Formula of high-elongation super-tough nylon 56 and preparation method thereof

A high-elongation, super-tough technology, applied in the formulation and preparation of high-elongation super-tough nylon 56, can solve the problems of inability to have toughness and ductility, dependence, low elongation of nylon 56, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention provides a technical solution: a formula of high-elongation super-tough nylon 56, including 70.5% of PA56 resin, 0.2% of coupling agent KH550, 28% of toughening agent, 0.5% of lubricant, 0.3 % mold release agent, 0.5% antioxidant.

[0021] Preferably, the viscosity of the PA56 resin is 2.7.

[0022] Preferably, the toughening agent is maleic anhydride grafted ethylene octene copolymer.

[0023] Preferably, the antioxidant is a mixture of antioxidant 1098 and antioxidant 168 in a ratio of 2:1.

[0024] Preferably, the lubricant is N,N'-ethylene bisstearamide, and the release agent is high molecular weight polyethylene sodium.

[0025] Preferably, the release agent is high molecular weight polyethylene sodium.

[0026] Preferably, the glass fiber is a glass fiber with a monofilament diameter of 13.5µ.

Embodiment 2

[0028] The invention provides a technical solution: a formula of high-elongation super-tough nylon 56, including 76% of PA56 resin, 0.2% of coupling agent KH550, 23.2% of toughening agent, 0.2% of lubricant, 0.1 % release agent, 0.3% antioxidant.

[0029] Preferably, the viscosity of the PA56 resin is 2.7.

[0030] Preferably, the toughening agent is ethylene-propylene-diene rubber grafted with maleic anhydride.

[0031] Preferably, the antioxidant is a mixture of antioxidant 1098 and antioxidant 168 in a ratio of 2:1.

[0032] Preferably, the lubricant is N,N'-ethylene bisstearamide, and the release agent is high molecular weight polyethylene sodium.

[0033] Preferably, the release agent is high molecular weight polyethylene sodium.

[0034] Preferably, the glass fiber is a glass fiber with a monofilament diameter of 13.5µ.

Embodiment 3

[0036] The invention provides a technical solution: a formula of high-elongation super-tough nylon 56, including 72% of PA56 resin, 0.4% of coupling agent KH550, 27.6% of toughening agent, 0.4% of lubricant, 0.2% % mold release agent, 0.4% antioxidant.

[0037] Preferably, the viscosity of the PA56 resin is 2.7.

[0038] Preferably, the toughening agent is maleic anhydride grafted ethylene octene copolymer.

[0039] Preferably, the antioxidant is a mixture of antioxidant 1098 and antioxidant 168 in a ratio of 2:1.

[0040] Preferably, the lubricant is N,N'-ethylene bisstearamide, and the release agent is high molecular weight polyethylene sodium.

[0041] Preferably, the release agent is high molecular weight polyethylene sodium.

[0042] Preferably, the glass fiber is a glass fiber with a monofilament diameter of 13.5µ.

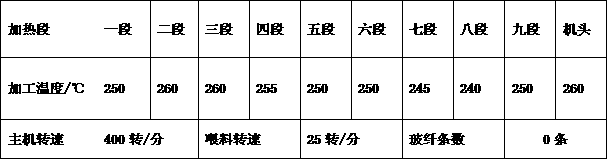

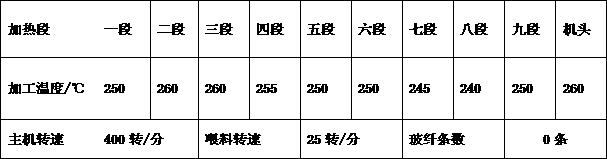

[0043] A kind of preparation method of high elongation ultra-tough nylon 56 is characterized in that, comprises the following steps:

[0044] Step 1. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com