Novel carbon-coated aluminum foil blank-left coating device

A white coating and carbon coating technology, which is applied to the device, coating, electrode collector coating and other directions of coating liquid on the surface, which can solve the problem of long production cycle, time-consuming and laborious disassembly and installation of the coating roller, and the need for replacement. and other problems to achieve the effect of saving raw materials, improving work efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

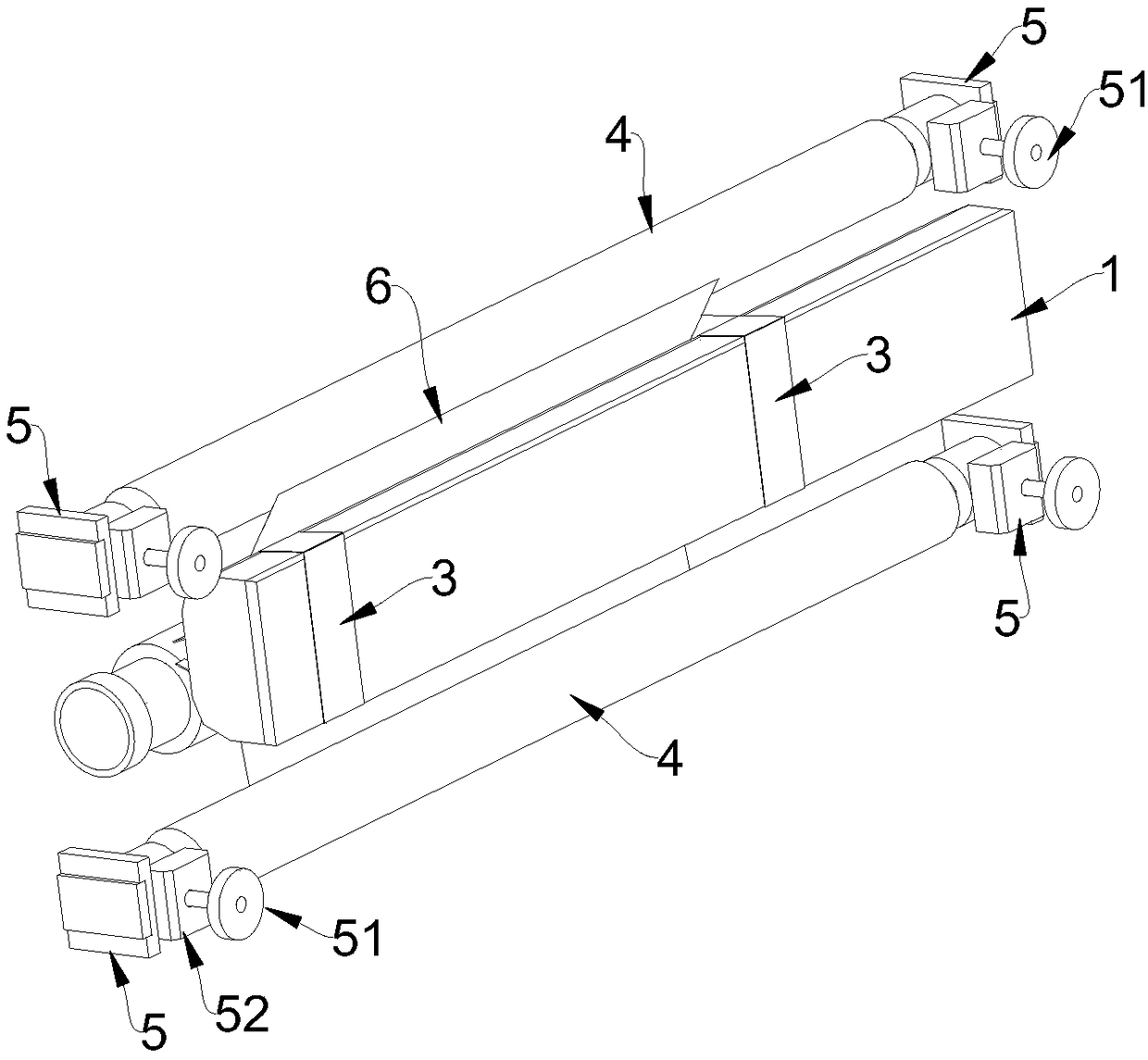

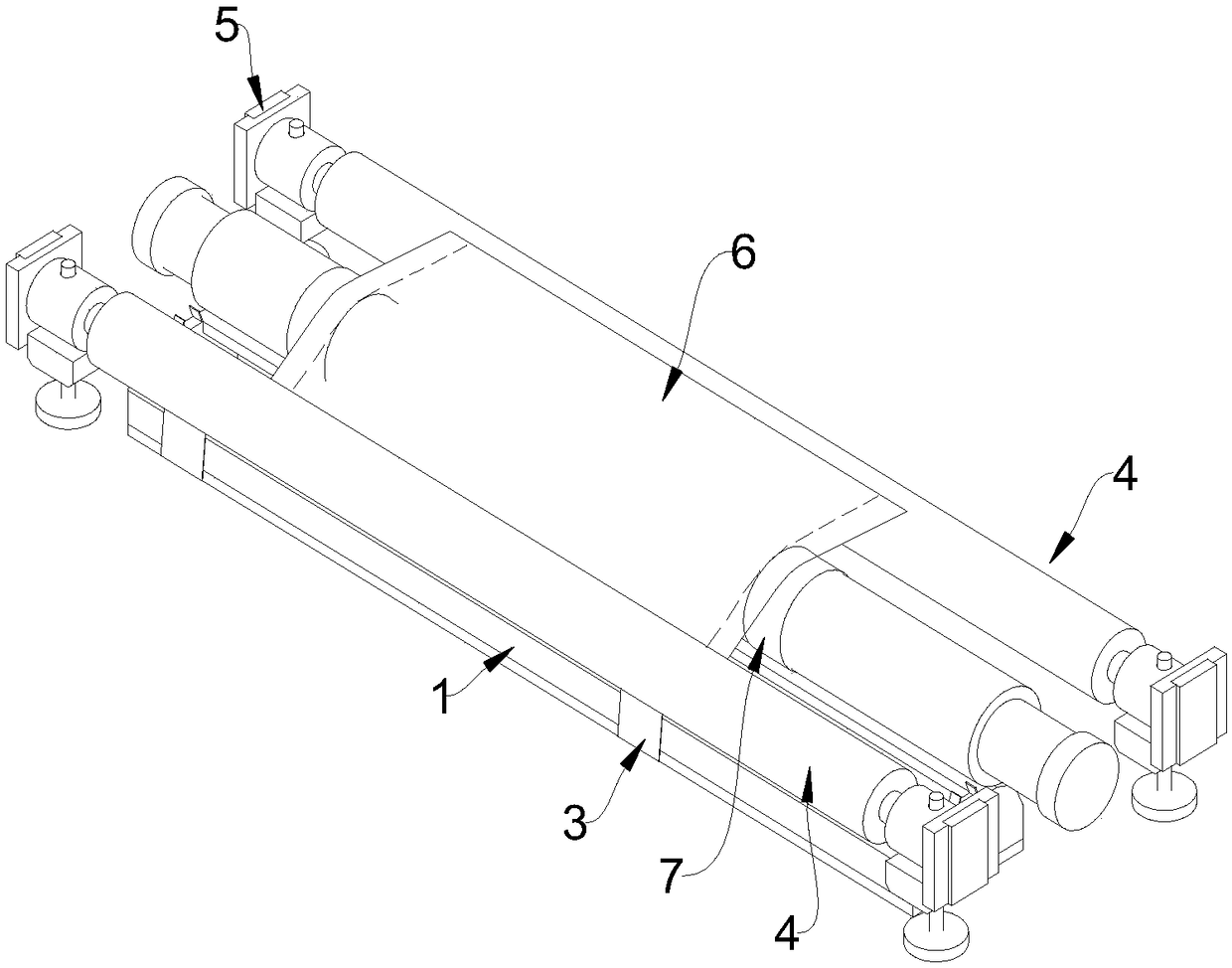

[0021] Figure 1 to Figure 4 A novel carbon-coated aluminum foil blank coating device according to an embodiment of the present invention is schematically shown. As shown in the figure, the device mainly includes a paint tank 1, a coating roller 2, and a regulating roller 4.

