A rod-taking mechanism for a core sampling drilling rig

A core sampling and rod mechanism technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problem of inability to realize alternate automatic grabbing of drill pipe or casing, not in line with efficient and sustainable economic development mode, large Human labor and labor costs, etc., to achieve the effect of improving and decreasing, improving construction efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

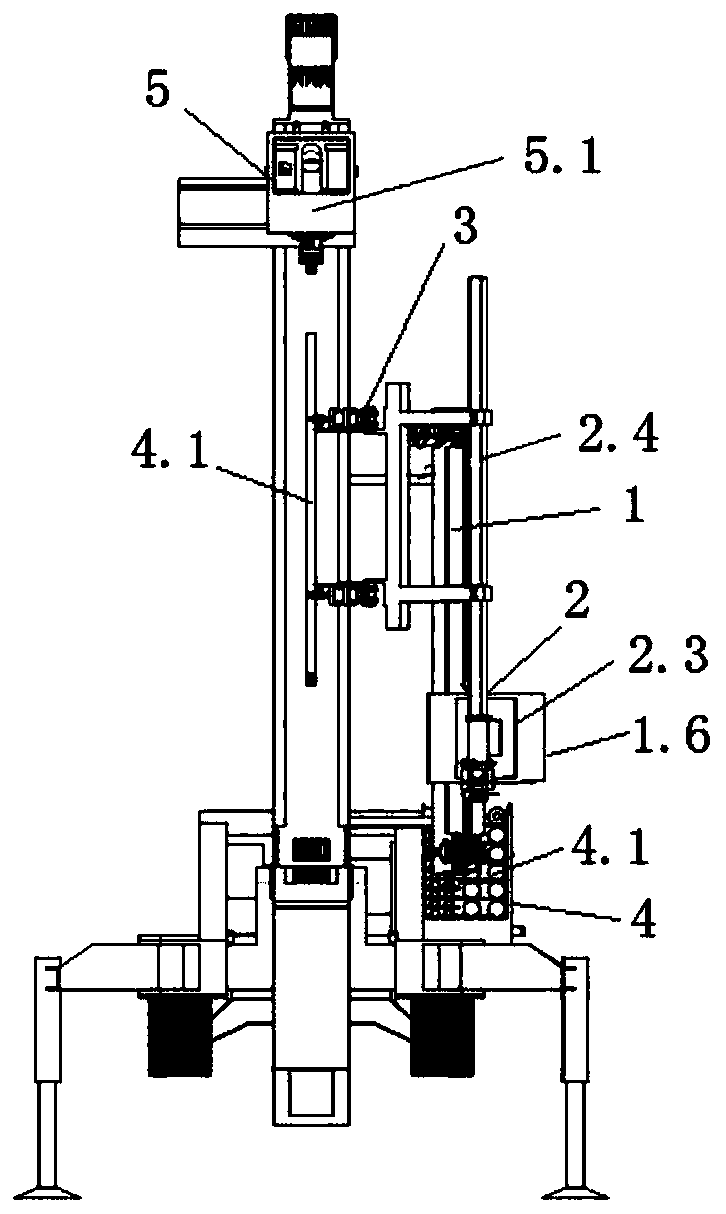

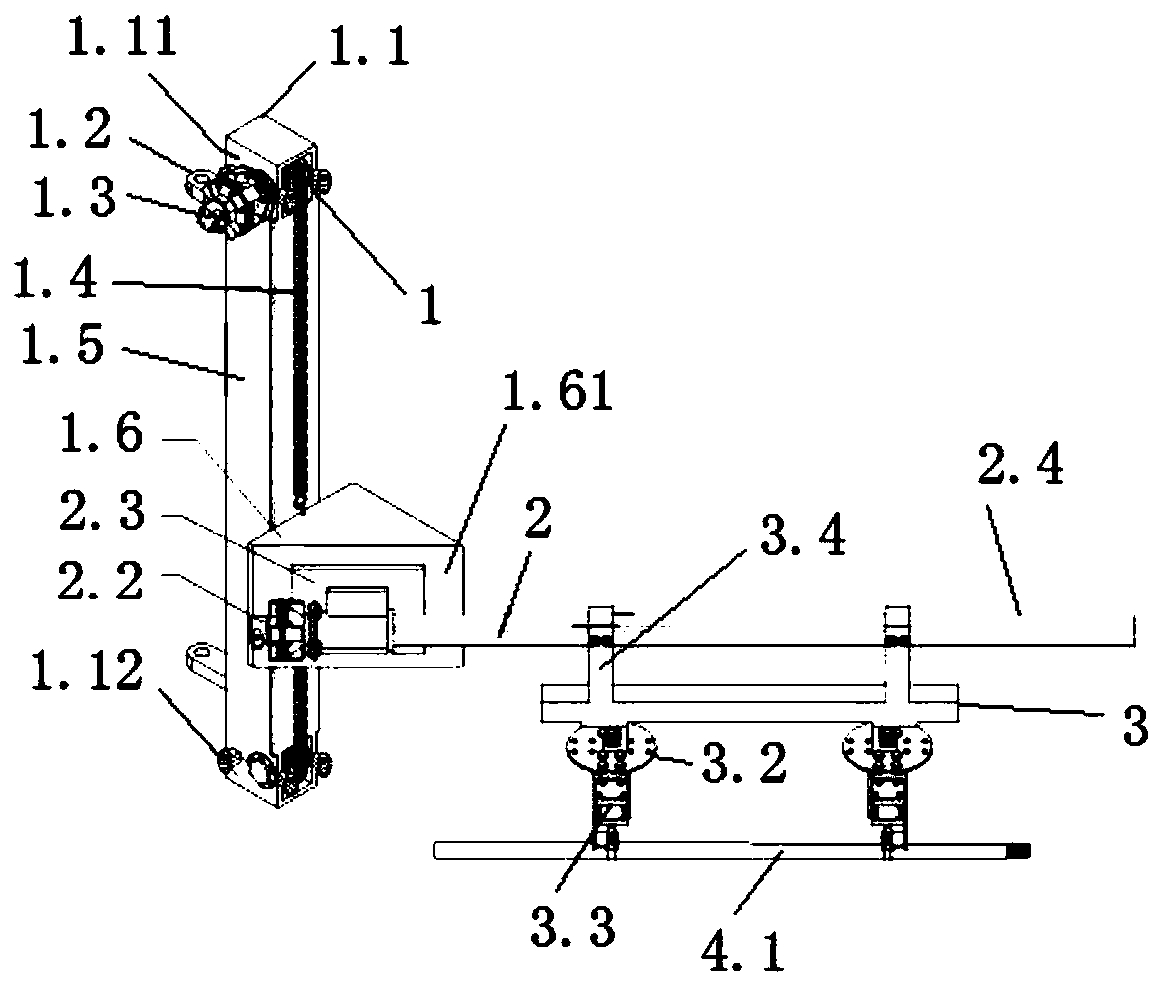

[0039] A kind of rod-taking mechanism for rock core sampling drilling rig, such as Figure 1-Figure 6 As shown, it includes a lifting mechanism 1, a grasping spindle attitude change mechanism 2, a manipulator grasping mechanism 3 and a rod storage box 4. The specific structure is as follows:

