Anti-counterfeiting packaging integrated preparation process

A technology for preparation process and anti-counterfeit packaging, applied in the direction of printing device, printing, printing post-processing, etc., can solve the problems of increasing the difficulty of counterfeiting and imitation, and achieve the effects of increasing the difficulty of counterfeiting and imitation, facilitating adhesion, and small chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

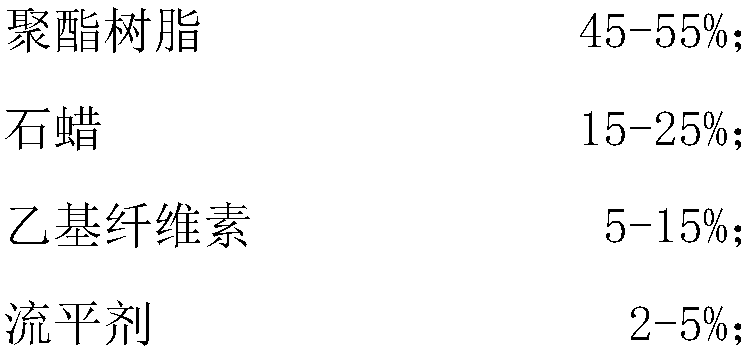

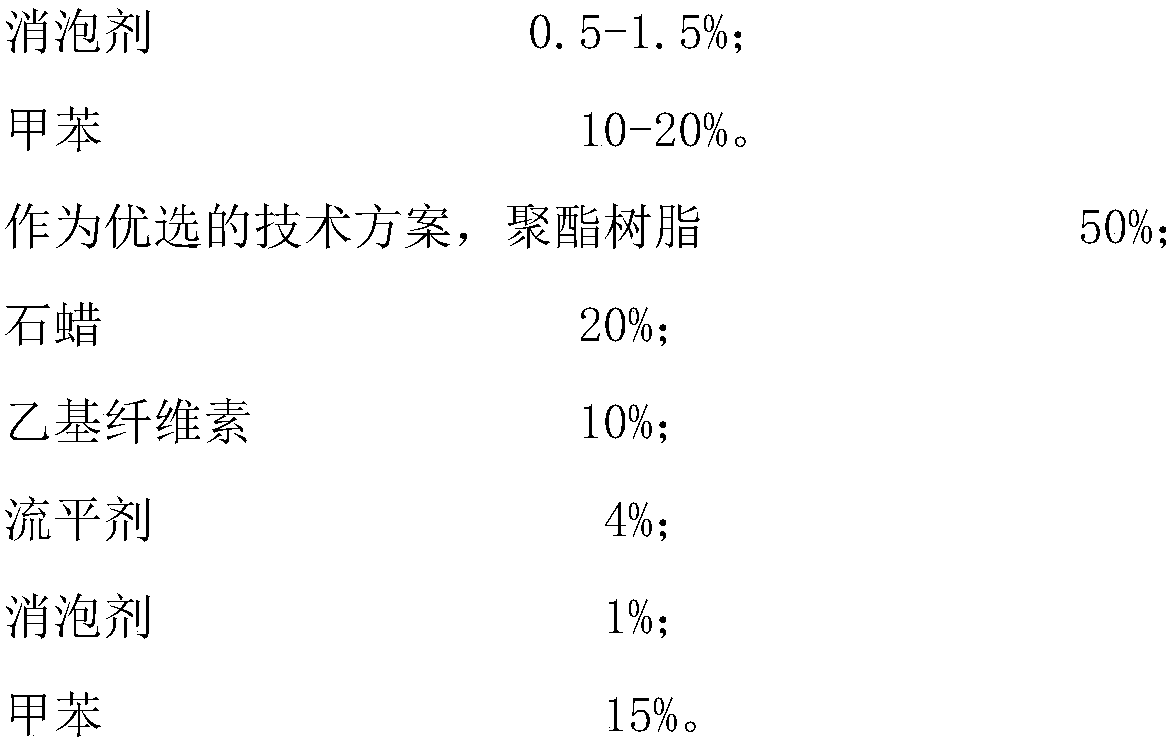

[0046] (1) Preparation of raw materials: Prepare raw materials including substrate film, VO solvent-based release agent, ink, and adhesive;

[0047] (2) Corona treatment: Corona treatment is carried out on the front and back of the substrate film, the corona value is 50 dynes, and the tension of the substrate film is guaranteed during corona treatment;

[0048] (3) Unwinding: Put the substrate film processed in step 1) in the center of the unwinding shaft of the gravure printing machine, pass between the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft. A DC pulsed ion bar is installed between the unwinding shaft and the embossing roller to synchronize with the operation of the gravure printing machine. The DC pulsed ion bar is located on the anti-counterfeiting required part of the substrate film. When the motor is turned on, the anti-counterfeiting required part of the substrate film conta...

Embodiment 2

[0058] (1) Preparation of raw materials: Prepare raw materials including substrate film, VO solvent-based release agent, ink, and adhesive;

[0059] (2) Corona treatment: Corona treatment is carried out on the front and back of the substrate film, the corona value is 65 dynes, and the tension of the substrate film is guaranteed during corona treatment;

[0060] (3) Unwinding: Put the substrate film processed in step 1) in the center of the unwinding shaft of the gravure printing machine, pass between the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft. A DC pulsed ion bar is installed between the unwinding shaft and the embossing roller to synchronize with the operation of the gravure printing machine. The DC pulsed ion bar is located on the anti-counterfeiting required part of the substrate film. When the motor is turned on, the anti-counterfeiting required part of the substrate film conta...

Embodiment 3

[0070] (1) Preparation of raw materials: Prepare raw materials including substrate film, VO solvent-based release agent, ink, and adhesive;

[0071] (2) Corona treatment: Corona treatment is carried out on the front and back of the substrate film, the corona value is 60 dynes, and the tension of the substrate film is guaranteed during corona treatment;

[0072] (3) Unwinding: Put the substrate film processed in step 1) in the center of the unwinding shaft of the gravure printing machine, pass between the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft. A DC pulsed ion bar is installed between the unwinding shaft and the embossing roller to synchronize with the operation of the gravure printing machine. The DC pulsed ion bar is located on the anti-counterfeiting required part of the substrate film. When the motor is turned on, the anti-counterfeiting required part of the substrate film conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corona value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com