Point load tester and point load testing method

A point load and tester technology, applied in instruments, scientific instruments, using stable tension/compression to test the strength of materials, etc., can solve the problem that the clamping pad is difficult to accurately evaluate and control the clamping force of the rock test block and affect the test Results, test results and other issues, to eliminate the possibility of avalanche and long-distance movement, convenient operation, and enhance the effect of test safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

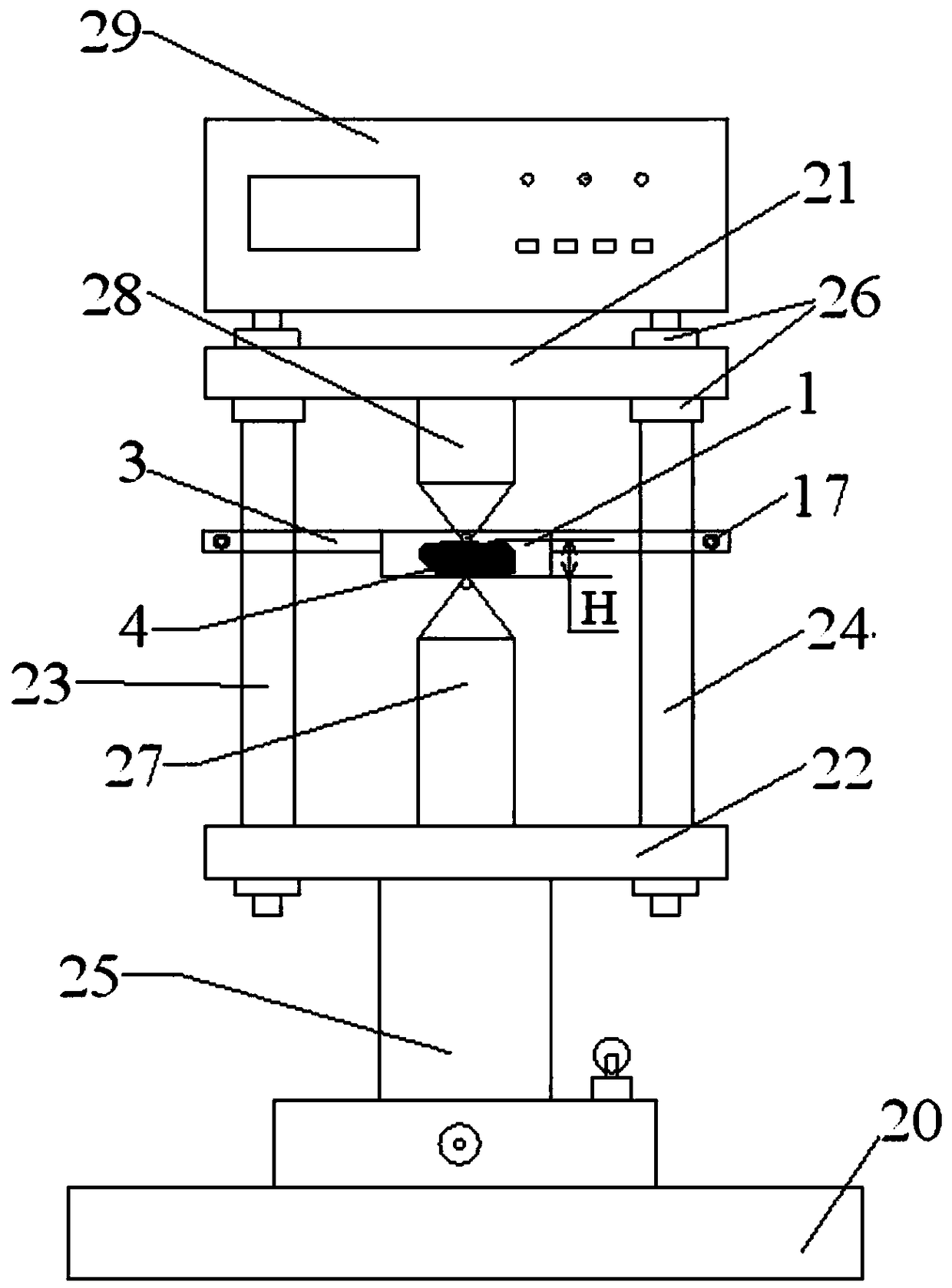

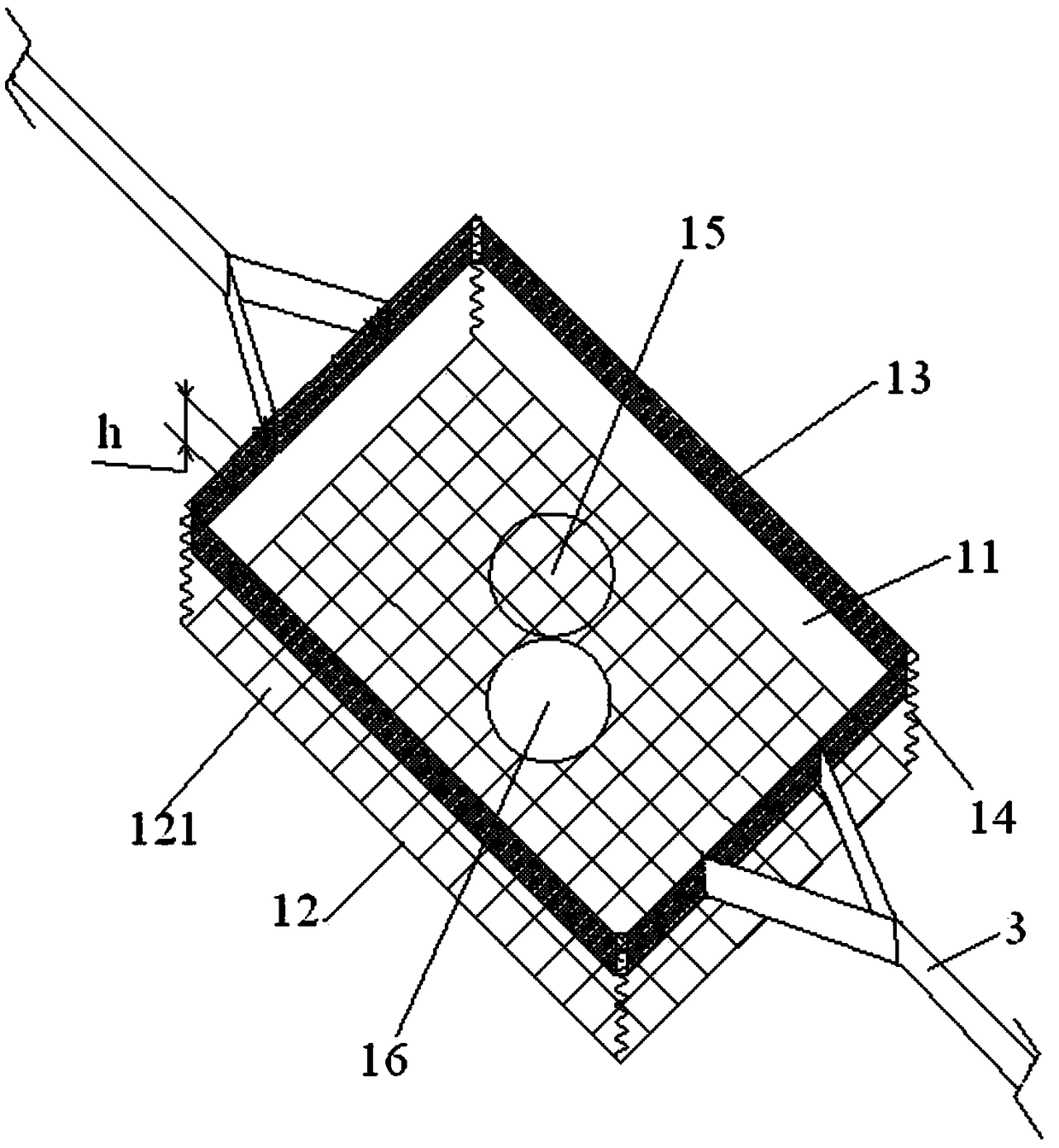

[0042] A point load tester, comprising a rock test block fixing device, the rock test block fixing device is arranged on the main body 2 of the hydraulic point load tester, see figure 1 , the point load tester also includes a supporting device, a base 20 and a loading device arranged on the base. In the present embodiment, the loading device includes a jack 25, and the large oil cylinder body of the jack is fixedly connected with the supporting device, and the supporting device Comprising a horizontal support and a vertical support, the horizontal support includes an upper horizontal support 21 and a lower horizontal support 22, the vertical support includes a left vertical support rod 23 and a right vertical support rod 24, and the left vertical support ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com