Positioning and rectification device for pile body reinforcing bar cage

A technology of correction device and steel cage, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of increasing the danger of workers, increasing the workload of workers, and increasing the sediment at the bottom of the pile, so as to reduce the construction risk and reduce the Worker workload and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

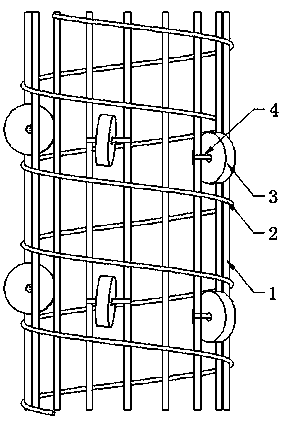

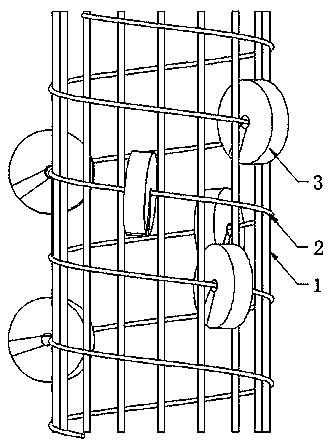

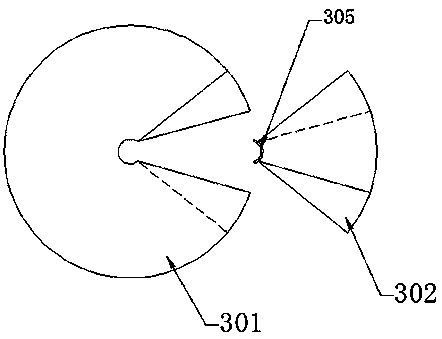

[0034] According to the engineering requirements, drill the pile holes, prefabricate the reinforcement cage, prefabricate the annular pad 3 according to the required thickness of the reinforced concrete protective layer, and then according to the depth of the pile hole, place stirrups of the same section every two meters along the length direction of the main reinforcement 1 2 is provided with a group of annular pads 3, the number of each group of annular pads 3 is greater than 3 and is evenly arranged on the stirrup 2 along the circumferential direction, generally each group uses 4 annular pads 3; open the small fan-shaped pads 302 Put the large sector pad 301 on the stirrup 2, and insert the small sector pad 302 according to the staggered meshing direction of the team until the limit rubber block 305 is reset to realize the positioning of the large sector pad 301 and the small sector pad 302 ;

[0035] When the reinforcement cage is hoisted by the hoist and ready to be lower...

Embodiment 2

[0037] The structure of the simple annular cushion block involved in the present invention, under the condition that other structures remain unchanged, can be that the stopper rubber block 305 realizing the radial limit function consists of two steps of the large sector-shaped cushion block 301 and the small sector-shaped cushion block 302 The positioning holes that cooperate with each other are set on the surface and the concave surface instead, and then the radial limit function is realized through bolt connection.

[0038] To sum up, through the improvement of the ring-shaped block of the existing steel cage structure, a pile body steel cage positioning and deviation correction device has the function of conveniently inserting the stirrup and rolling the steel cage down, thereby reducing the impact on the pile. Scratching of the hole wall reduces the cost, reduces the workload of workers and reduces the risk of construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com