Prediction method for bimetal composite material strength

A composite material and prediction method technology, applied in the direction of analyzing materials, strength characteristics, measuring devices, etc., can solve problems such as the inability to accurately reflect the true strength, the deviation between the predicted value and the test value of the strength of bimetal composite materials, and reduce the Test volume, wide applicability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention provides a method for predicting the strength of a bimetallic composite material, comprising the steps of:

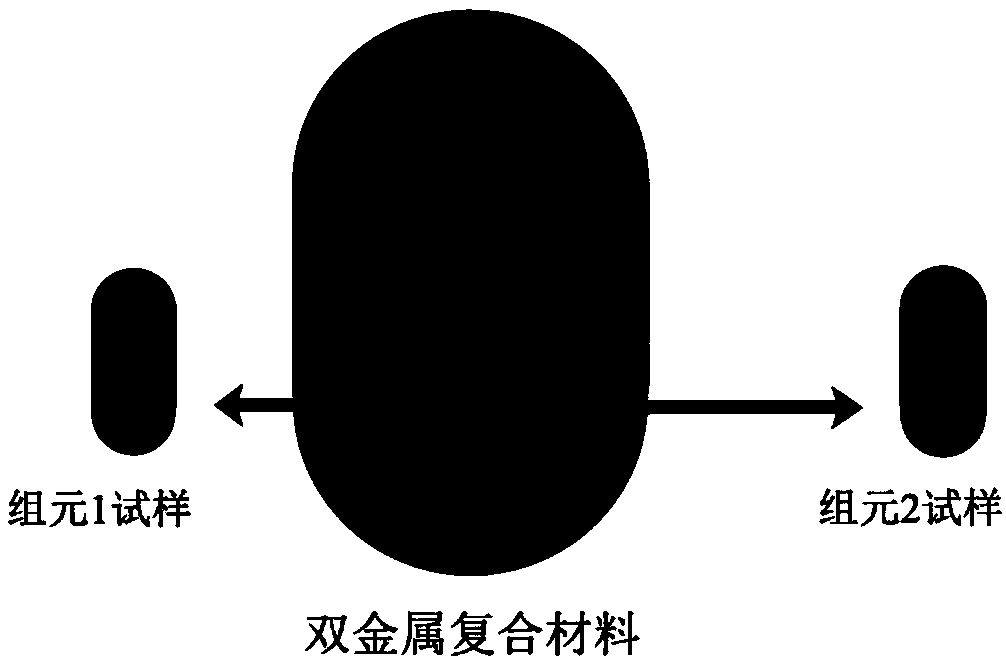

[0021] (1) Use wire cutting to directly cut a magnesium component bar sample with a diameter of 6mm and an aluminum component bar sample with a diameter of 5mm from a Mg / Al composite bar (20mm in diameter, of which the aluminum core diameter is 6mm). For mechanical performance testing, the schematic diagram of sample cutting is as follows: figure 1 shown;

