Novel double-acting press machine

A press, a new type of technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of high manufacturing costs and complex structures, and achieve the effects of uniform division, simplified transmission structure, and large unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

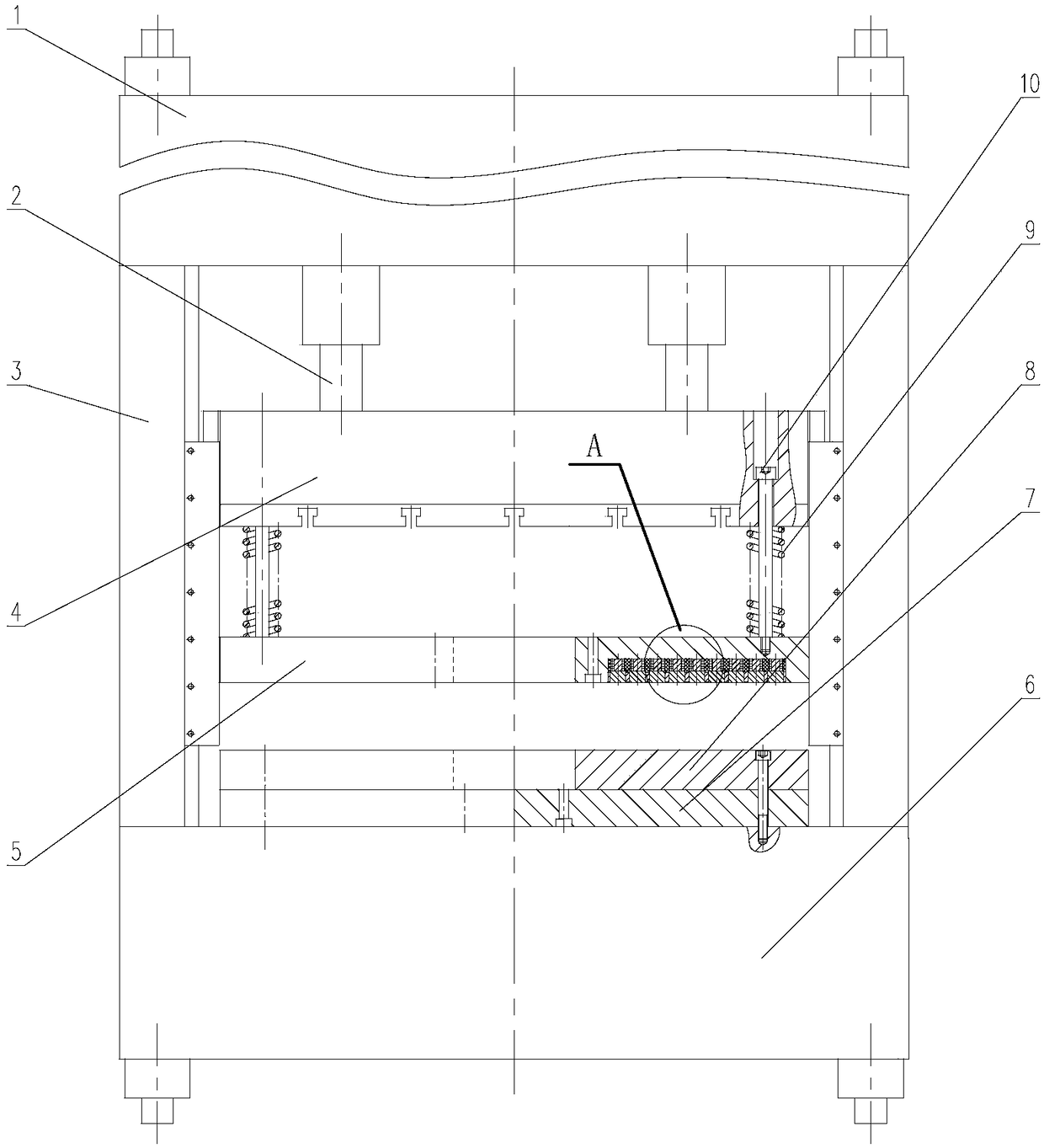

[0028] Such as figure 1 As shown, this embodiment includes: fuselage 3, upper beam 1, connecting rod 2, forming slider 4, clamping slider 5, spring 9, unloading screw 10, workbench 7, sucked plate 8, base 6 Wait. The fuselage 3 , the upper beam 1 and the base 6 are fixed together to form a frame, and the fuselage 3 is connected to the base 6 and the upper beam 1 . The driving system is fixed on the upper beam 1 and connected with the connecting rod 2, which can be a mechanical system or a hydraulic system or other power systems, such as hydraulic cylinders, hydraulic cylinders and the like. The connecting rod 2 drives the forming slider 4 to move along the guide rail. The mold clamping slider 5 is hoisted on the guide rail below the forming slider 4 by the unloading screw 10. There is a circular through hole in the middle of the mold clamping slider 5, and the circular through hole It is stepped. The magnetism changing device is arranged inside the clamping slider 5, which ...

