Line source device and OLED evaporation machine

A line source and evaporation technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of easy pollution and time-consuming opening of the cavity, so as to reduce the opening time, reduce pollution, reduce Effect of equipment feed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Please refer to the drawings in the accompanying drawings, wherein like reference numerals refer to like components. The following description is based on illustrated specific embodiments of the present application, which should not be construed as limiting other specific embodiments of the present application that are not described in detail here.

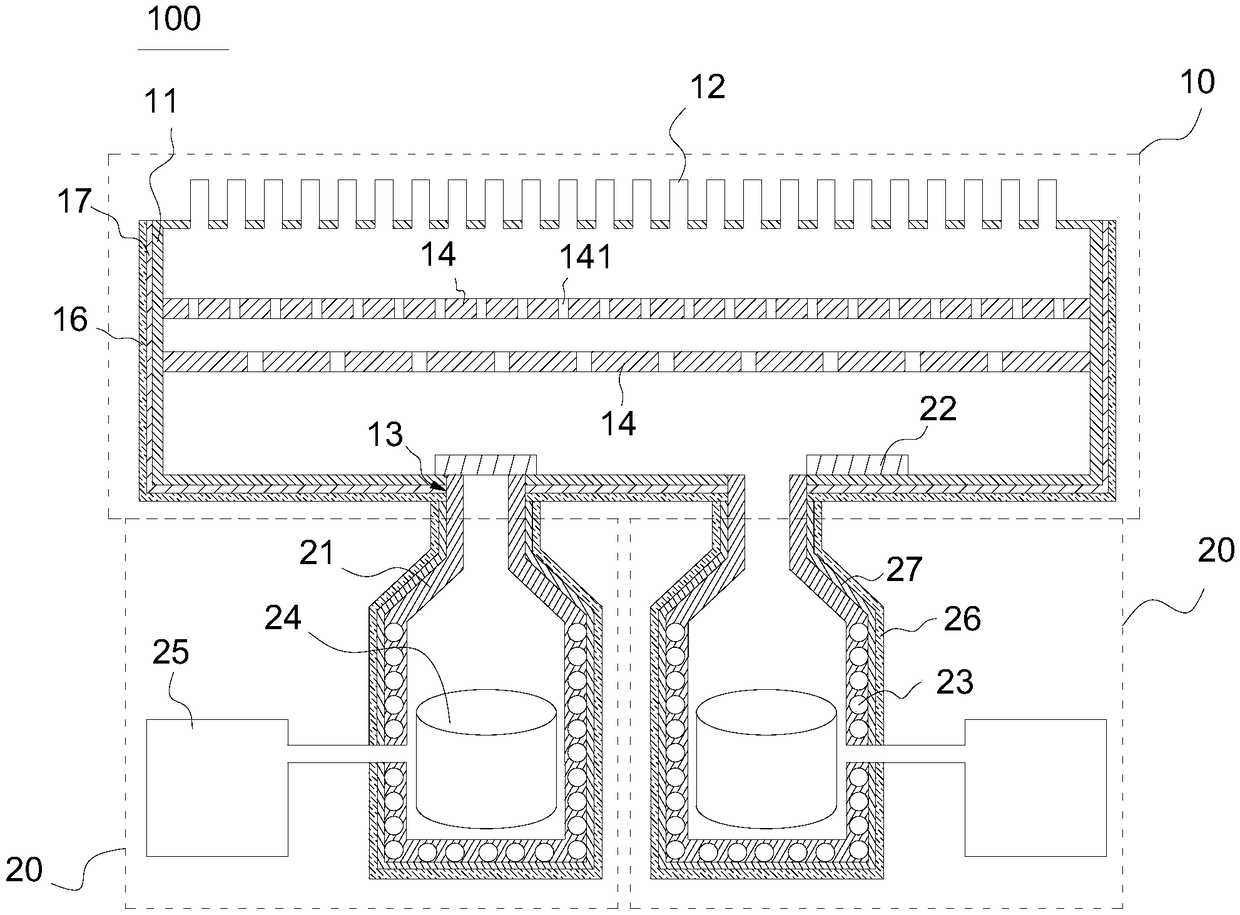

