Gas inlet grid assembly and atomic layer deposition equipment

A technology for air intake grids and components, applied in coatings, gaseous chemical plating, metal material coating processes, etc., can solve problems such as abnormal discharge of power supply electrodes, abnormal film patterns, and abnormal patterns of films on the surface of wafers, so as to increase potential energy , Improve the stability and repeatability, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

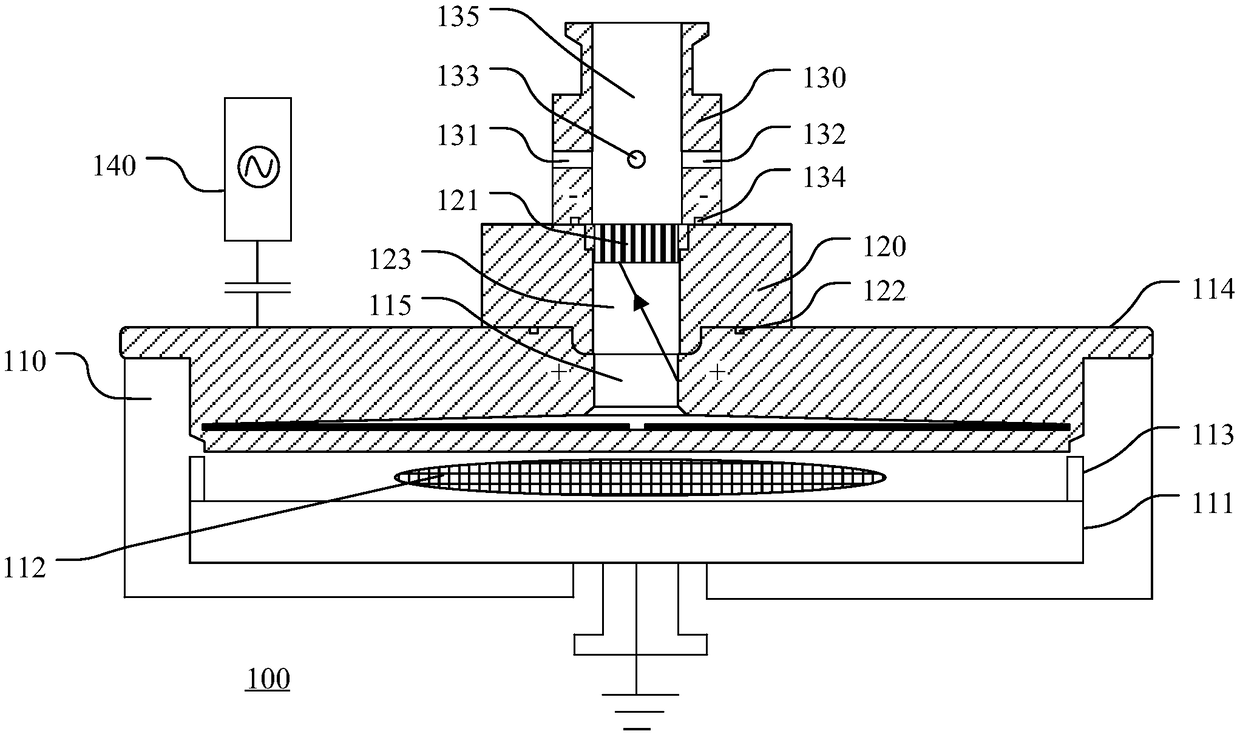

[0076] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0077] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

