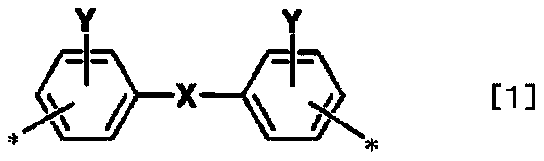

Liquid crystal aligning agent, liquid crystal alignment film, manufacturing method of liquid crystal alignment film, and liquid crystal display element

A liquid crystal aligning agent and solvent technology, which is used in liquid crystal materials, chemical instruments and methods, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0224] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to these examples.

[0225] (specific diamine)

[0226] W-A1: Compound represented by formula [W-A1], W-A2: Compound represented by formula [W-A2]

[0227] W-A3: Compound represented by formula [W-A3]

[0228] (Other side chain diamine compounds)

[0229] A1: Compound represented by formula [A1]

[0230]

[0231] C1: Compound represented by formula [C1], C2: Compound represented by formula [C2]

[0232] C3: Compound represented by formula [C3]

[0233]

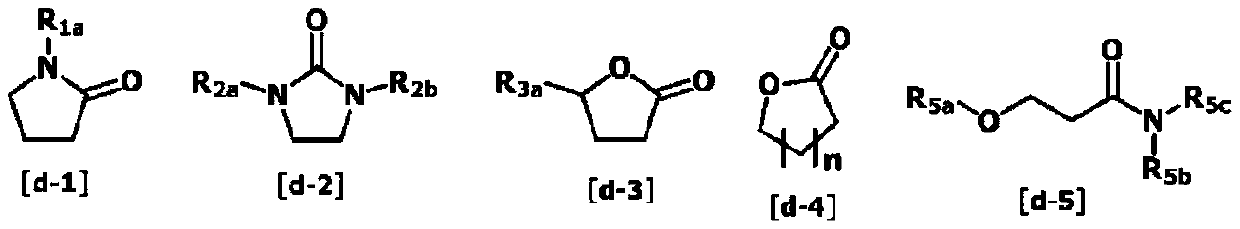

[0234] (tetracarboxylic acid compound)

[0235] D1: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0236] D2: Bicyclo[3,3,0]octane-2,4,6,8-tetracarboxylic dianhydride

[0237] D3: pyromellitic dianhydride

[0238]

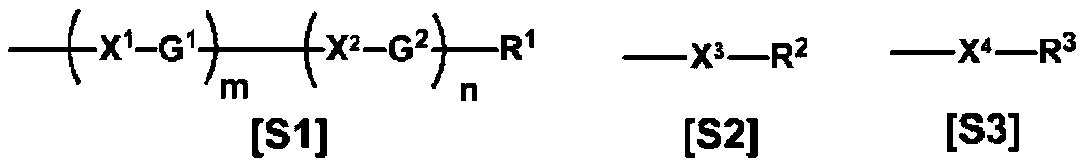

[0239] (solvent)

[0240] NEP: N-ethyl-2-pyrrolidone, GVL: γ-valerolactone,

[0241] GBL: γ-butyrolactone NMP: N-methyl-2-pyrrolidone,

[0242] CHP: N-cyclohexy...

Synthetic example 1W-A1

[0271]

[0272]

[0273]

[0274] In a reaction vessel, 4,4'-dinitro-1,1'-biphenyl-2,2'-dimethanol (41.1 g, 135 mmol) and triethylamine (31.5 g ), and methanesulfonyl chloride (33.2 g) was added dropwise under ice-cooling under a nitrogen atmosphere, and reacted for 1 hour to obtain compound [1]. Next, p-(trans-4-heptylcyclohexyl)phenol (77.8 g) dissolved in tetrahydrofuran (246.6 g) was added, stirred at 40°C for 1 hour, and then added in pure water (233 g) at the same temperature. ) of potassium hydroxide (41.0 g) was allowed to react for 21 hours. After completion of the reaction, a 1.0M hydrochloric acid aqueous solution (311 ml) and pure water (1050 g) were added to precipitate a crude product, which was collected by filtration. The obtained crude product was heated and dissolved in tetrahydrofuran (574 g) at 50° C., methanol (328 g) was added to precipitate crystals, and compound [2] was obtained by filtering and drying (yield: 97.9 g, yield: 89%).

[0275] 1 H...

Synthetic example 2W-A2

[0279]

[0280]

[0281]

[0282] Tetrahydrofuran (327.2 g), 4,4'-dinitro-2,2'-biphenyl acid (40.9 g, 123 mmol) and p-(trans-4-heptylcyclohexyl)phenol ( 72.1g), 4-dimethylaminopyridine (1.50g), drop into 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (56.6g ), allowing it to react for 3 hours. After completion of the reaction, the reaction solution was poured into pure water (1226 g) to deposit a crude product, which was collected by filtration. Next, after slurry-washing the crude product with methanol (245g), it filtered, and the obtained crude product was heated and melt|dissolved in tetrahydrofuran (245g) at 60 degreeC. After removing the insoluble matter by filtration, after concentration under reduced pressure to make the internal total weight 232g, methanol (163g) was added to precipitate crystals, and after stirring under ice-cooling conditions, filtration and drying were carried out to obtain compound [3] (yield: 73.9 g, yield: 71%).

[0283] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com