Graphene viscose/graphene modal interlaced yarn and its preparation method and fabric

A technology of ethene modal spun yarn and graphene, which is applied in the field of textile fabrics to achieve the effects of reducing yarn breakage, constant tension and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0038] Embodiment 1~7 a kind of graphene viscose glue / graphene modal cross and doubling yarn

[0039] raw material

[0040] Graphene dispersion, concentration 1.5mg / mL, purchased from Nanjing Xianfeng;

[0041] Viscose fiber was purchased from Tangshan Sanyou;

[0042] Modal fiber, purchased from Lenzing;

[0043] Process steps

[0044] a) preparation of graphene viscose composite fiber: mix graphene dispersion liquid and viscose according to formula quantity, spin to obtain graphene viscose composite filament;

[0045] b) Preparation of graphene modal composite fiber: mix graphene dispersion liquid and modal according to formula quantity, and spin to obtain graphene modal composite filament;

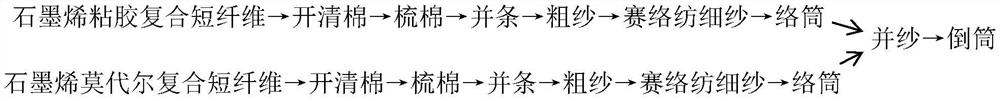

[0046] c) Yarn production: the graphene viscose composite filament and graphene modal composite filament prepared in steps a and b are cut into short fibers, and the graphene viscose spun yarn and graphene modal spun yarn are spun respectively by siro spinning technology, Then doub...

Embodiment 8~11

[0068] The interlaced yarns spun in Examples 1 to 4 were used to weave the mesh structure on a computerized flat knitting machine.

[0069] Technological process: doubling yarn → rewinding → knitting piece → sleeve → flat car → hand sewing → washing → drying → ironing → packaging

[0070] The process parameters are: horizontal density: 57.4 / 10cm; vertical density: 44.4 / 10cm; needle size: 12G; yarn: 50 S / 4 strands; Gram weight: 182 grams per square meter.

[0071] During the weaving process, factors such as different types of yarns, changes in the size of the bobbins, rapid rotation of the machine head, and temperature and humidity in the workshop will affect the tension of the yarns, which will lead to different yarn feeding volumes in each row, resulting in different coils in each row. Uniformity will eventually affect the deterioration of the apparent quality of the fabric. In order to improve this problem, the yarn guiding device and the yarn feeding device of the flat k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com