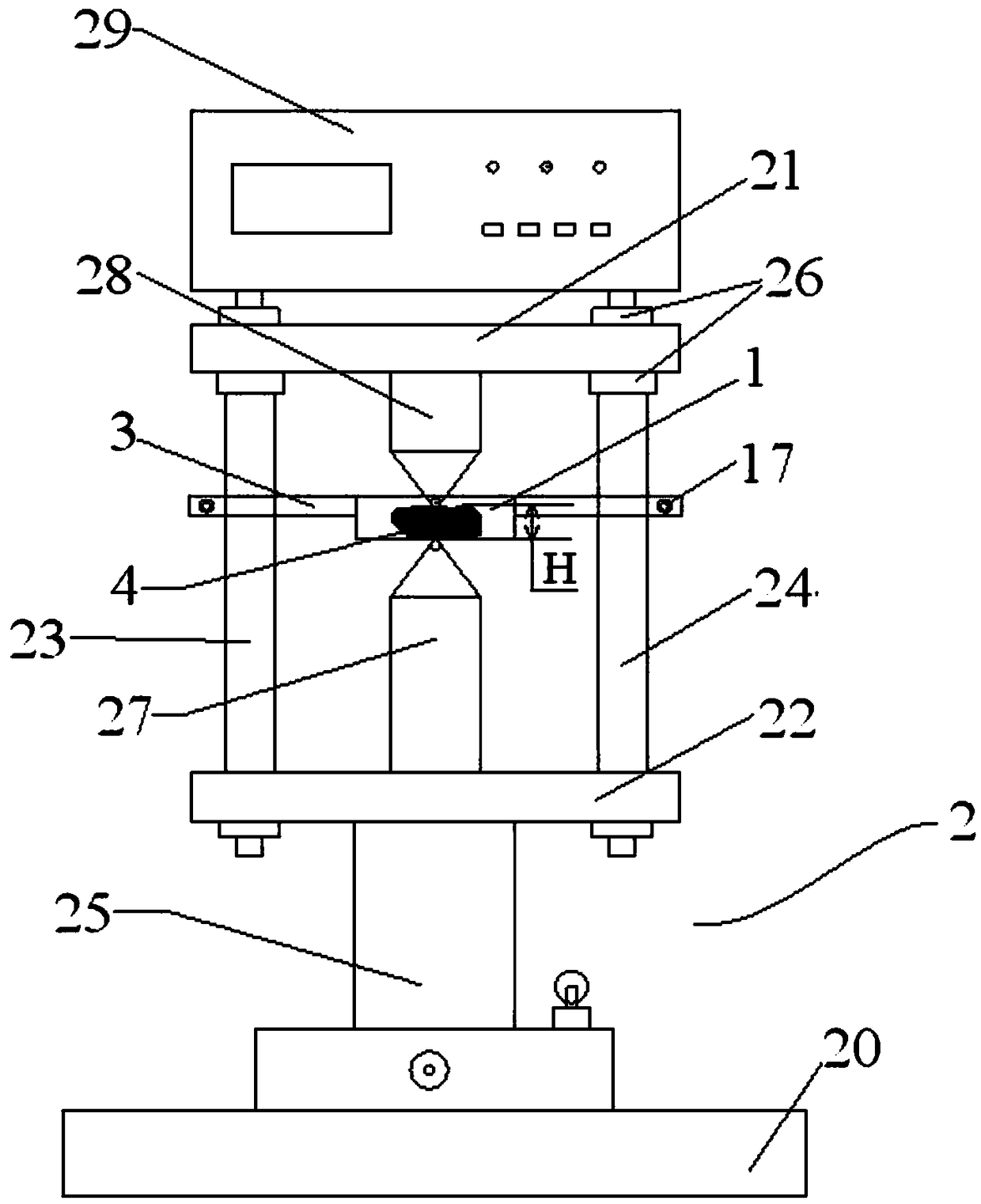

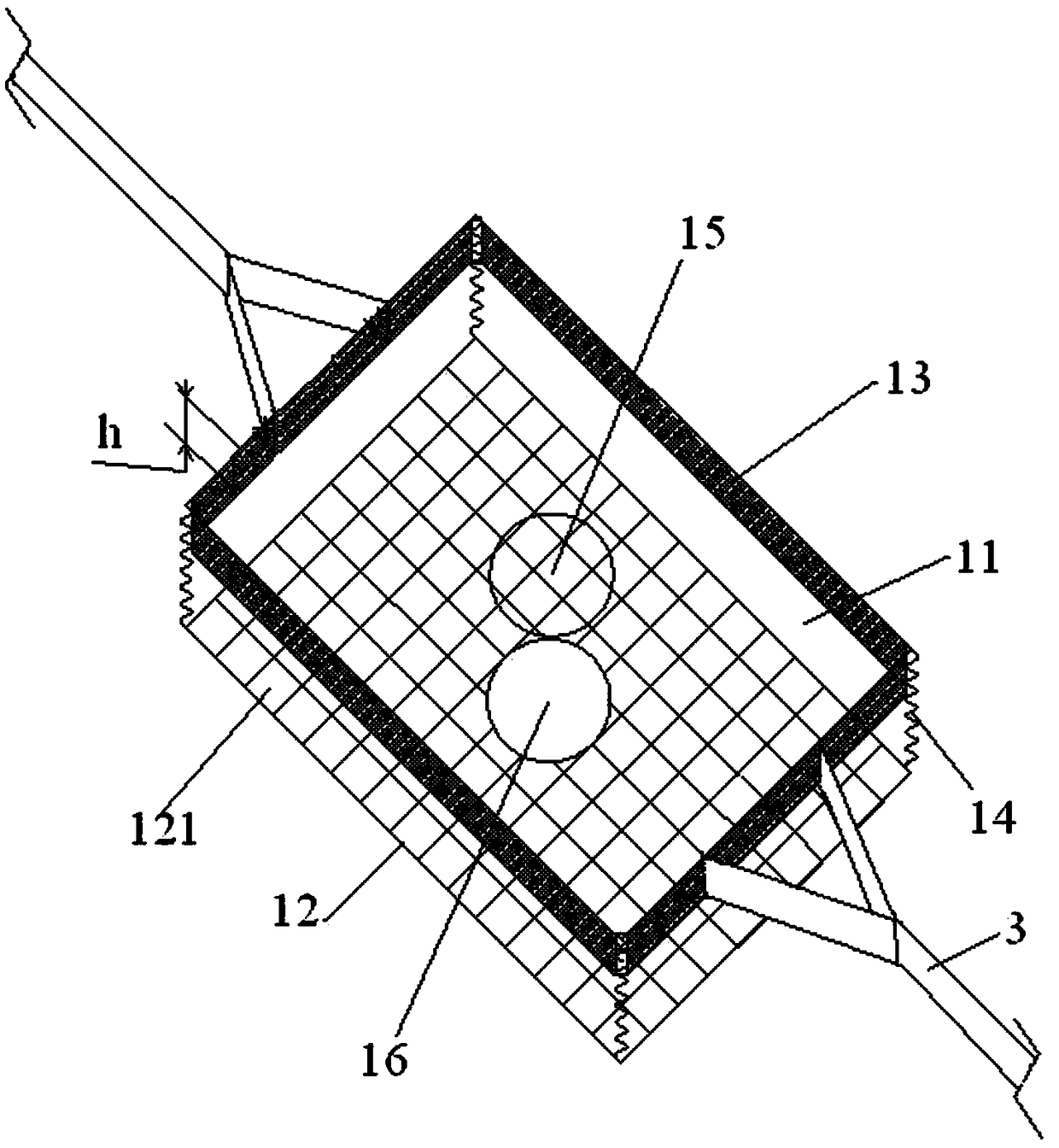

[0036] A kind of rock test block fixing device for point load test, this rock test block fixing device is arranged on the hydraulic type point load tester 2, see figure 1 , the point load tester includes a base 20 and a jack 25 arranged on the base, a support frame is fixedly connected to the large oil cylinder body of the jack, and the support frame includes an upper horizontal support 21, a lower horizontal support 22, and a left vertical support rod 23 And the right vertical support rod 24, the left vertical support rod and the right vertical support are arranged in parallel and the lower ends of the two are respectively fixedly connected to the two ends of the lower horizontal support, and the upper end is set in the preset guide hole of the upper horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com