A design method of anti-sway bilge keel

A design method, the technology of the bilge keel, applied in the field of anti-rolling bilge keel design, can solve the problems of increased space and weight of equipment on board, increased ship design and construction costs, unsatisfactory anti-rolling effect, etc., to achieve reduction Occupies space and weight, reduces design and construction costs, and has the best anti-rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] The design method of the anti-rolling bilge keel of the first preferred embodiment, including:

[0046] Step S1: Determine the length L of the bilge keel according to the main dimension parameters of the target ship type and the characteristics of the hull shape BK and the layout range of the bilge keel along the ship's length direction (X-axis direction) [X start , X end ];

[0047] Step S2.1: Provide a cross-section diagram of the maximum cross-section of the target ship type, the cross-section diagram takes the direction of the ship's length as the direction of the abscissa axis (X-axis direction), and takes the direction of the ship's width as the direction of the ordinate-axis direction (Y-axis direction) ;

[0048] Step S2.2: Draw the frame angle of the maximum cross-section bounding box formed by the intersection of the bottom baseline or bilge rise line and the ship width margin line on the cross-section line diagram;

[0049] Step S2.3: Draw the height Z of t...

no. 2 example

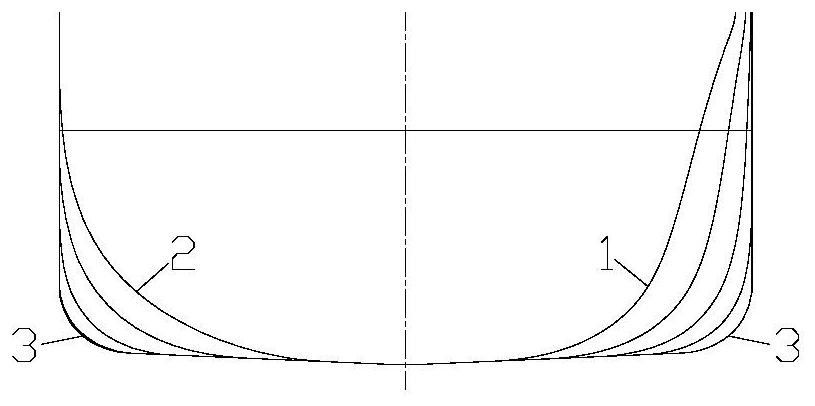

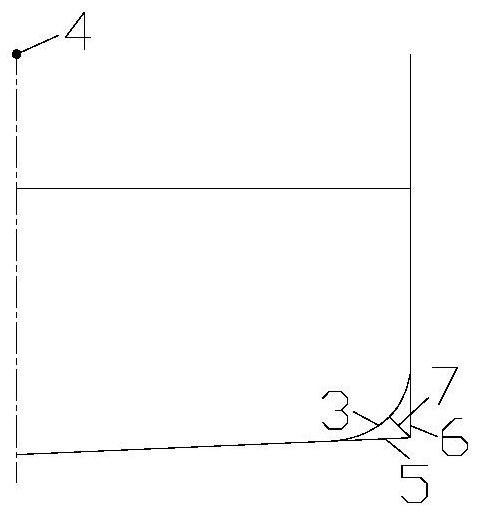

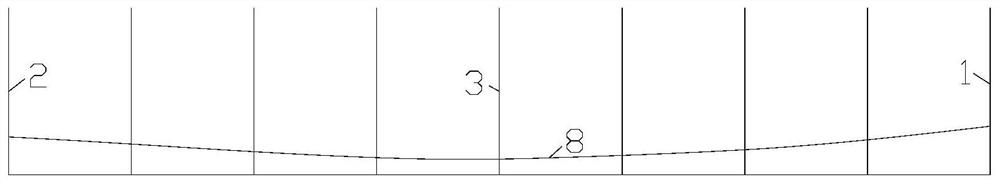

[0070] figure 1 It is the cross-sectional line diagram of the hull substations within the scope of the arrangement of the bilge keel along the length of the ship in the design method of the anti-rolling bilge keel of the present invention, figure 2 It is a schematic diagram of the maximum allowable width of the shape of the bilge keel at the maximum cross section of the anti-rolling bilge keel design method of the present invention, image 3 It is a side projection diagram of the installation line of the bilge keel on the hull of the design method of the anti-rolling bilge keel of the present invention, Figure 4 It is a schematic diagram of the maximum allowable width of the shape of the bilge keel at the transverse section line of a certain substation of the design method of the anti-rolling bilge keel of the present invention, Figure 5 It is a schematic diagram of the maximum allowable width limit line of the bilge keel shape and the maximum width limit line of the bilge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com