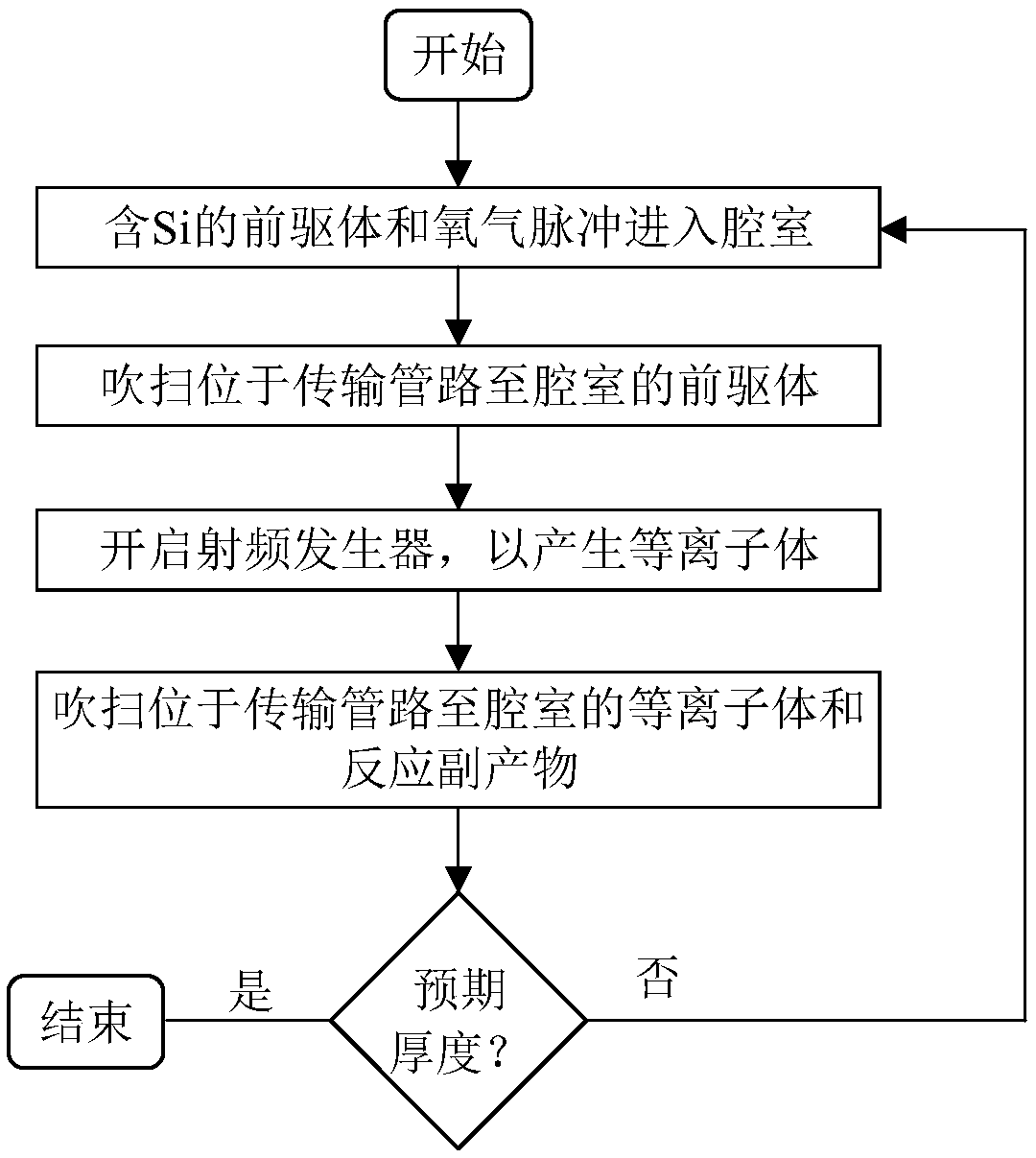

[0078] figure 1 A flow diagram of the plasma-enhanced atomic layer deposition technique is shown.

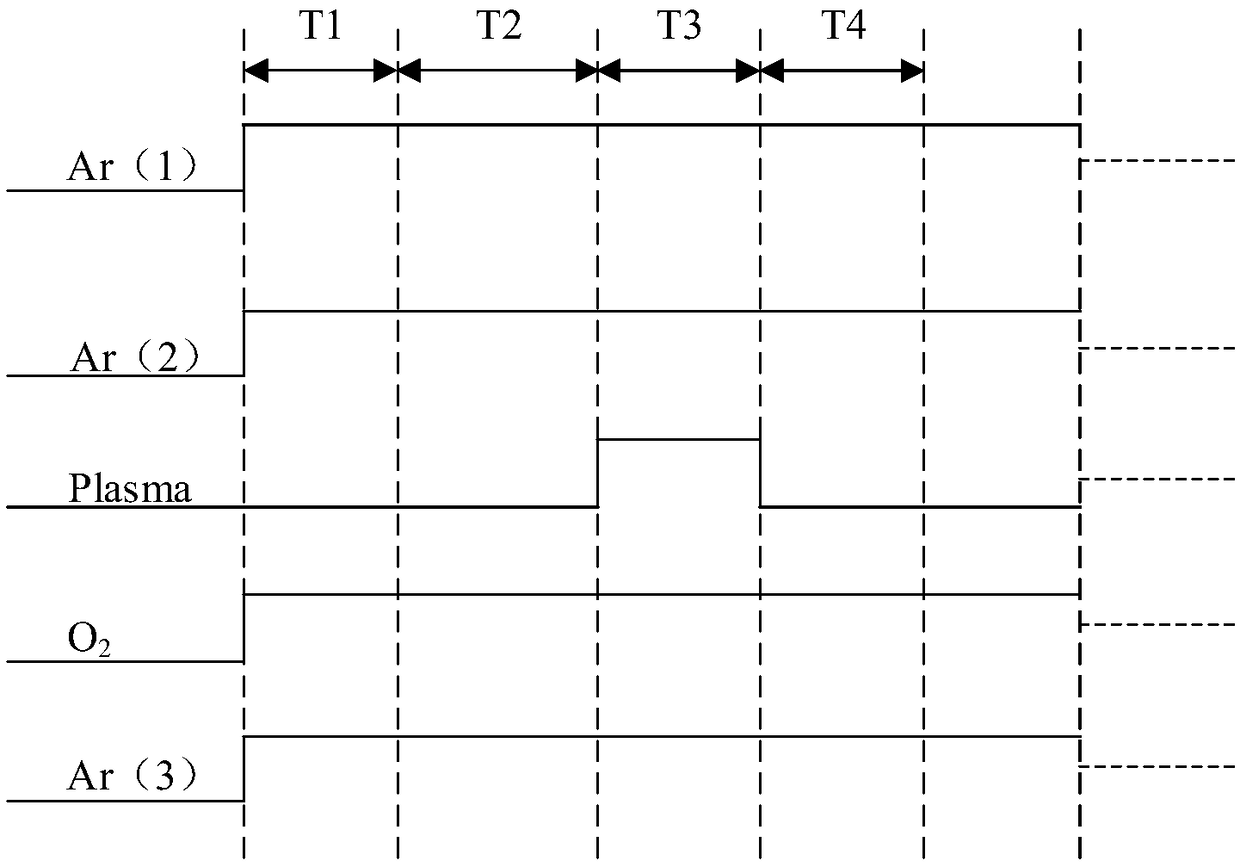

[0079] to deposit SiO 2 Thin film as an example, the existing PEALD deposited SiO 2 The deposition process of thin films generally uses Si-containing precursors and oxygen (O 2 ) scheme, the precursor (precursor) used is, for example, bis-diethylaminosilane (SAM24). Such as figure 1 As shown, in step S101, the Si-containing precursor and oxygen pulse enter the chamber until the substrate fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com