Prefabricated steel-concrete hybrid frame structure and construction method based on composite beams

A frame structure and construction method technology, applied in the direction of building structure, construction, etc., can solve the problems of difficulty in ensuring the connectivity of concrete sections, complex connection node structures, and poor integrity of the frame system, so as to ensure safe and efficient construction and low construction difficulty , the effect of small on-site workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

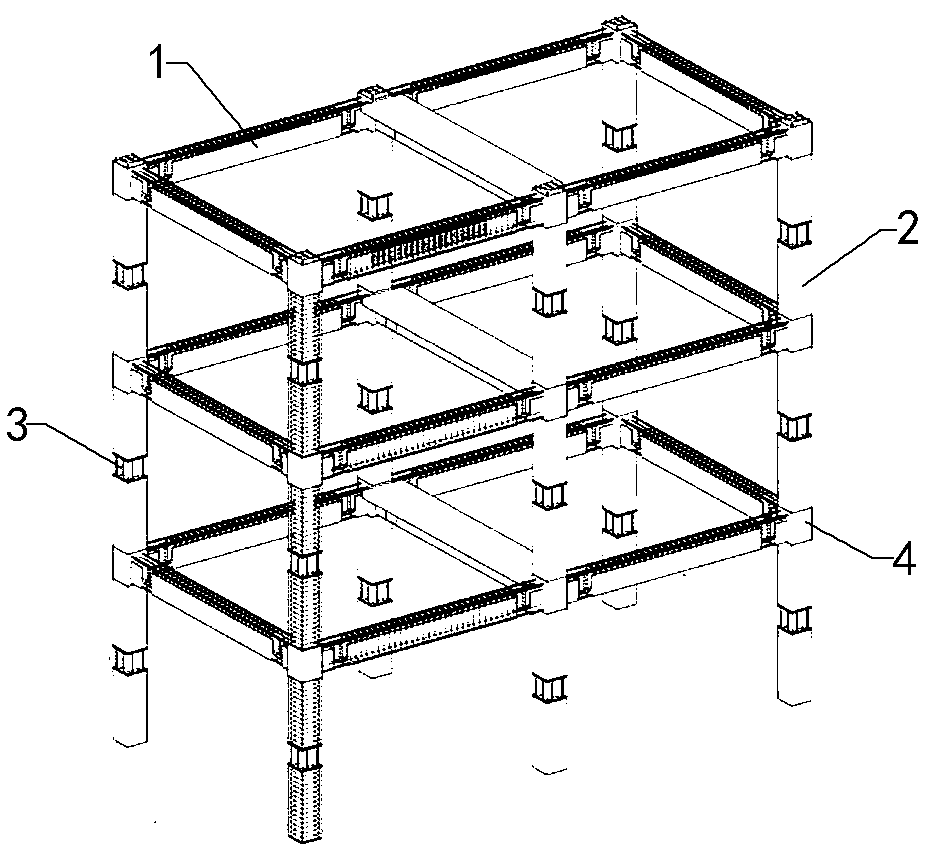

[0053] Such as Figure 1 to Figure 11 As shown, the assembled steel-concrete hybrid frame structure based on composite beams of the present invention includes a steel-concrete composite beam 1, a steel-concrete hollow column 2, and a core node connecting device connecting the steel-concrete composite beam 1 and the steel-concrete hollow column 2 4.

