Gun barrel strength testing device

A technology of strength testing and gun barrel, which is applied in production, civilian gun research, testing, and military fields. It can solve problems such as threatening the personal safety of testers, high chamber pressure at the moment of firing, and bursting of the main body of the receiver. It is simple, reliable, and easy to test. Improved safety and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following describes the patent of the present invention in detail with reference to the drawings. The following embodiments may enable those skilled in the art to better understand the patent of the present invention, but do not limit the patent of the present invention in any form.

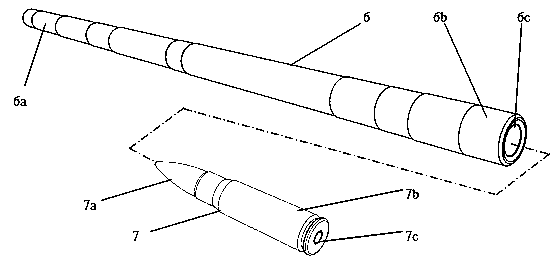

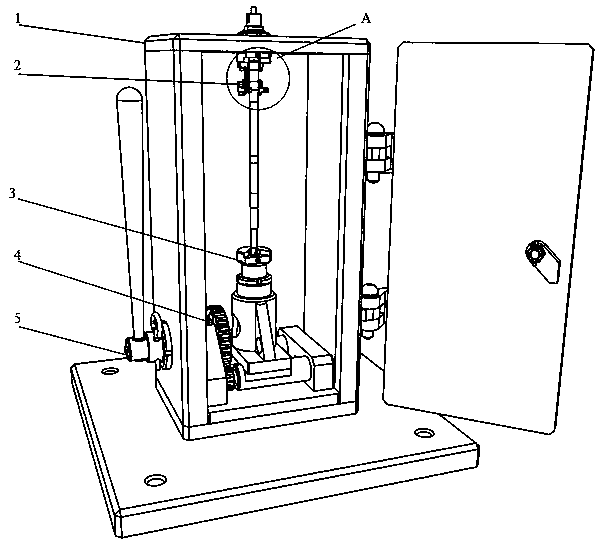

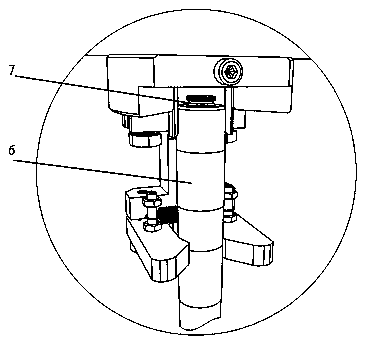

[0064] Such as figure 1 Shown is a schematic diagram of the barrel and bullet structure. Figure 2-38 As shown, it is a method for testing such as figure 1 The strength test device of the barrel shown is composed of a box assembly 1, a firing assembly 2, a base assembly 3, a locking assembly 4 and a driving rod assembly 5. The box body assembly 1 is composed of a box body 11 and a door panel 12. The box body 11 is five sides of a cube. The door panel 12 is hinged on the open side of the box body 11 to form a closed cube. The top of the box body 11 is machined with a firing mechanism installation hole 11a. , Used to install the firing assembly 2; the lower left side is machined with a drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com