Embodiment 2

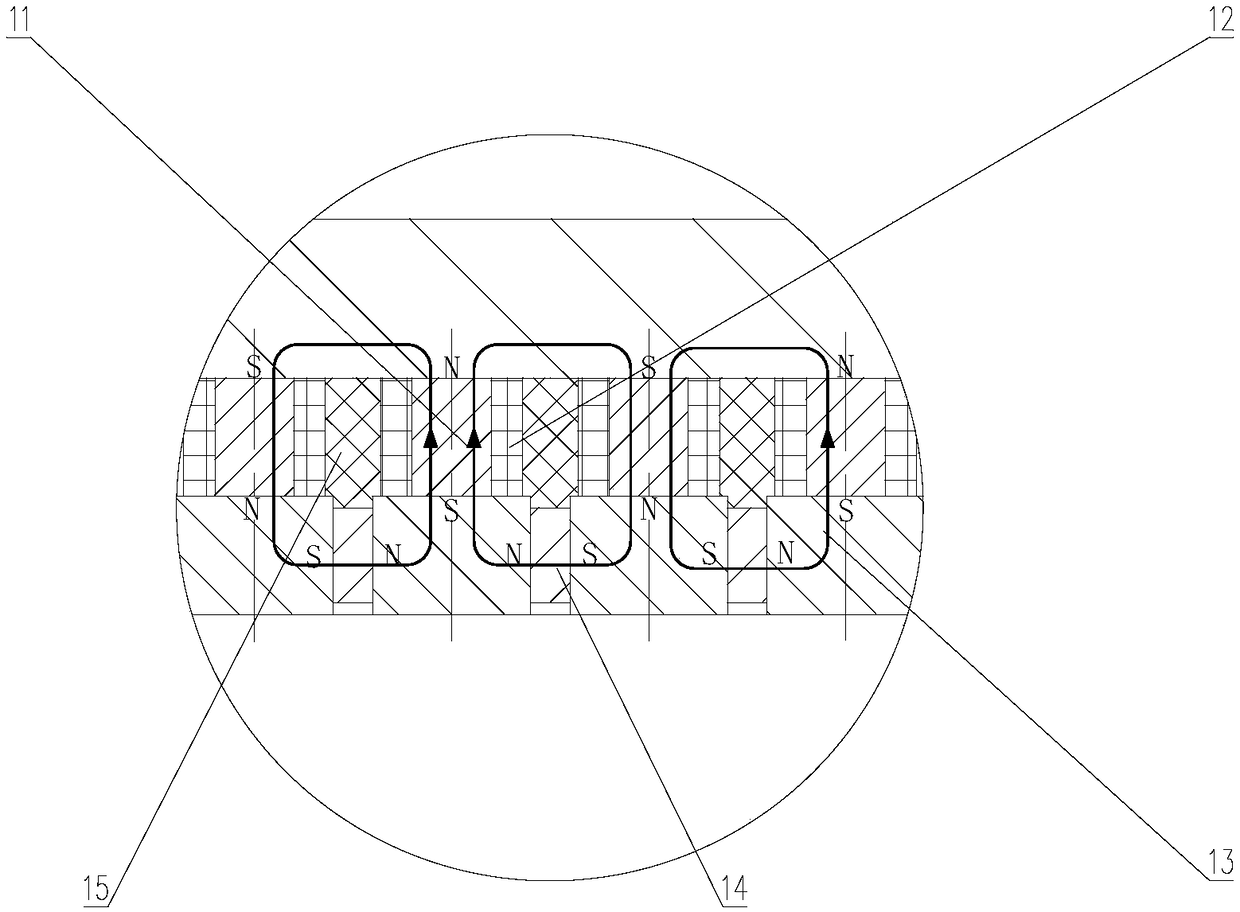

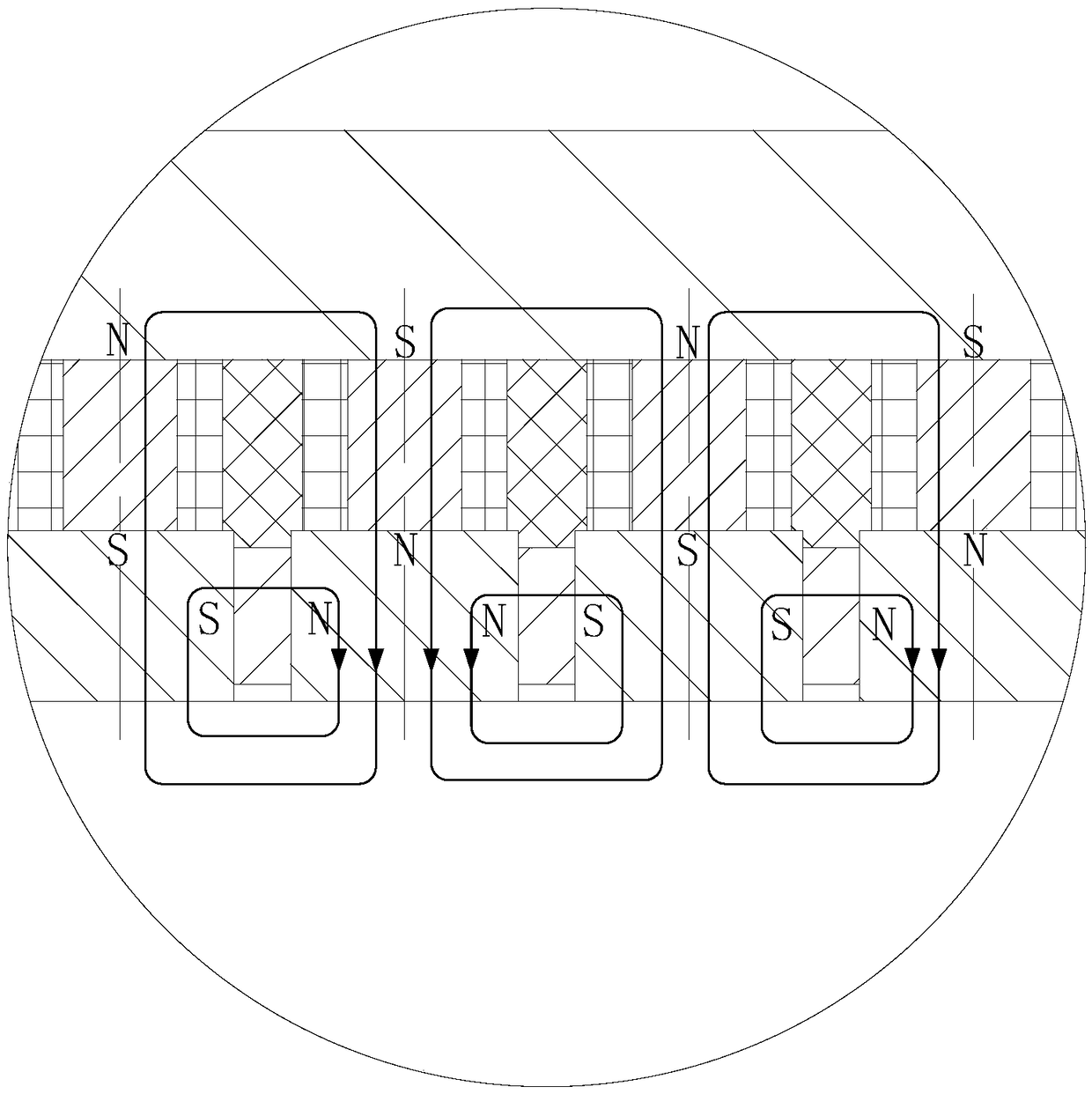

[0031] Such as Figure 3-4 As shown, the magnetic changing device inside the mold clamping slider described in this embodiment is a stacked electromagnetic pole unit layer and a magnetic conduction layer; the electromagnetic pole unit layer is formed by a plurality of electromagnetic pole units arranged side by side at equal intervals horizontally ; The electromagnetic pole unit includes an iron core 16, and a coil 17 wound on the iron core 16; the magnetic permeable layer is a plurality of magnetic permeable plates 18 that are respectively sealed to each electromagnetic pole unit, and around each permeable plate Inlaid very thin magnetic spacer block 19.

[0032] Such as Figure 4 As shown, the magnetic isolation block 19 is embedded in the magnetic conductive plate; a closed loop is formed to generate magnetic attraction.

[0033] In actual use, the working mode of the press machine is similar to that of Embodiment 1, but the magnetization mode of the magnetic pole unit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com