Improved welding head fixing device

A welding head and fixing device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as affecting the normal use of the ball screw, dislocation of the welding head of the welding head, and generating more sparks, etc. To achieve the effect of tight fixed connection, avoid dislocation, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

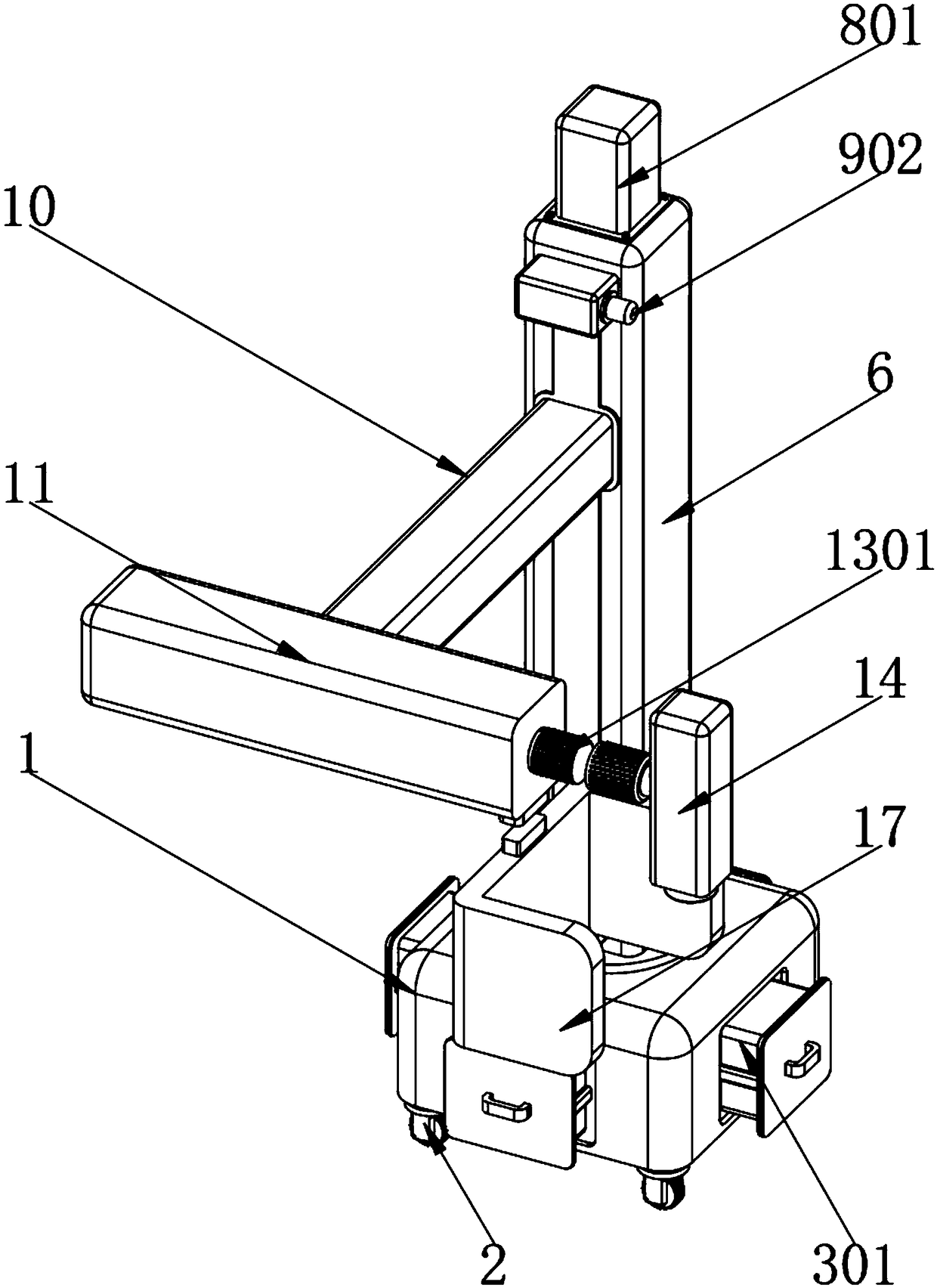

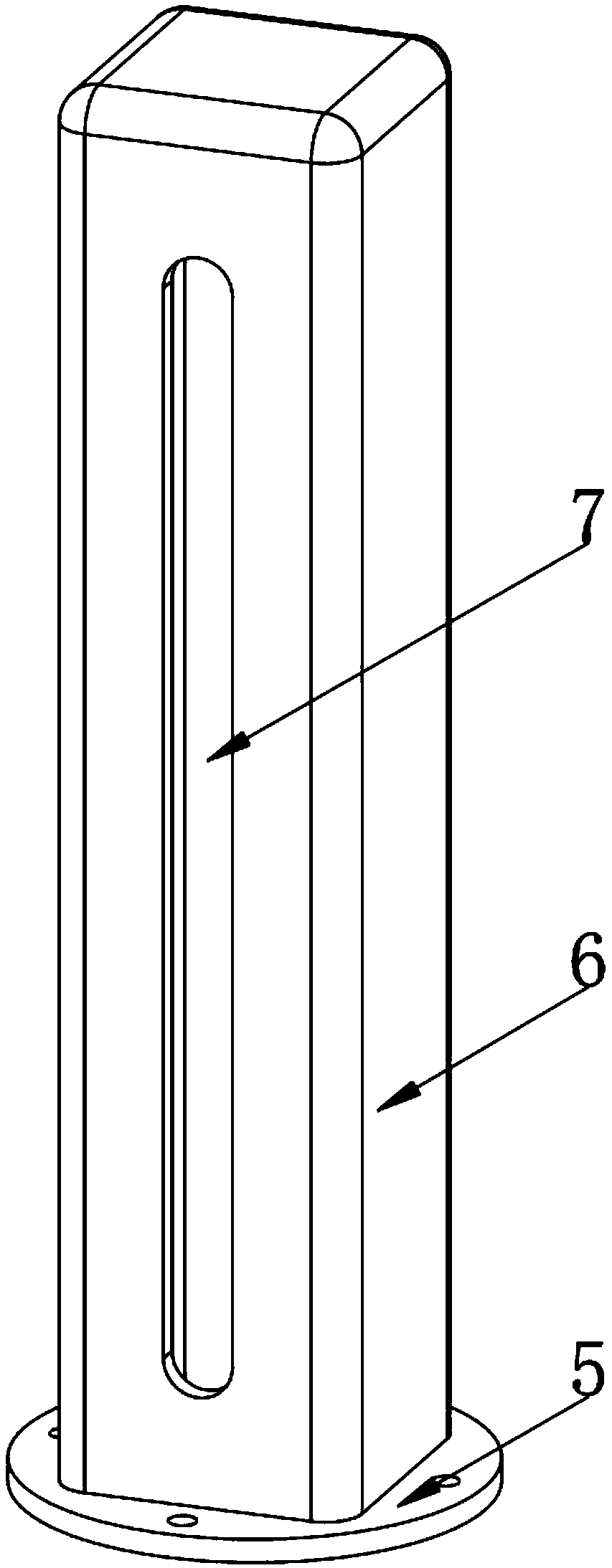

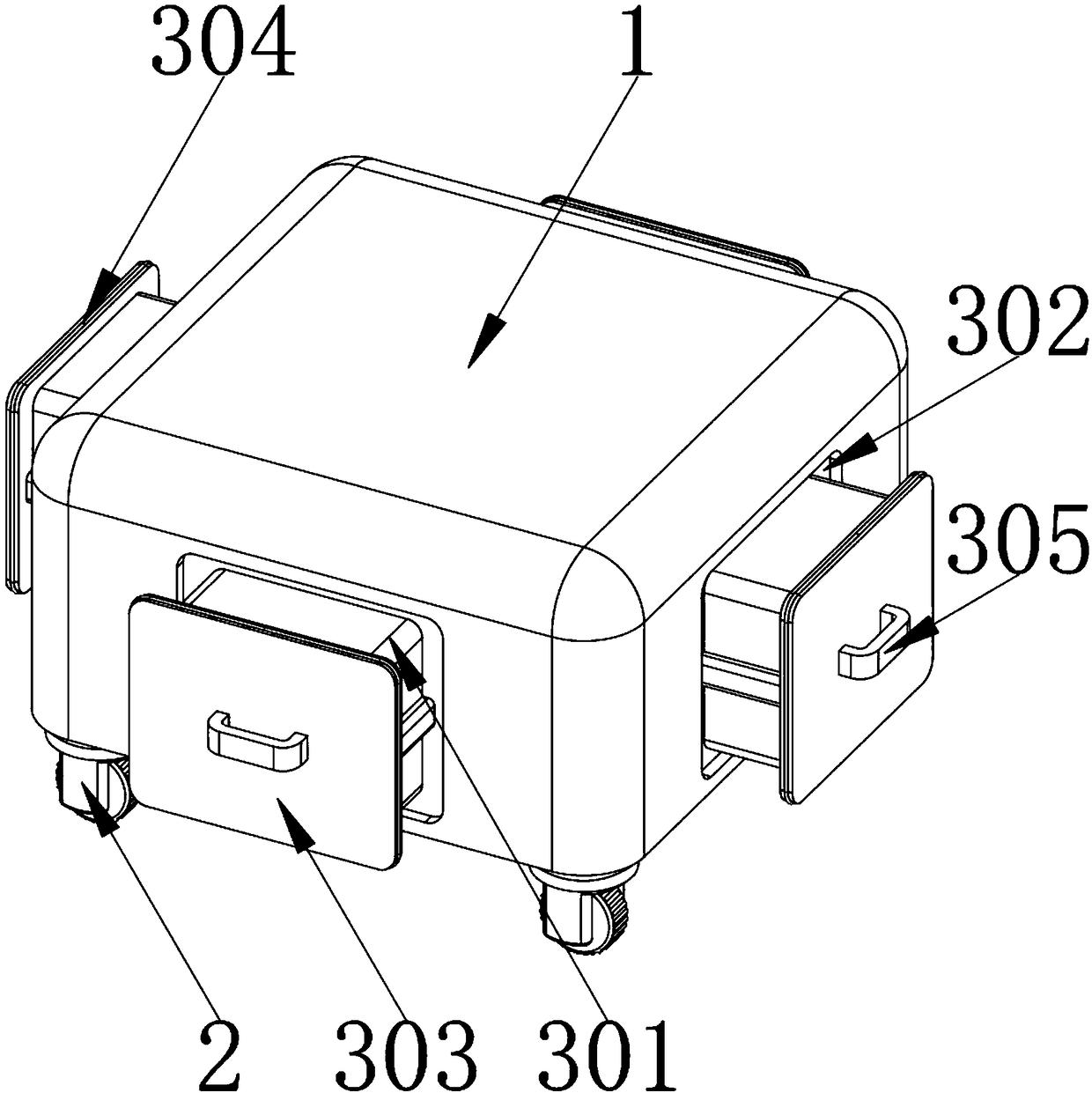

[0048] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, an improved welding head fixing device, including a base 1, and the corners of the bottom of the base 1 are fixed with universal wheels 2 by fixing screws, and each side of the base 1 A counterweight assembly 3 is installed inside, and the counterweight assembly 3 includes a counterweight 301 , an installation slot 302 , an installation card 303 , a fixed rubber ring 304 and a disassembly handle 305 ;

[0049] Each side of the base 1 is embedded with a counterweight 301, and the middle of each side of the base 1 is provided with a mounting slot 302. One end of the counterweight 301 is fixed with a mounting card 303 by a fixing screw, and the side of the mounting card 303 A fixed rubber ring 304 is embedded in the upper part by glue, and a disassembly handle 305 is fixed in the middle of one side of the installation clamp 303 by fixing screws. In order to make the installation cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com