Preparation method of activated carbon material based on tetrapanax papyriferus/juncus roemerianus interconnected porous structure

A porous structure and rush technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of limited carbon sources, complex processes, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

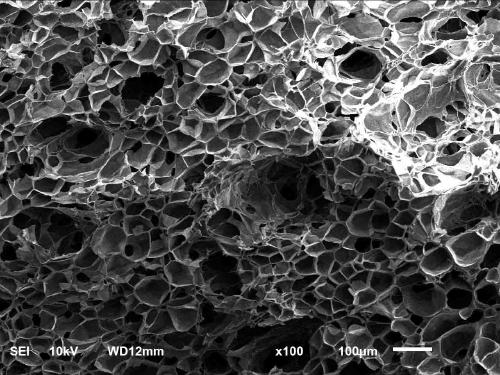

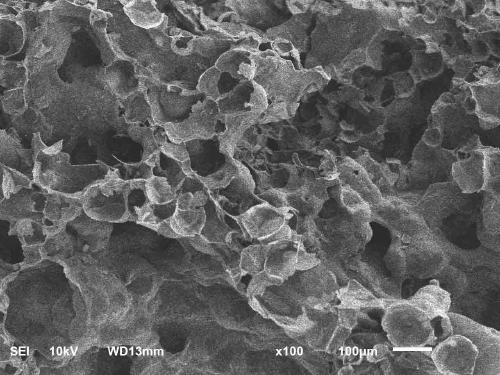

[0015] A preparation method based on the activated carbon material of Tongcao / Rush grass interconnected porous structure, comprising the following steps:

[0016] (1) Now pre-treat the grass or rushes by cleaning, segmenting, drying, etc., then put the grasses or rushes in a high-temperature furnace, pass inert gas, and heat them at 300-900°C (for example, 300°C, 600°C, 900°C, etc.) ℃) under carbonization for 0.5-8h (for example, 0.5h, 4h, 8h), to obtain the grass- or rush-based carbon materials;

[0017] (2) Proportion of the grass or rush grass-based carbon material and the activator: the mass of the grass or rush grass-based carbon material: activator = 1:0.5-8 (example 1:0.5, 1:4, 1:8) Mix and impregnate for 1-12h (example 1h, 6h, 12h), dry and grind at 50-120°C (example 50°C, 90°C, 120°C) to obtain the mixture;

[0018] (3) Treat the mixture at 300-900°C (example 300°C, 600°C, 900°C) for 0.5-8h (example 0.5h, 4h, 8h) under the protection of an inert gas, cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com