Chromium pollution soil in-situ leaching treatment method

A technology for chromium-contaminated soil and a treatment method, which is applied in the field of in-situ leaching treatment of chromium-contaminated soil, can solve the problems of long construction period, need for engineering ground breaking, high energy consumption and cost, and achieves low power consumption, low treatment cost, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

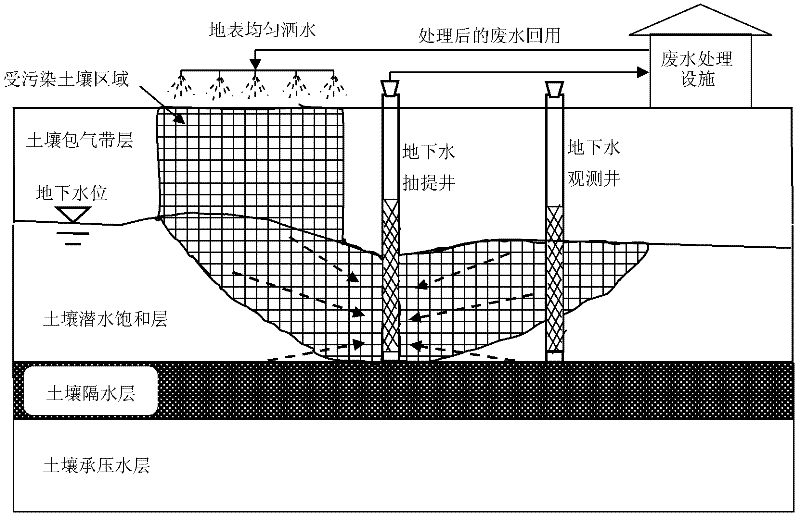

Method used

Image

Examples

Embodiment 1

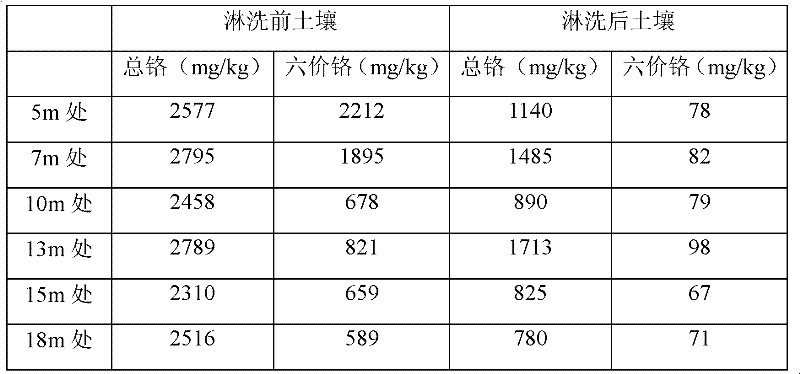

[0028] Take the treatment of chromium-contaminated workshops left over from Haibei Chromium Salt Chemical Plant in Qinghai as an example. The chemical plant was put into operation in 1988 and was forced to close in 1989 due to serious pollution. The plant's leaching workshop (plant area 150m×40m) is seriously polluted, and the soil from the surface to the underground water table (18 meters deep) is seriously polluted. Among them, the concentration of hexavalent chromium in the soil of 0-3 meters in the surface layer is between 3000-14000mg / kg, and the concentration of hexavalent chromium in the soil of 3-18 meters is about 2000mg / kg. The soil structure of the site is simple, with no missing layers, water-repellent layers, and no short-flow channels. The soil 0-3 meters is loess-like soil, the permeability coefficient is 2.5×10 -3 cm / s, below 3 meters to the groundwater level is a gravel layer, with a permeability coefficient of 0.243cm / s, which is suitable for the technical ...

Embodiment 2

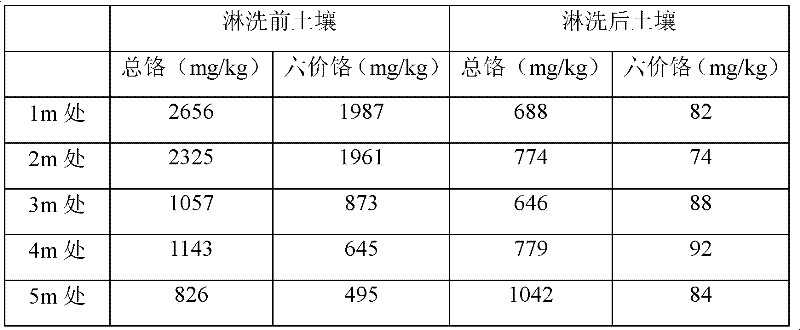

[0039] Take the treatment of contaminated soil at the chromium slag dump site of Qingdao Hongxing Chemical Plant as an example. The plant was put into production in 1959, and the production of chromium salts was stopped in 1991 due to environmental protection issues. The original chromium slag storage yard is located by the Loushan River, covering an area of about 600m×200m. Due to the accumulation of chromium slag for many years, the site was seriously polluted by chromium. Among them, the concentration of hexavalent chromium in the surface soil reaches 142-9759mg / kg, and the concentration of hexavalent chromium in the groundwater of the site reaches 200mg / L, far exceeding the requirement of 0.05mg / L required by the third-class water quality standard for groundwater. The strongly weathered granite layer in the whole area is mainly composed of three layers of miscellaneous fill, silty clay and coarse sand.

[0040] Proceed as follows:

[0041] 1) A 6m×4m×1m pit was dug in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com