Mechanical arm hand-eye calibration method based on spatial distance and epipolar line constraint

A technology of spatial distance and hand-eye calibration, applied in the field of visual calibration, which can solve the problems of lack of constraint information, constraint information fusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with drawings and embodiments.

[0073] Embodiments of the present invention and its implementation process are as follows:

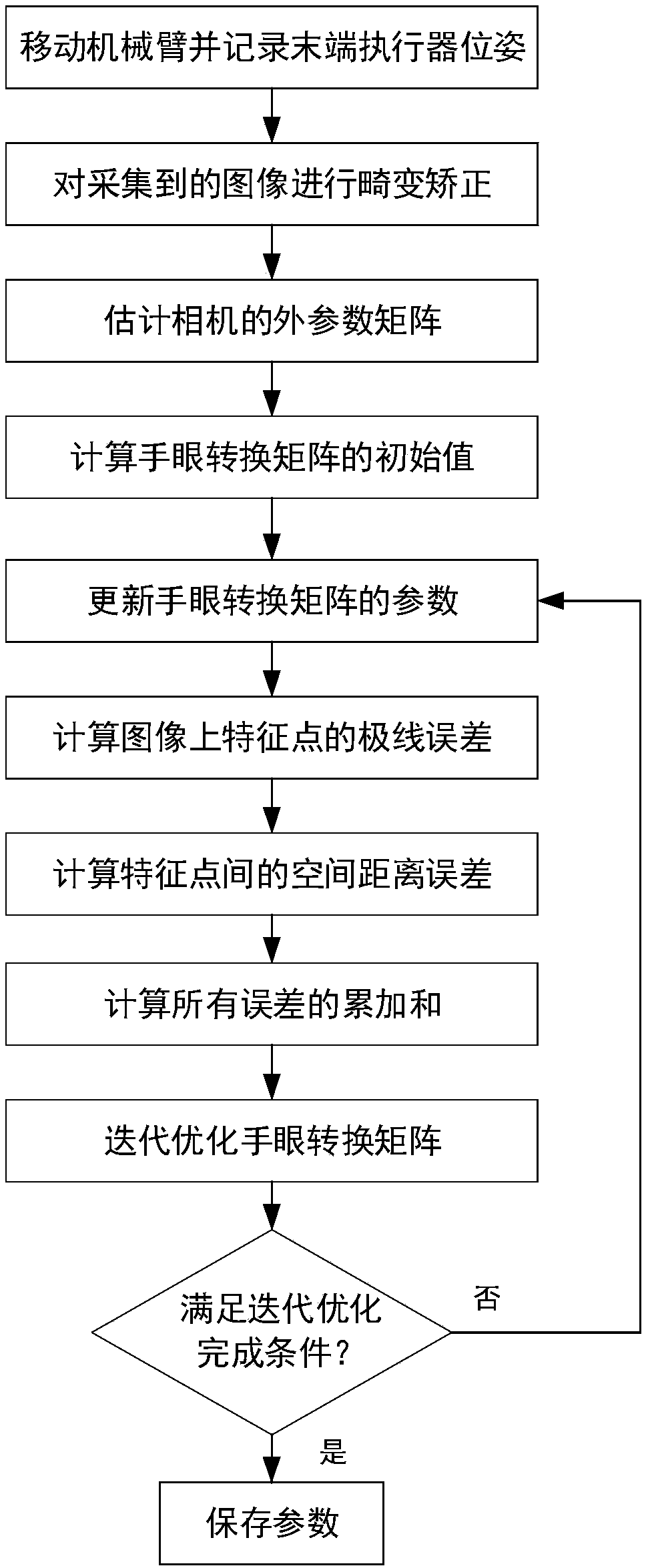

[0074] (1) figure 1 is a flow chart of the method of the present invention. The model of the robotic arm in this experiment is ABB-IRB-120, the model of the industrial camera is Basler-acA2440-20gm, and the model of the lens is Computar-M1224-MPW2.

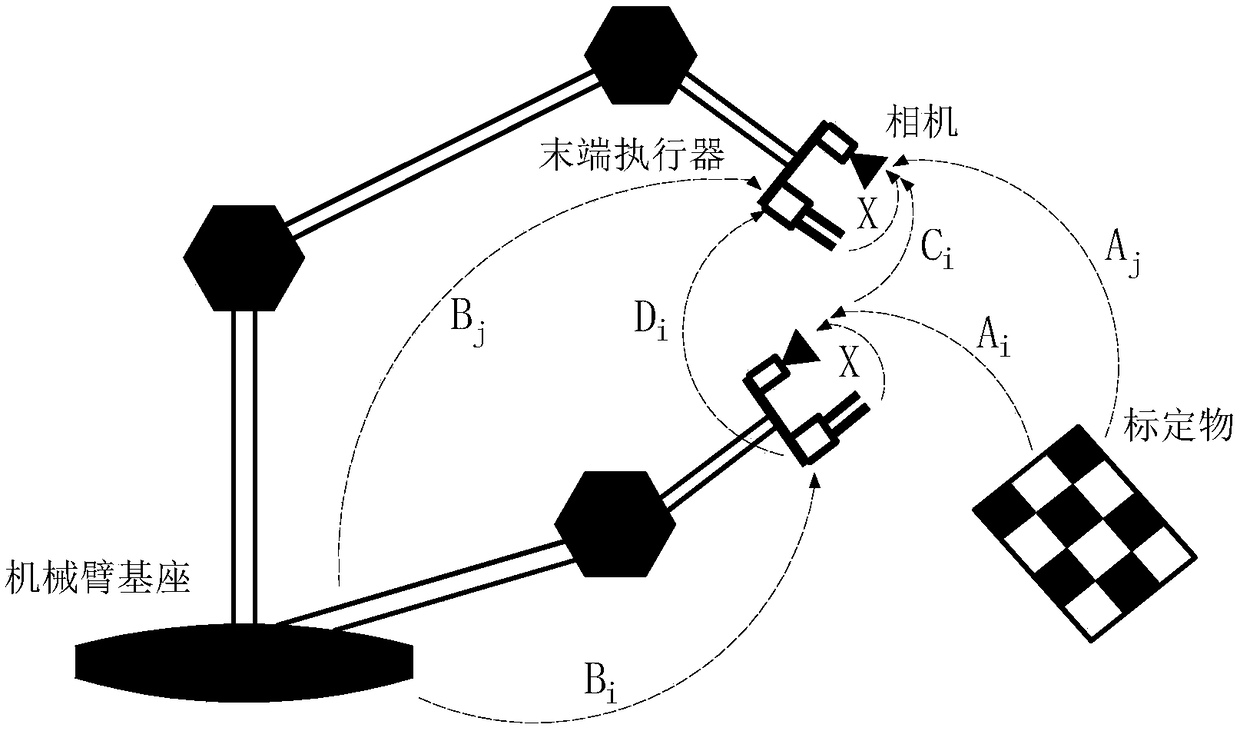

[0075] Such as figure 2 As shown, the manipulator includes the base of the manipulator and the end effector. The end effector is installed on the base of the manipulator. The end effector is equipped with a camera. The manipulator is located above the calibration plate. The surface of the calibration plate has a black and white chessboard pattern. The end effector moves the camera to take a complete image of the calibration plate;

[0076] The camera fixed on the end effector of the manipulator is calibrated using the Zhang Zhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com