Winding follow-up pinch roller device for thin-film capacitor winding machine

A technology for film capacitors and winding machines, which is used in winding capacitor machines and other directions to achieve the effects of reducing friction, improving quality stability, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

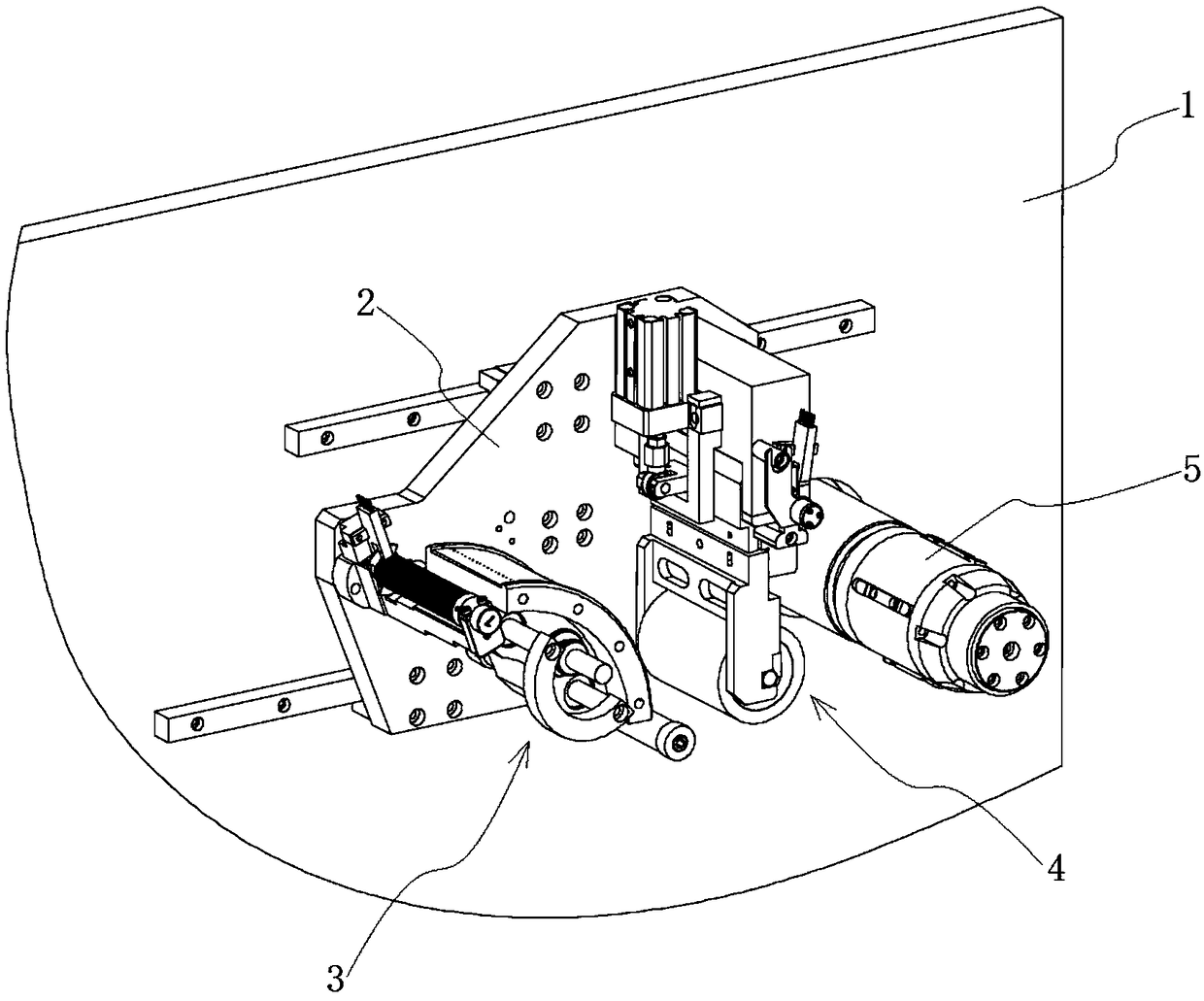

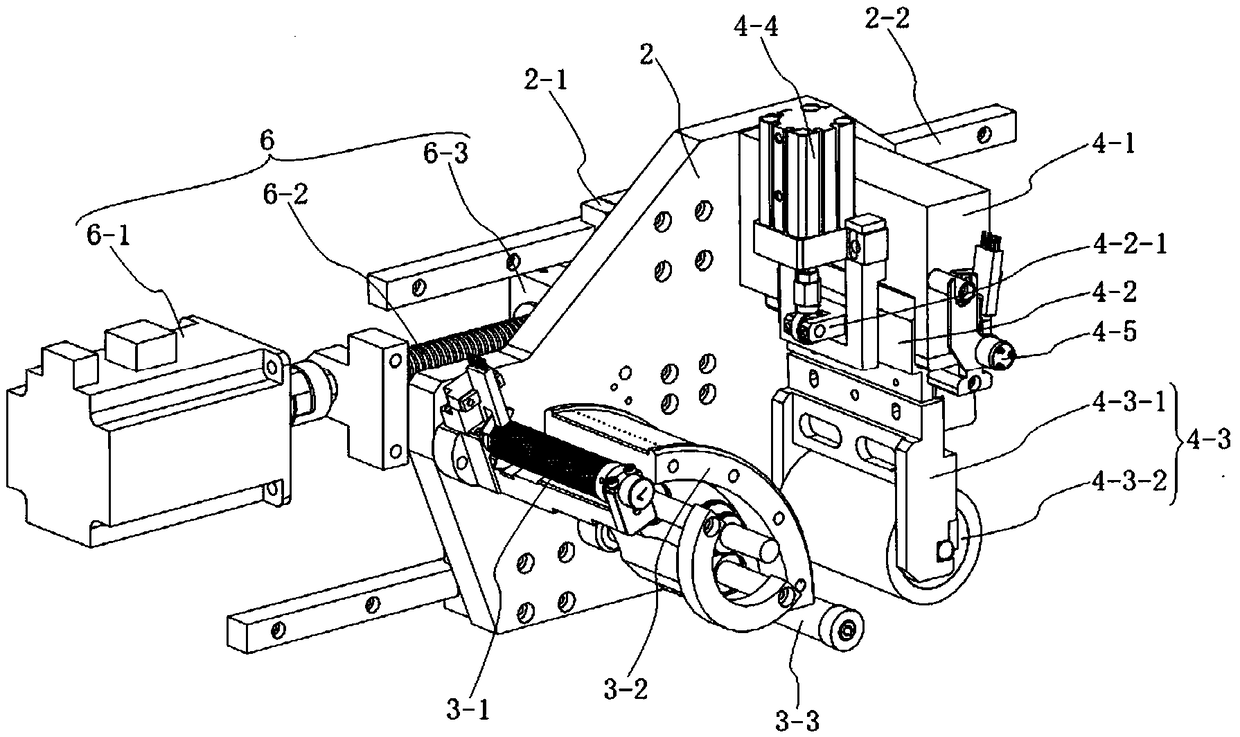

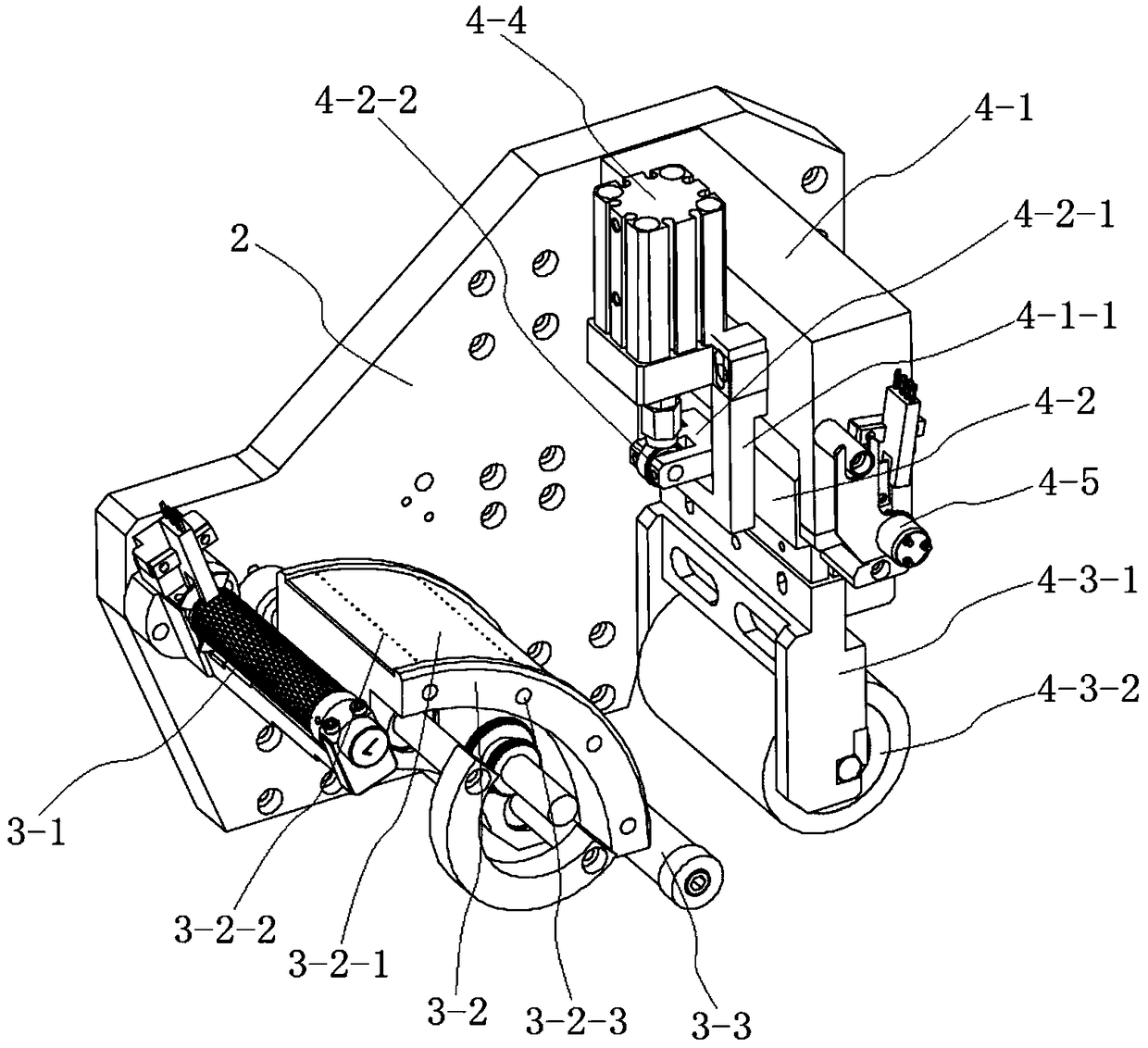

[0037] combine Figure 1 to Figure 5 As shown, a film capacitor winding machine of this embodiment is rewinding and following the pressure wheel device, which is installed on the substrate 1 and is located near the rewinding mechanism 5. The rewinding mechanism 5 in this embodiment can use existing materials The disk fixture is used to clamp the winding material disk on the fixture of the winding mechanism 5 and drive it to rotate to carry out the winding work of the metal film. The winding follower pressure wheel device includes a sliding bottom plate 2 slidably installed on the base plate 1, a following drive mechanism 6 for driving the sliding bottom plate 2 to move, and an air guide mechanism 3 and a pressure wheel mechanism 4 installed on the sliding bottom plate 2. Following the driving mechanism 6 drives the sliding bottom plate 2 to move and then drives the air conduction mechanism 3 and the pressing wheel mechanism 4 to move synchronously. see figure 2 , image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com