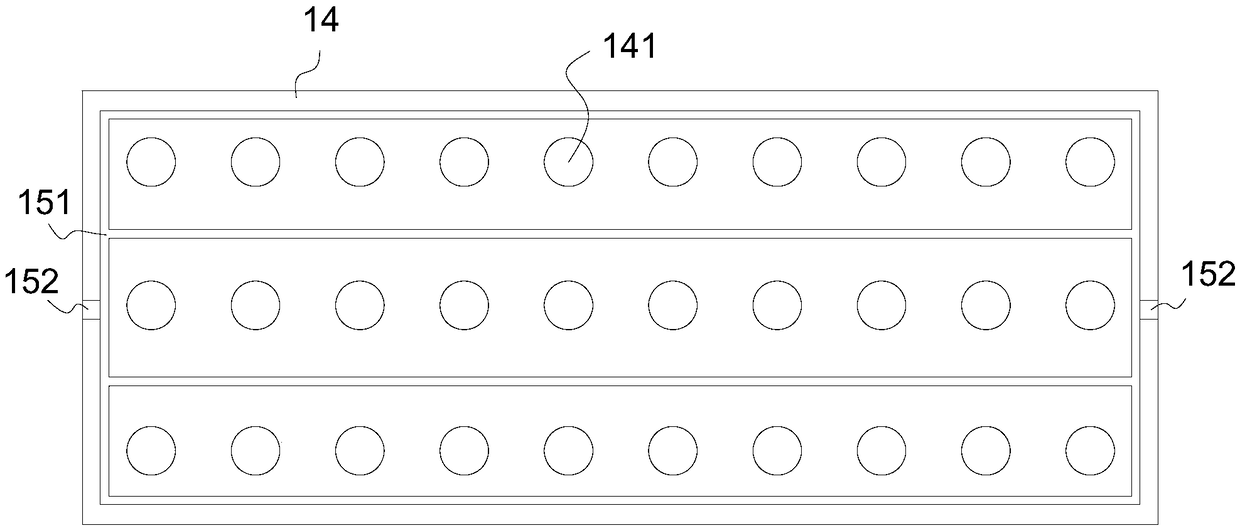

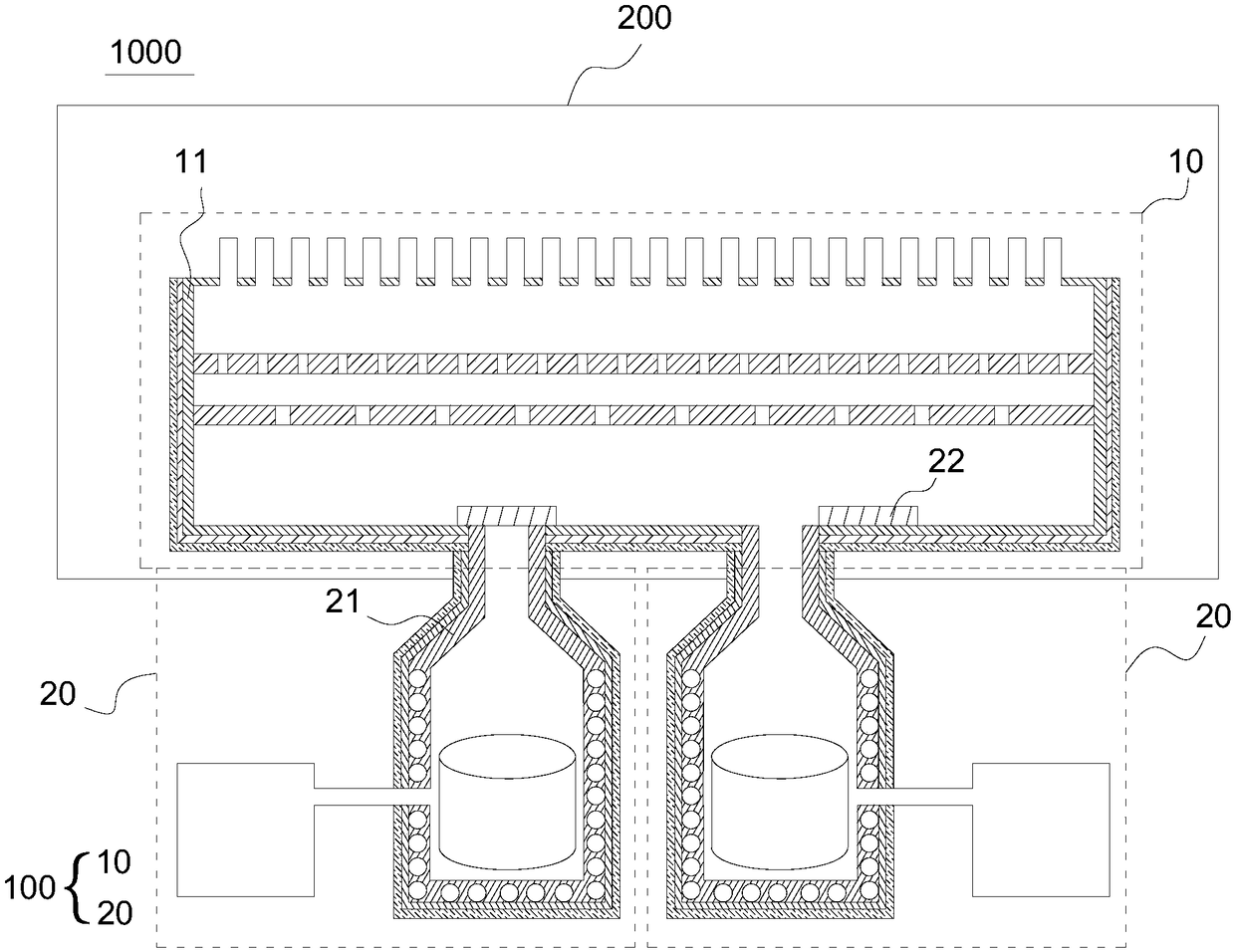

[0043] Please refer to figure 1 , figure 1 It is a schematic structural diagram of an embodiment of the line source device of the present application. The line source device 100 of the embodiment of the present application includes a line source mechanism 10 and at least two crucible mechanisms 20 .

[0044] The line source mechanism 10 is used for sputtering gaseous organic materials onto the external TFT substrate. The line source mechanism 10 includes a line source cavity 11 . The crucible mechanism 20 is used to provide gaseous organic material. Each crucible mechanism 20 is arranged outside the line source mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com