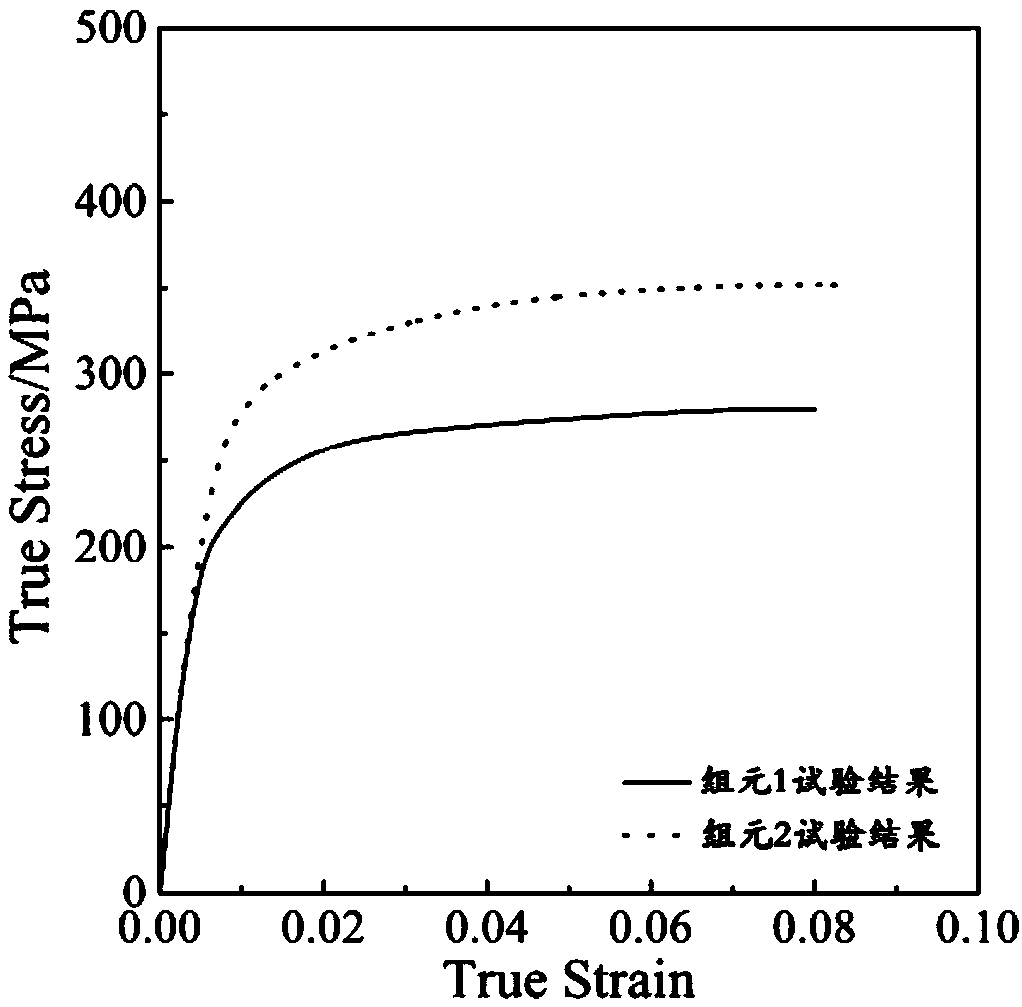

[0022] (2) Test the mechanical properties of the magnesium component and aluminum component samples cut in step (1) respectively, and obtain the stress-strain curve and strength σ of the magnesium component and aluminum component 1 , σ 2 , please refer to the stress-strain curve of the two components figure 2 ;