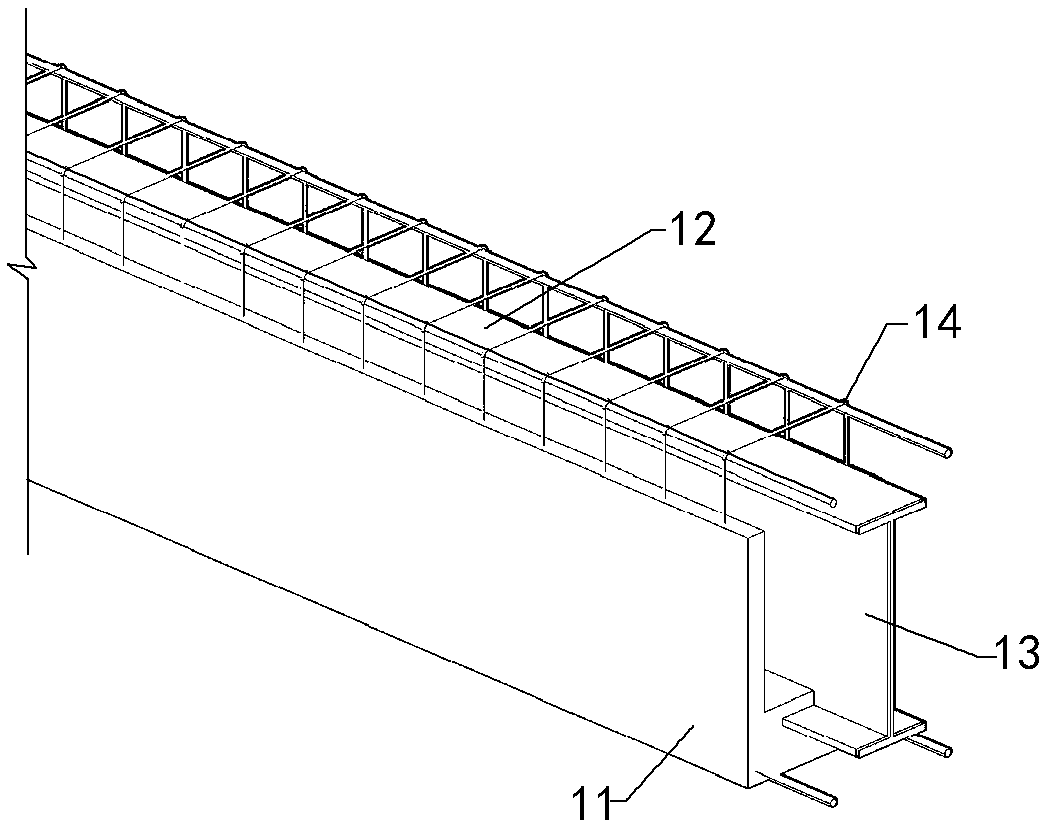

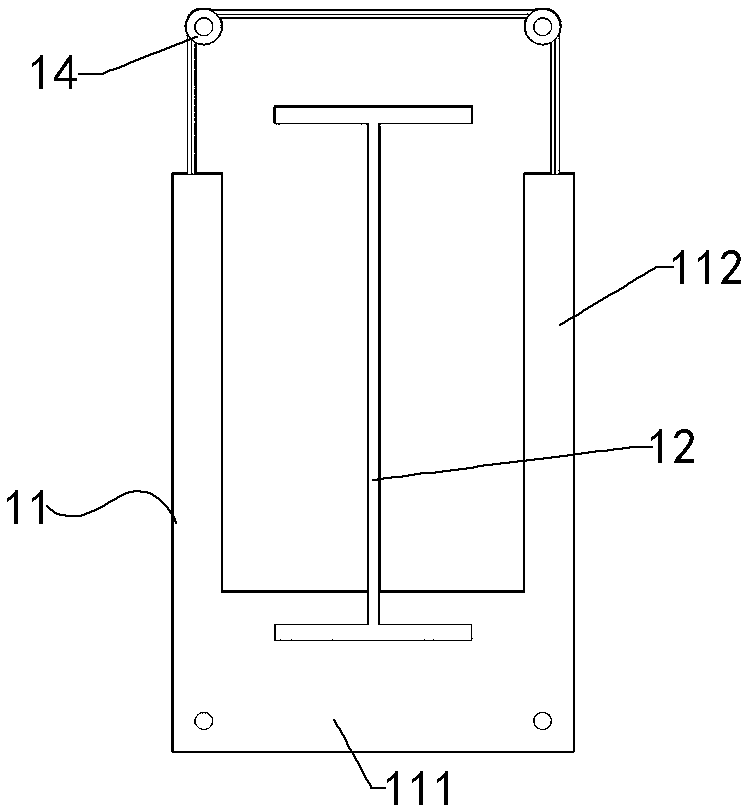

[0054] The steel-concrete composite beam 1 includes a prefabricated beam shell 11, beam core steel 12 and beam reinforcement skeleton 14 pre-embedded and fixed in the prefabricated beam shell 11, and a beam cast-in-place layer 15; the prefabricated beam shell 11 is prefabricated by high-strength concrete The U-shaped trough includes the beam bottom 111 of the steel-concrete composite beam 1 and the beam side walls 112 vertically arranged on both sides of the beam bottom 111, and the thickness of the beam bottom 111 is not less than 1 / 4 of the height of the steel-concrete composite beam 1; The beam core steel 12 is H-shaped steel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com