Blisk or blade molded surface ultrasonic strengthening method

An ultrasonic strengthening, integral blisk technology, applied in the field of finishing, can solve problems such as high requirements for strengthening equipment of large structural parts, deformation of thin parts, and affected effects, so as to improve surface integrity, improve fatigue strength, and improve application Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

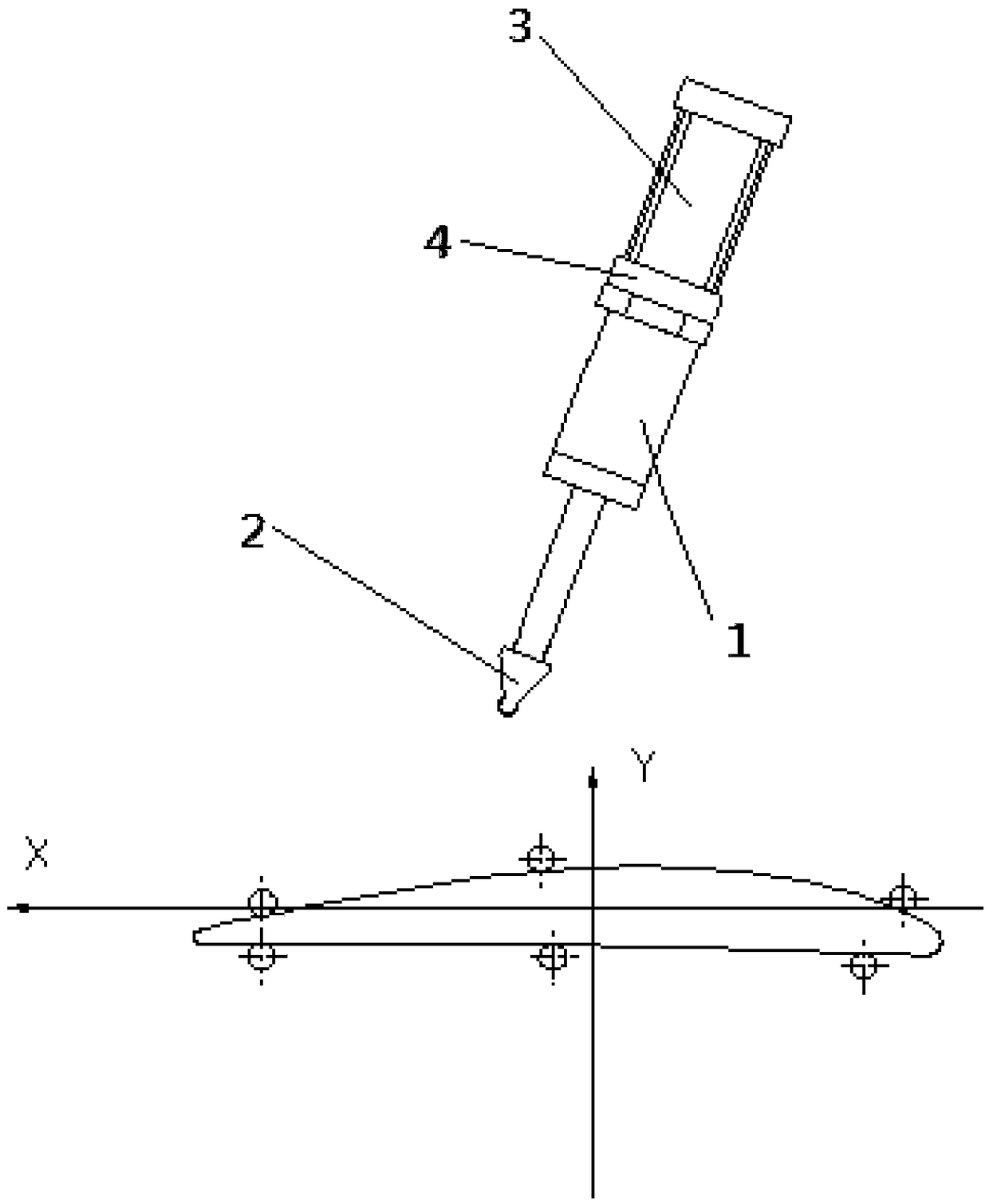

[0025] like figure 1 As shown, in this embodiment, a five-axis linkage machining center is preferably used, and the ultrasonic impact device is fixed to the HSK handle 3 and connected to the main shaft.

[0026] The ultrasonic impact device includes a tool head 2 and a vibration generator 1. The tool head 2 is used for processing in contact with the workpiece; the vibration generator 1 is externally connected to the power switch of the host machine of the ultrasonic impact device, and an oil return nozzle and an oil inlet nozzle are arranged inside to pass through the lubricating oil. , to achieve lubrication on the surface of the workpiece.

[0027] The end of the vibration generator 1 is fixed and coaxially connected with the HSK handle 3 through the taper sleeve 4 and the locknut.

[0028] The specific operation steps are as follows:

[0029] Step 1: Install the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com