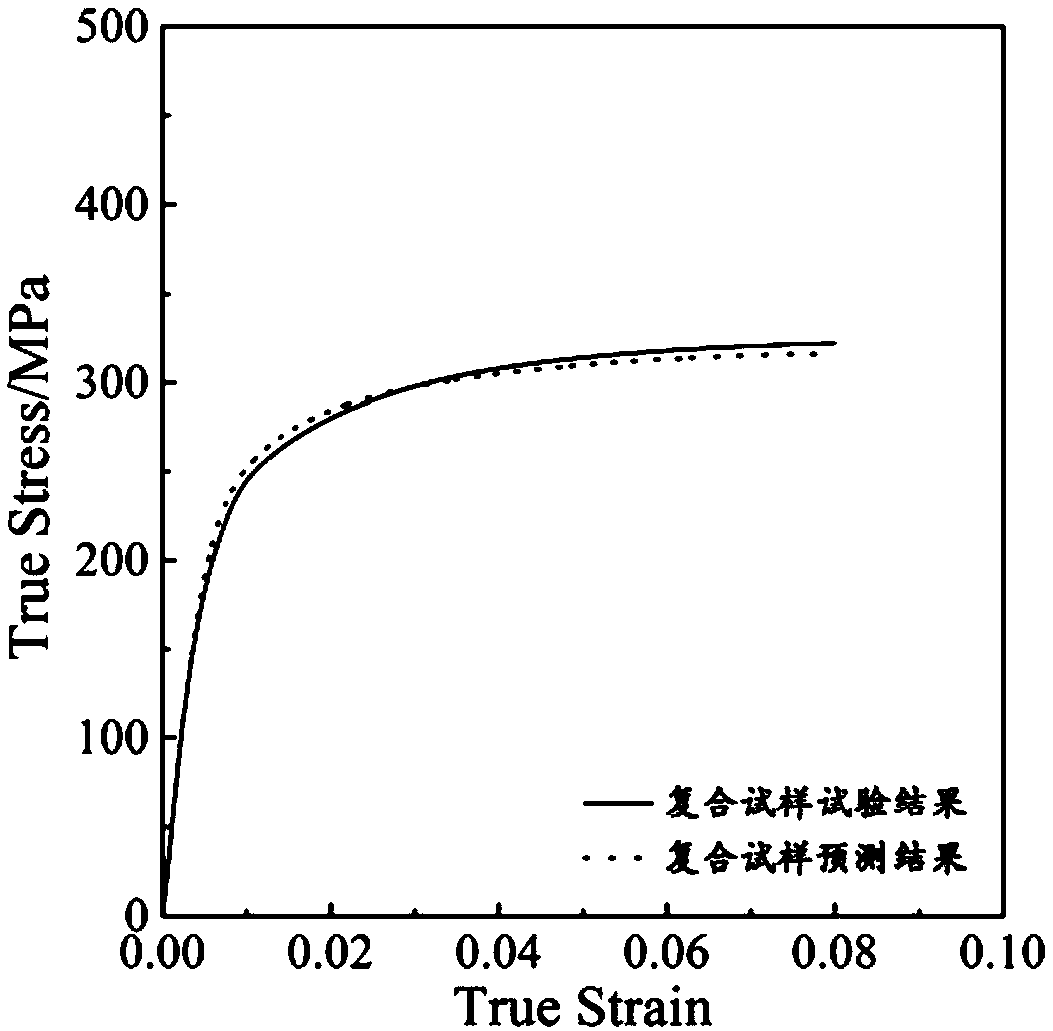

[0023] (3) Carry out SEM test analysis to the Mg / Al composite sample in step (1), obtain the volume fraction V that the magnesium component and the aluminum component occupy in the ...

Embodiment 2

[0026] The invention provides a method for predicting the strength of a bimetallic composite material, comprising the steps of:

[0027] (1) Use wire cutting to directly cut aluminum components with a diameter of 5 mm and copper components with a diameter of 5 mm from the Al / Cu composite rod (18 mm in diameter, with a copper core diameter of 6 mm) for mechanical performance testing ;

[0028] (2) Test the mechanical properties of the aluminum component and copper component samples cut in step (1) respectively, and obtain the stress-strain curve and strength σ of the aluminum component and copper component 1 , σ 2 ;

[0029] (3) carry out SEM test analysis to the Al / Cu composite sample in step (1), obtain the volume fraction V that aluminum component and copper component occupy in Al / Cu composite sample 1 and V 2 ;

[0030] (4) Substitute the strength and volume fraction of aluminum and copper components obtained in step (2) and step (3) into the mixing law formula σ c = ...

Embodiment 3

[0032] The invention provides a method for predicting the strength of a bimetallic composite material, comprising the steps of:

[0033] (1) Use wire cutting to directly cut aluminum components with a width of 10mm and a thickness of 5mm from the Al / Steel composite plate (the width and thickness are 30mm and 15mm, respectively, and the width and thickness of the aluminum layer are 30mm and 8mm). Steel component samples with a thickness of 10mm and a thickness of 5mm are used for mechanical performance testing;

[0034] (2) Test the mechanical properties of the aluminum component and steel component samples cut in step (1) respectively, and obtain the stress-strain curve and strength σ of the aluminum component and steel component 1 , σ 2 ;

[0035] (3) The Al / Steel composite sample in step (1) is carried out SEM test analysis, obtains the volume fraction V that the aluminum component and the steel component occupy in the Al / Steel composite sample 1 and V 2 ;

[0036] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com