Ground source heat pump buried pipe construction method based on soil and rock alternate occurrence stratums

A technology of ground source heat pump and construction method, which is applied in the directions of heat pump, geothermal energy, earthwork drilling, etc., can solve problems such as inconvenient drilling operation, and achieve the effects of low hole forming cost, accelerated construction progress and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

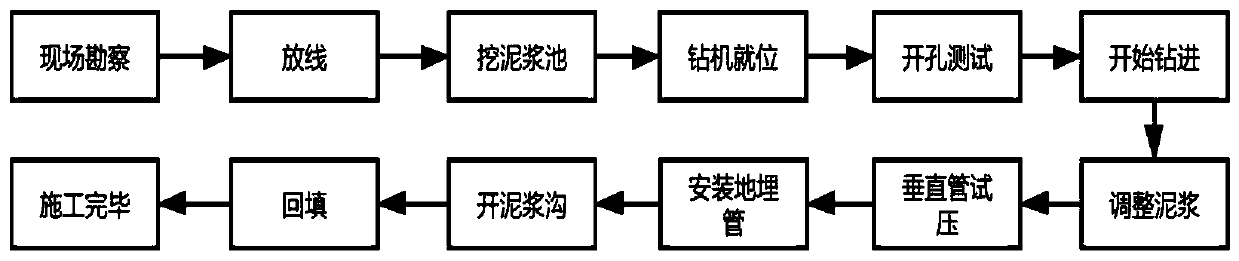

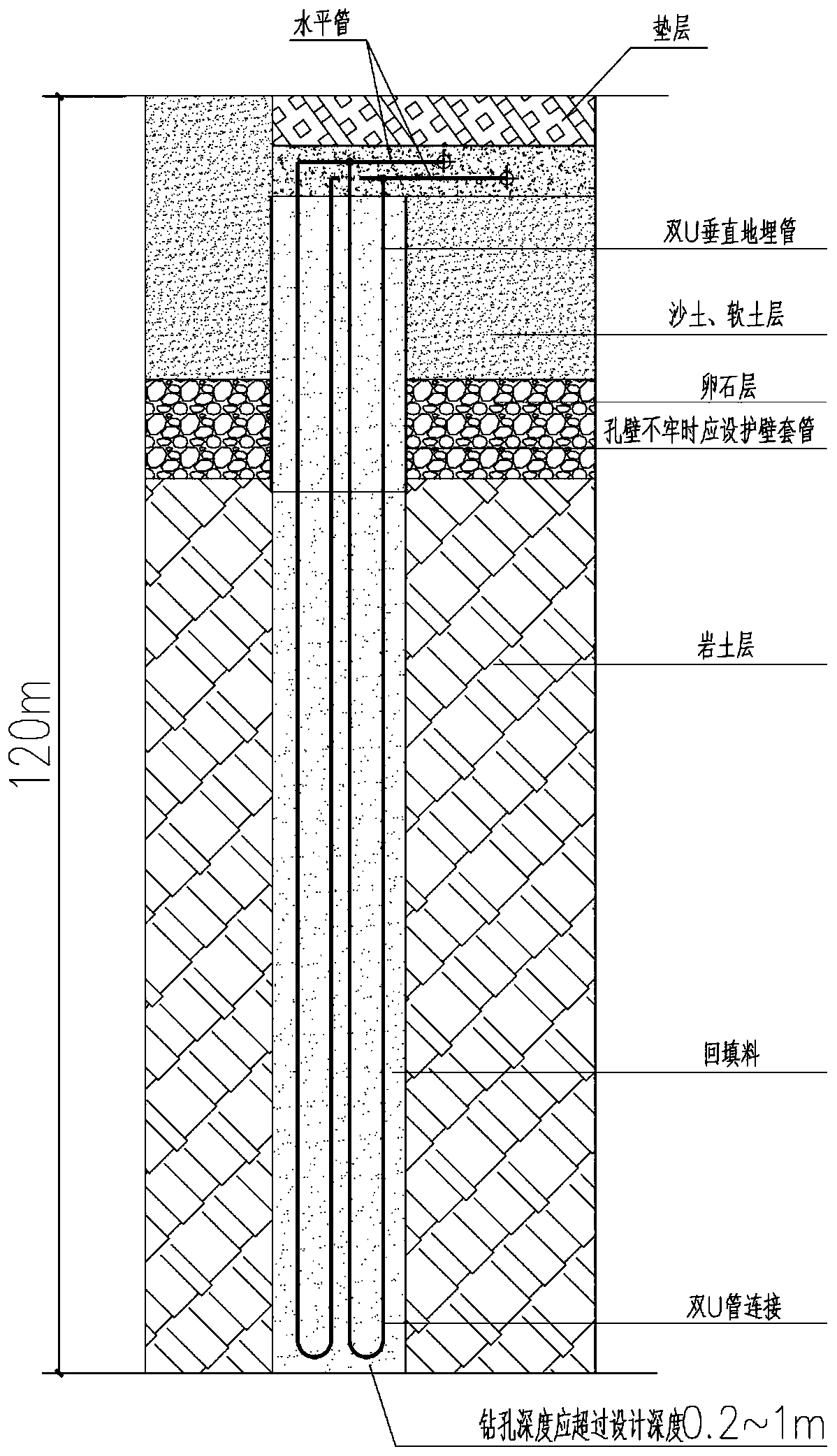

[0037] The ground-source heat pump buried pipe construction method based on the alternate formation of soil and rock of the present invention includes:

[0038] S1. Site measurement, setting out, positioning and circulation system adjustment; according to the site conditions, determine the orientation and spacing according to the X and Y axes of the general design drawing, and position on site in the form of wedged wooden piles. The vertical hole spacing for positioning should generally be between 4 and 6 meters, or determined according to the calculation of the soil heat balance value. If you encounter immovable obstacles such as municipal facilities, the well position should be adjusted appropriately; the drilling location should be far away from water wells and outdoors. drainage facilities.

[0039] S2. The drilling rig is in place. After the drilling rig is in place, the verticality between the drilling rig and the drill bit should be kept within a certain range, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com