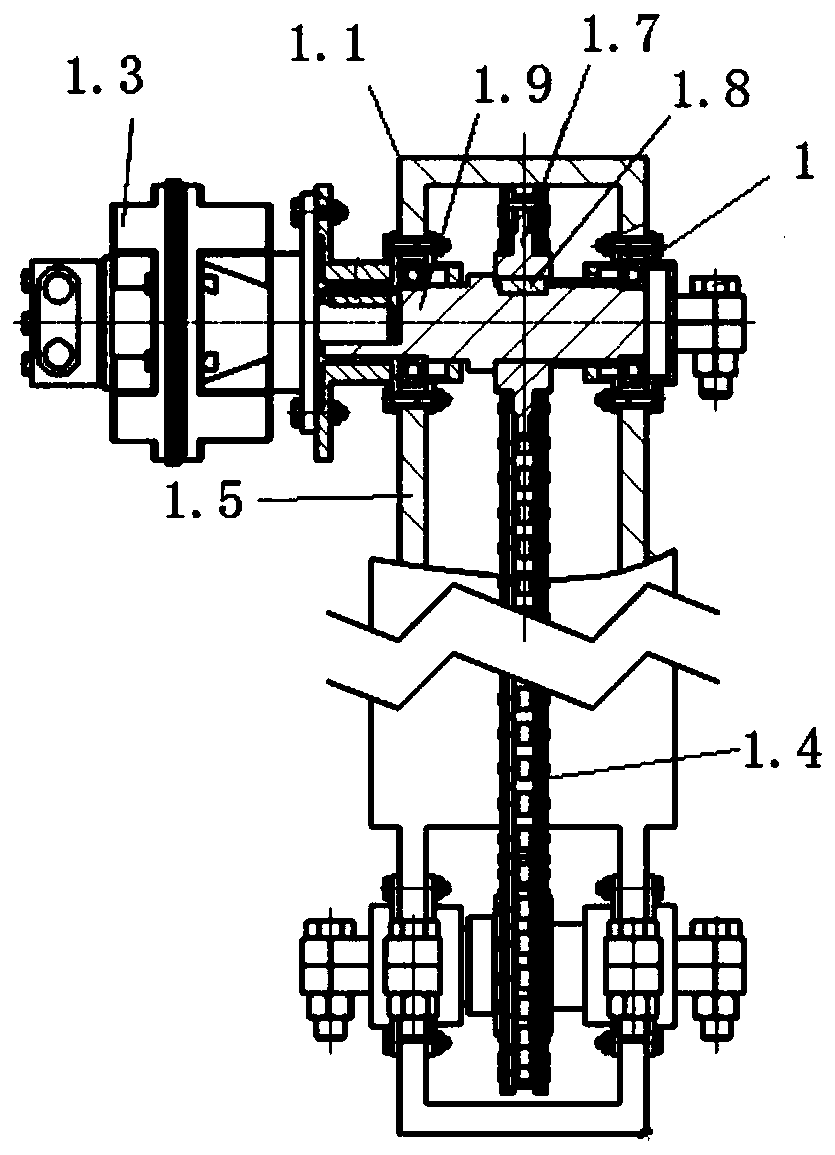

[0040] Such as Figure 1-3 As shown, the lifting mechanism 1 includes a guide rail mounting seat 1.1, a drill mast connection pair 1.2, a first power source 1.3, a transmission member 1.4, a guide rail 1.5, a moving slider 1.6, a roller sprocket 1.7, a round head flat key 1.8 and a drive shaft 1.9, the guide rail mounting seat 1.1 includes an upper guide rail cover 1.11 and a lower guide rail cover 1.12, both of which are provided with roller sprockets 1.7 inside; the rig mast connection pair 1.2 is used to connect the rod taking mechanism Installed on the core sampling drilling rig; the transmission part 1.4 is a chain, and the chain is sleeved on the two roller sprockets 1.7; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com