Large-diameter mud water shield tunneling machine transportation method for synchronous construction of high box culvert

A technology of simultaneous construction and transportation methods, applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as the inability to transport the excavation materials in time, the inability to maintain the close connection of the procedures, and the extension of the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The transportation method of the present invention is characterized in that the transportation system can realize continuous supply of materials required for excavation of the large-diameter slurry shield tunneling, and maintain the close connection of various processes.

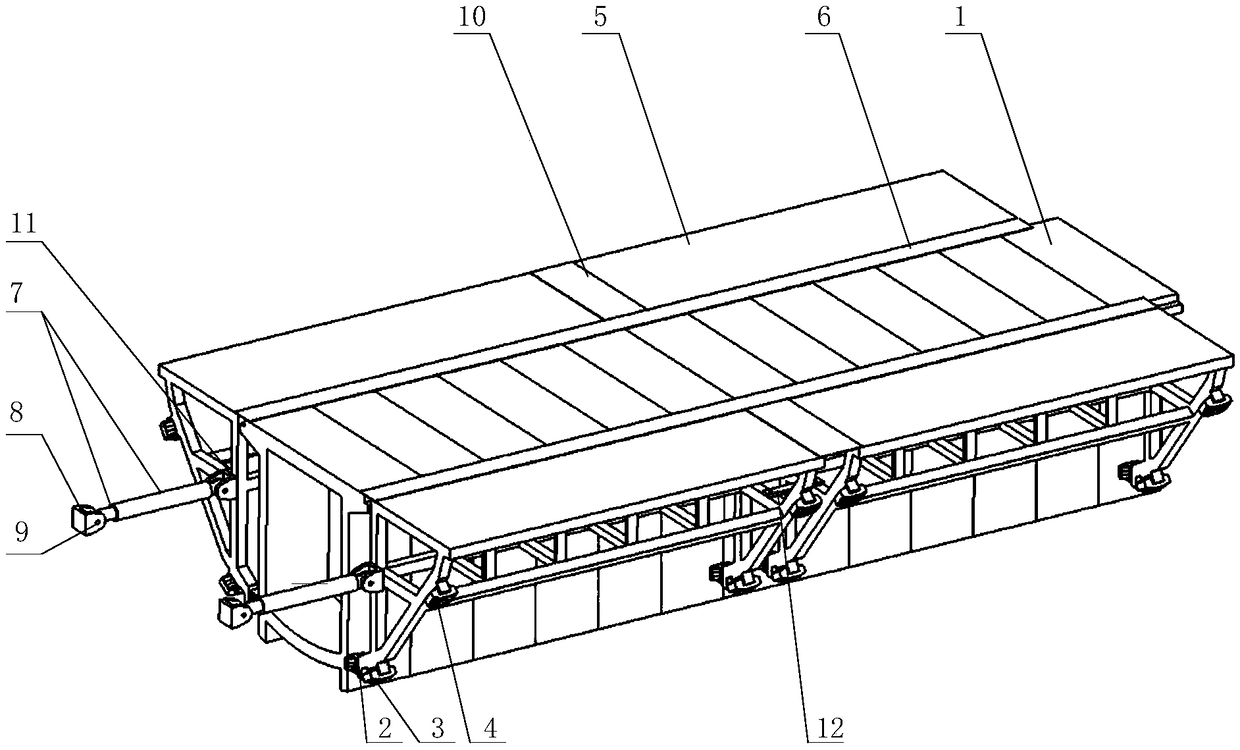