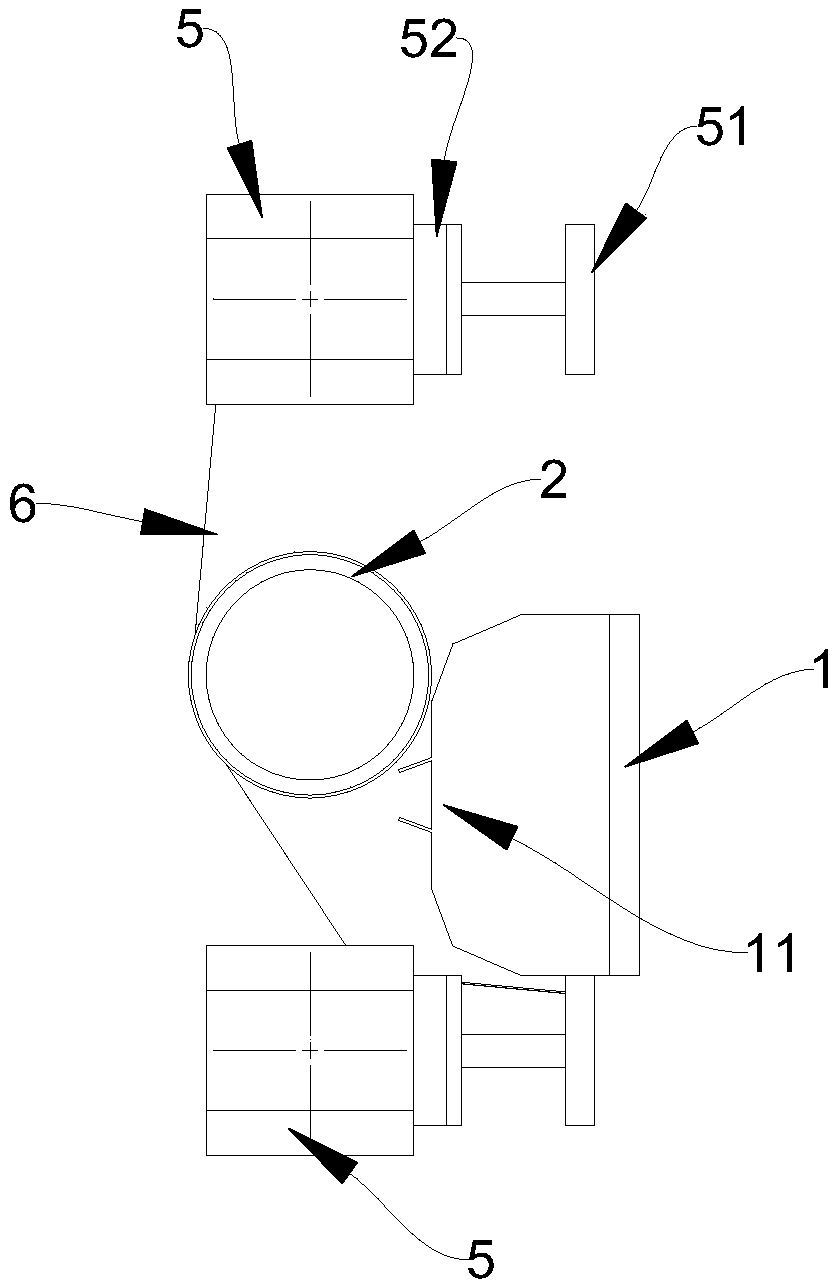

[0022] Wherein, the coating tank 1 is used to contain the slurry to be coated, and the coating tank 1 is provided with a strip discharge port 11, such as Figure 4 shown.

[0023] The coating roller 2 can rotate, and the coating roller 2 is arranged corresponding to the discharge port 11 of the coating tank 1, and the radial direction of the coating roller 2 is consistent with the strip direction of the discharge port 11.

[0024] Adhesive Tape 3 The adhesive tape 3 is arranged on the paint tank 1 , and the adhesive tape 3 can cover part of the discharge port 11 . The thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com