Combined leaching-stabilization rehabilitation method for soil contaminated by chromium residue

A technology of combined restoration of polluted soil, which is applied in the field of soil pollution treatment, can solve problems such as the difficulty in achieving the time required for the reaction between the reducing agent and soil hexavalent chromium, incomplete reduction of hexavalent chromium, and the increase in the amount of reducing agent used to solve the problem of soil pollution. Severe matrix loss, reduced leaching water consumption, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

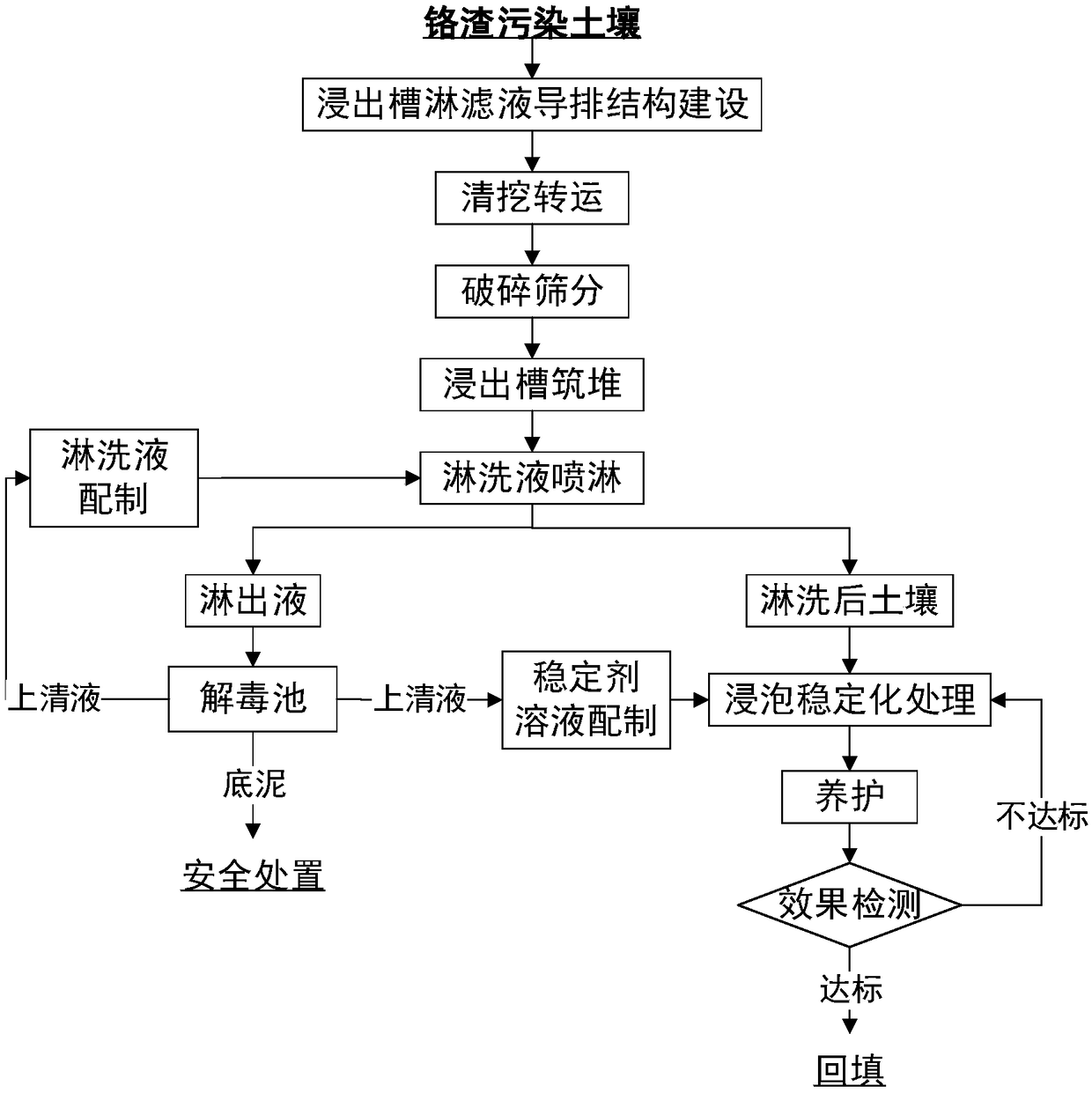

[0032] like figure 1 Shown:

[0033] (1) Restoration preparation: Excavation and transfer of chromium slag-contaminated soil, crushing and screening, construction of leachate drainage structure, soil heaping, etc. The concentration of hexavalent chromium in the soil sample selected in this embodiment is 5670.3 mg / kg, and the content of hexavalent chromium in the leachate is 122.7 mg / L. This embodiment is carried out in a 1000L beef tendon vat. The size of the beef tendon vat is 140 cm in diameter and 75 cm in height. There is a discharge port at the bottom, and the discharge of the leachate is controlled by a switch. Firstly, gravel is laid on the bottom of the vat to form a leachate drainage structure, and the thickness of the gravel layer is 15cm. The soil is piled on top of the crushed stone layer, naturally accumulated, with a thickness of 55cm.

[0034] (2) Rinse repair: After the repair preparation process is completed, prepare a eluent consisting of 7 parts by mass o...

Embodiment 2

[0037] like figure 1 Shown:

[0038] (1) Restoration preparation: Excavation and transfer of chromium slag-contaminated soil, crushing and screening, construction of leachate drainage structure, soil heaping, etc. The concentration of hexavalent chromium in the soil sample selected in this embodiment is 3244.2 mg / kg, and the content of hexavalent chromium in the leachate is 126.4 mg / L. This embodiment is carried out in a 1000L beef tendon vat. The size of the beef tendon vat is 140 cm in diameter and 75 cm in height. There is a discharge port at the bottom, and the discharge of the leachate is controlled by a switch. Firstly, gravel is laid on the bottom of the vat to form a leachate drainage structure, and the thickness of the gravel layer is 15cm. The soil is piled on top of the crushed stone layer, naturally accumulated, with a thickness of 55cm.

[0039] (2) Rinse repair: After the repair preparation process is completed, prepare a eluent consisting of 5 parts of GLDA, ...

Embodiment 3

[0042] like figure 1 Shown:

[0043] (1) Restoration preparation: Excavation and transfer of chromium slag-contaminated soil, crushing and screening, construction of leachate drainage structure, soil heaping, etc. The concentration of hexavalent chromium in the soil sample selected in this embodiment is 4340.2 mg / kg, and the content of hexavalent chromium in the leachate is 86.4 mg / L. This embodiment is carried out in a 1000L beef tendon vat. The size of the beef tendon vat is 140 cm in diameter and 75 cm in height. There is a discharge port at the bottom, and the discharge of the leachate is controlled by a switch. Firstly, gravel is laid on the bottom of the vat to form a leachate drainage structure, and the thickness of the gravel layer is 15cm. The soil is piled on top of the crushed stone layer, naturally accumulated, with a thickness of 55cm.

[0044] (2) Rinse repair: After the repair preparation process is completed, prepare a eluent consisting of 6 parts of GLDA, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com