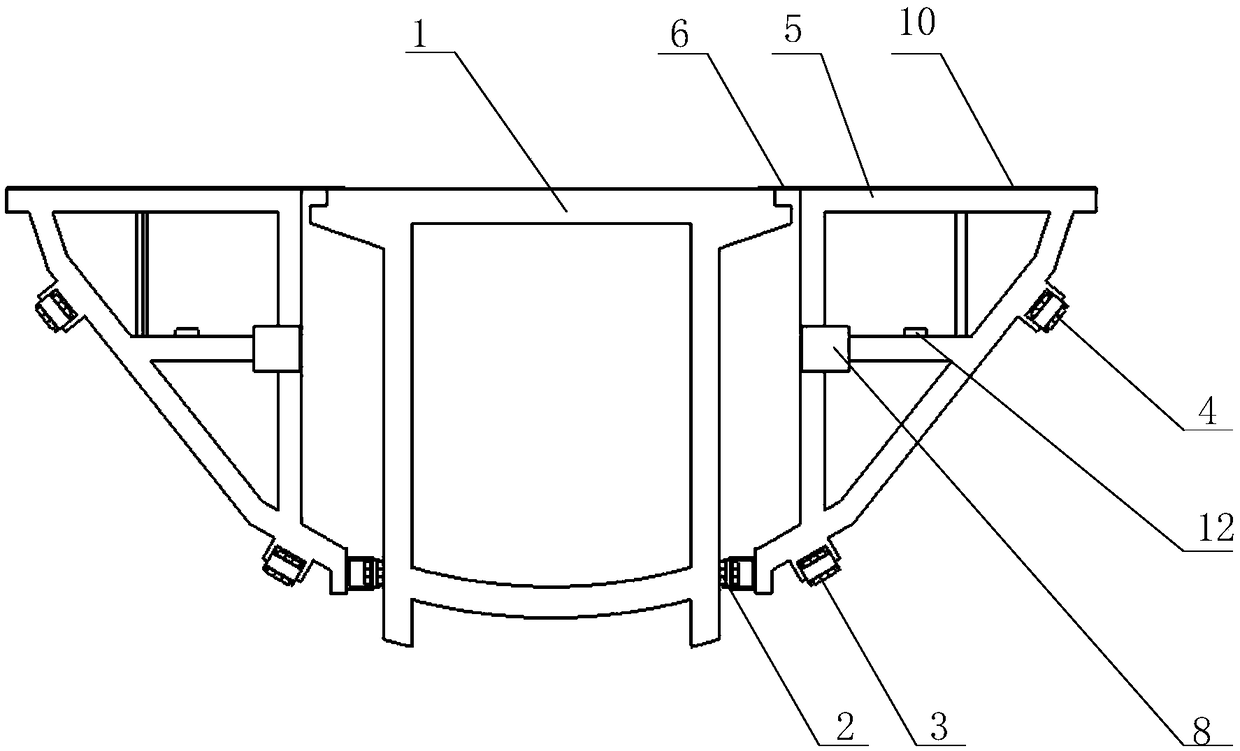

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

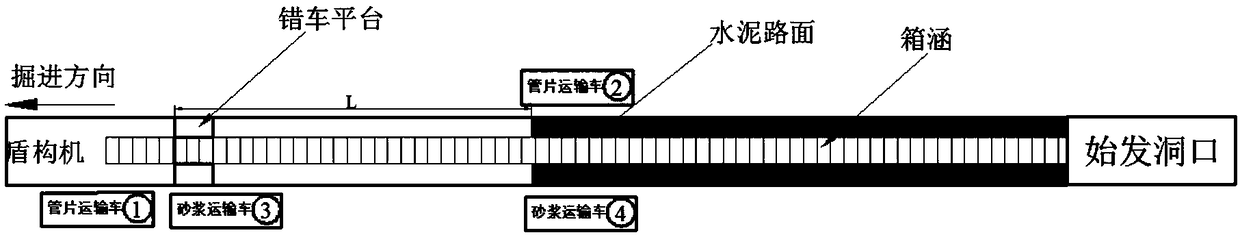

[0026] See figure 1 , the parking schematic diagram of the transport vehicle during one-time transportation of the present invention, the specific parking method is as follows:

[0027] Arrange two segment transport vehicles ①② and two mortar transport vehicles ③④ to enter the hole at the same time.

[0028] Segment transport vehicle ① and mortar transport vehicle ③ transport the segment and mortar to the end of the shield machine, mortar transport vehicle ③ puts mortar on the staggered platform, and segment transport vehicle ① unloads the segment.

[0029] Segment transport vehicle ② and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com