Heat-resistant die-casting aluminum alloy and preparation method thereof

A casting aluminum alloy and heat-resistant technology, which is applied in the field of aluminum alloys, can solve the problems of low-temperature mechanical properties of aluminum alloys, stress concentration, splitting the matrix, etc., and achieve the effects of improving thermal stability and reducing the degree of lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A high-strength and high-thermal-conductivity thin-walled die-cast aluminum alloy, including the components described in the following Table 1 by weight percentage, with the balance being aluminum and unavoidable impurities.

[0026] Ce: 0.5wt%-3wt%; B <0.05wt%; Fe: 0.5wt%-3wt%; Sc <0.5wt%; Cu <0.5wt%, other unavoidable impurities are controlled below 0.05wt%, and the balance is Al and unavoidable impurities.

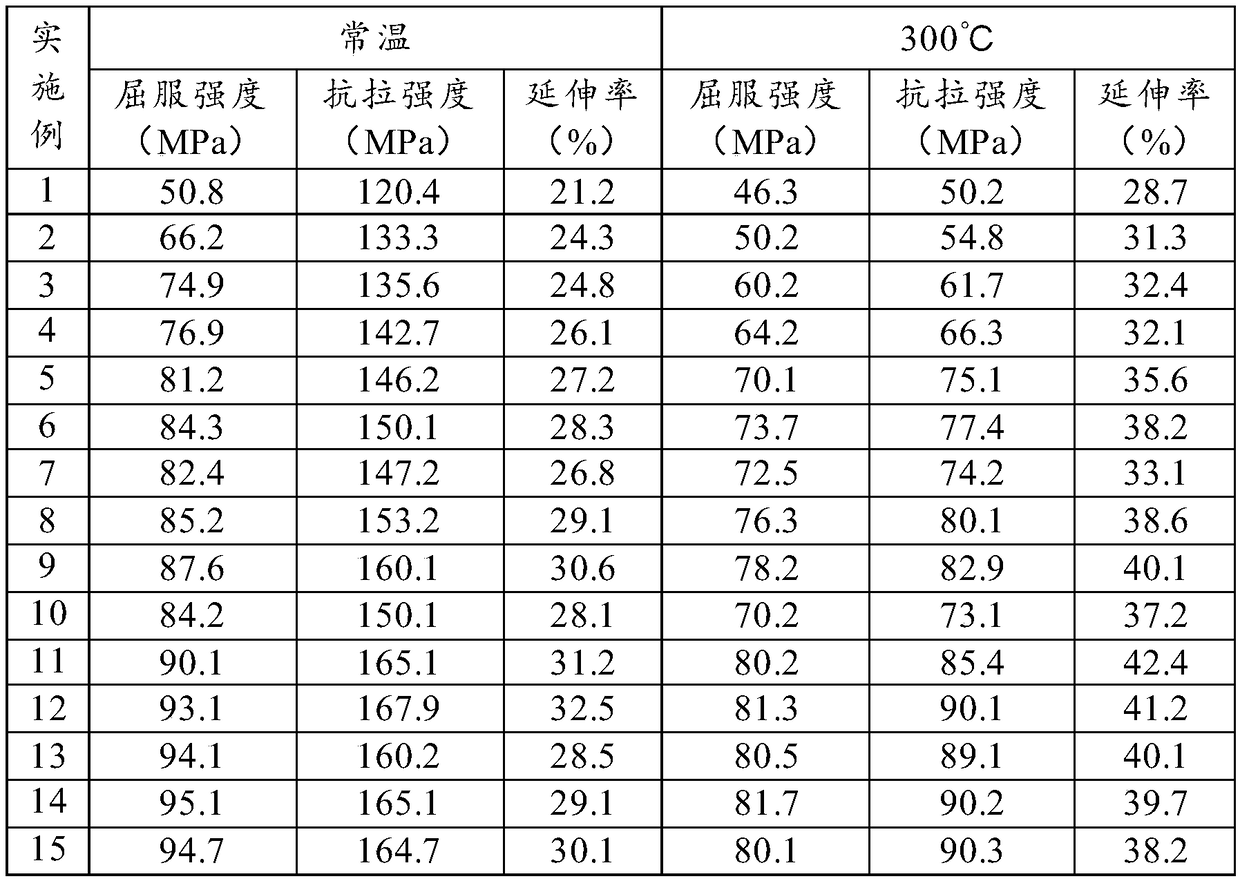

[0027] Table 1 shows the weight content of each element in the aluminum alloys of Examples 1-15

[0028] Example

Ce

B

Fe

Cu

Sc

1

0

0

0.6

0.2

0

2

0

0

1.50

0.15

0

3

0

0

2.61

0.25

0

4

1.04

0.03

1.72

0.31

0

5

1.22

0.01

1.73

0.34

0.15

6

1.65

0.04

1.77

0.43

0.21

7

1.18

0.02

1.69

0.43

0.23

8

2.28

0.03

2.64

0.32

0.25

9

2.42

0.05

2.6

0.27

0.34

10

2.23

0.02

2.55

0.33

0.38

11

2.13

0.01

2.58

0.17

0.41

12

2.62

0.03

2.46

0.44

0.48

13

3.13

0.02

3.32

0.37

0.35

14

3.45

0.03

3.56

0.31

0.41

15

3.67

0.02

3.74

0.24

0.35

[0029] The preparation method of the aluminum alloy described in the above embodiments is:

[0030] 1) Calculate the quality of the required...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com