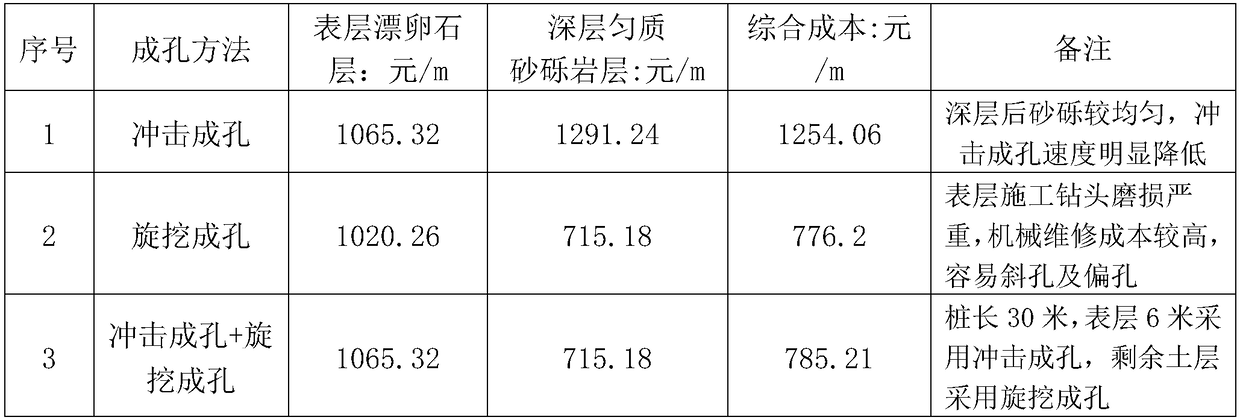

Construction method for pile foundation drilling of gravel stratum with floating pebble layer

A pebble layer and hole-forming technology, which is applied in infrastructure engineering, drilling equipment and methods, sheet pile walls, etc., can solve the problems of slow construction period and poor hole-forming quality, save economic costs and reduce pile foundation construction. The effect of cycle, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

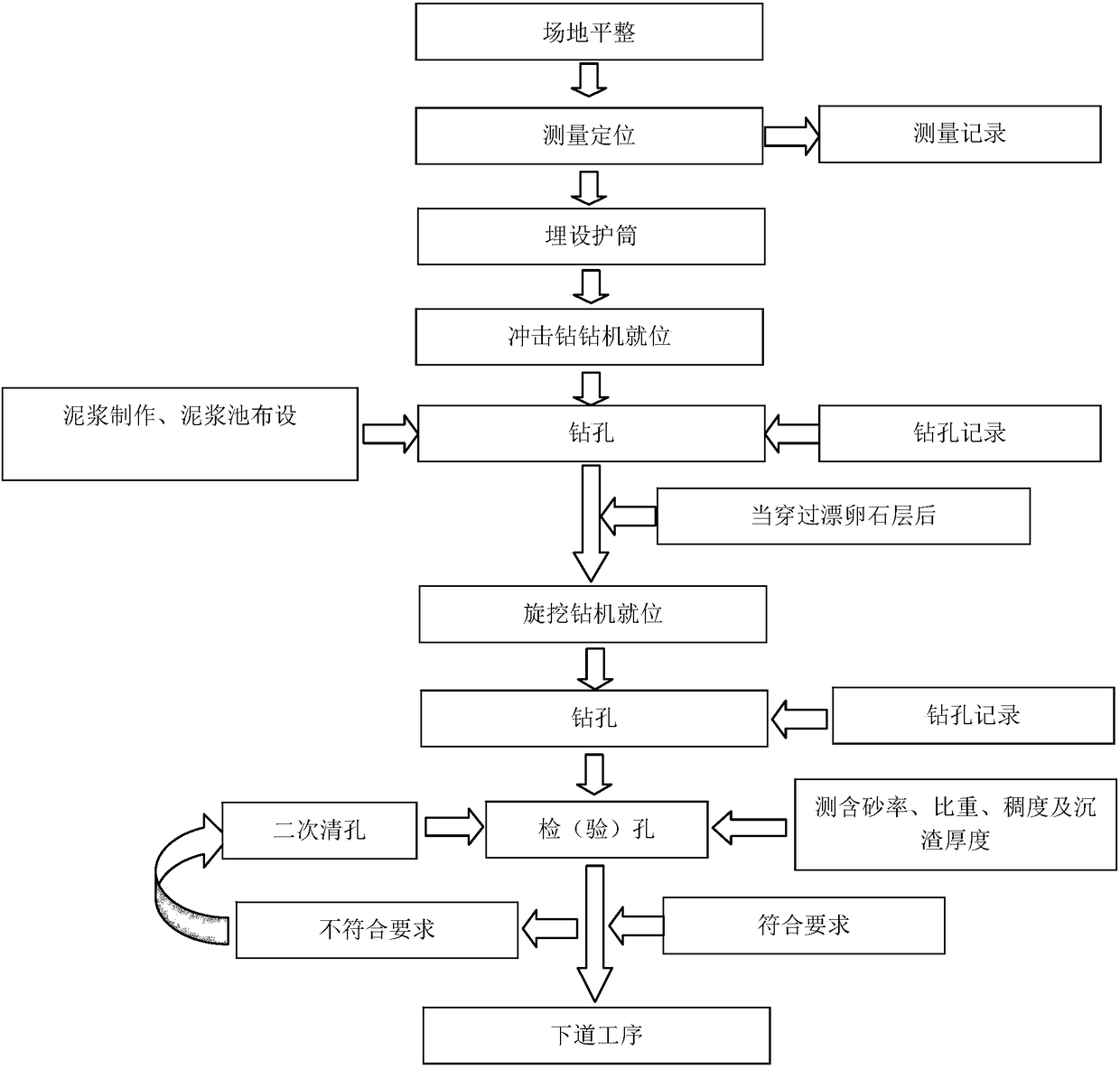

[0046] The specific implementation of the construction method of the present invention will be described in detail below with reference to the accompanying drawings.

[0047] The technical scheme of the present invention is specifically as follows:

[0048] 1. Buried protective tube, including:

[0049] 1) The protective tube is made of steel plate coil;

[0050] 2) Loft, dig pits, and put in steel protective tube according to the center of the pile position;

[0051] 3) Buried protection tube;

[0052] 2. Mud preparation, specifically including:

[0053] 1) Mud tanks are set up on site, including sedimentation tanks for slurry return and mud storage tanks;

[0054] 2) Wall protection mud regeneration treatment adopts gravity sedimentation and slag removal method, and the mud is transported to the mud storage tank after sedimentation and purification in the sedimentation tank for slurry return;

[0055] 3. The percussion drill drills into the hole, specifically including:

[0056] 1) Inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com