Liquid crystal aligning agent for photo alignment, liquid crystal aligning film, and liquid crystal display device

A technology of liquid crystal alignment agent and photo-orientation, which is applied in liquid crystal materials, optics, nonlinear optics, etc., can solve the problems of liquid crystal alignment film or the reduction of afterimage characteristics, and achieve the effect of high liquid crystal orientation and afterimage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0175] Hereinafter, the present invention will be described through examples. In addition, the evaluation methods and compounds used in the examples are as follows.

[0176]

[0177] 1. Weight average molecular weight (Mw)

[0178] The weight average molecular weight of a polyamic acid is calculated|required by the GPC method using 2695 separation modules and 2414 differential refractometers (made by Waters), and it calculated|required in polystyrene conversion. Dilute the obtained polyamic acid with a phosphoric acid-dimethylformamide (Dimethylformamide, DMF) mixed solution (phosphoric acid / DMF=0.6 / 100: weight ratio) so that the polyamic acid concentration becomes about 2% by weight . HSPgel RT MB-M (manufactured by Waters) was used as a column, and the mixed solution was used as a developing solvent, and the measurement was performed at a column temperature of 50° C. and a flow rate of 0.40 mL / min. As the standard polystyrene, TSK standard polystyrene manufactured by To...

Synthetic example 1

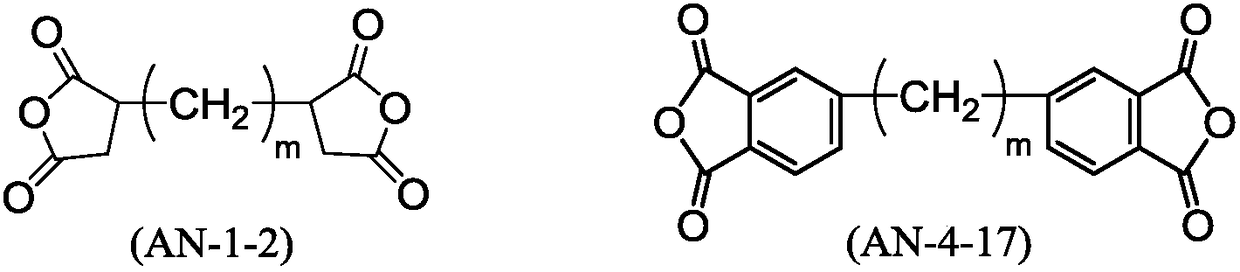

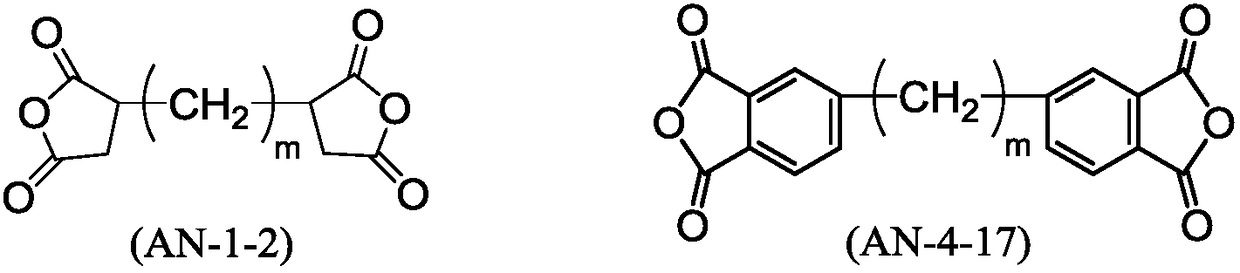

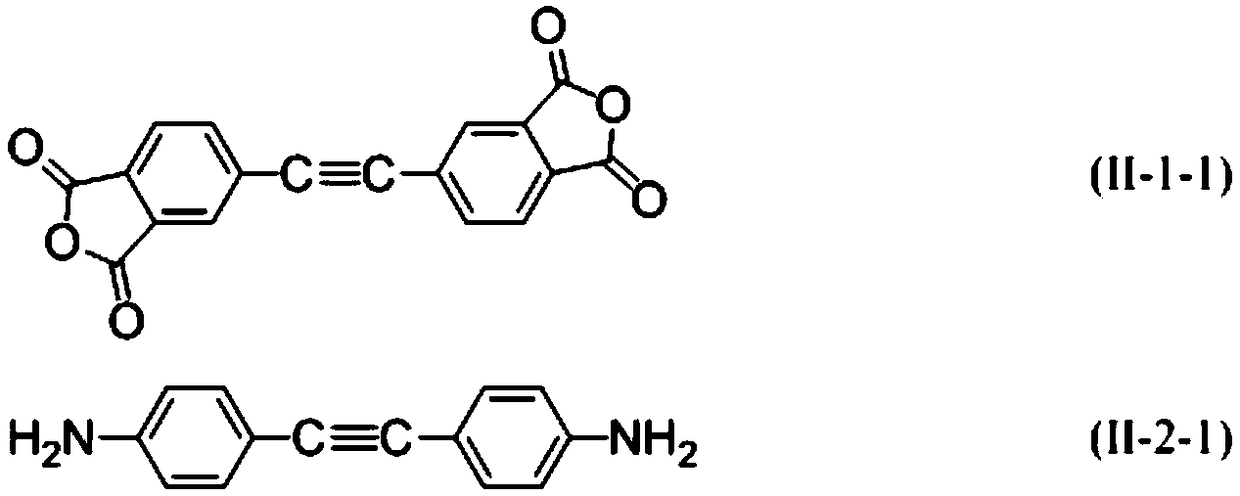

[0196] Put into the compound represented by the formula (V-2-1) of 2.1218g, 0.2087g of the formula (DI-13-1 ), 0.0851 g of the compound represented by the formula (DI-4-13), and 54.0 g of dehydrated NMP were stirred and dissolved under a dry nitrogen stream. Then, put the compound represented by the formula (AN-4-17) (m=8) of 2.7086g, the compound represented by the formula (PA-1) of 0.4357g, the compound represented by the formula (AN-1-1) of 0.4401g The indicated compound was mixed with 10.0 g of dehydrated NMP and stirring was continued at room temperature for 24 hours. BC 30.0g was added to the said reaction solution, and it stirred, heating to 60 degreeC, until the Mw of a polymer became a desired value, and the polyamic-acid solution whose polymer solid content concentration was 6 weight% was obtained. Let the said polyamic-acid solution be varnish A1. The Mw of the polymer A1 contained in the varnish A1 was 13,260. In addition, the varnish A1 was fractionated into a ...

Embodiment 1

[0203] [Example 1] Preparation of liquid crystal alignment agent for photo-alignment, fabrication of fringe field switching (Fringe Field Switching, FFS) liquid crystal display element and measurement of AC afterimage

[0204] Weigh 4.0 g of varnish A1 and 6.0 g of varnish B1 in a 50 mL eggplant-shaped flask, and add 5.0 g of N-methyl-2-pyrrolidone and 5.0 g of butyl cellosolve therein, and stir at room temperature for 1 hour. Thereby, the liquid crystal aligning agent 1 for photo-alignment with a resin component density|concentration of 3 weight% was obtained. In addition, 1 fraction of the prepared liquid crystal aligning agent for photoalignment was taken into a brown bottle, and it was stored at room temperature for 7 days. Let the stored liquid crystal aligning agent for photo-alignment be the liquid crystal aligning agent 1' for photo-alignment. When the viscosity of the liquid crystal aligning agent 1 for photo-alignment and the liquid crystal aligning agent 1' for pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com