Drying and incineration vertical integrated sludge and oil sludge manure continuous treatment equipment

A vertical, sludge technology, used in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as lack of pre-drying process, and achieve significant energy saving, energy saving, and productivity promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in conjunction with the following examples.

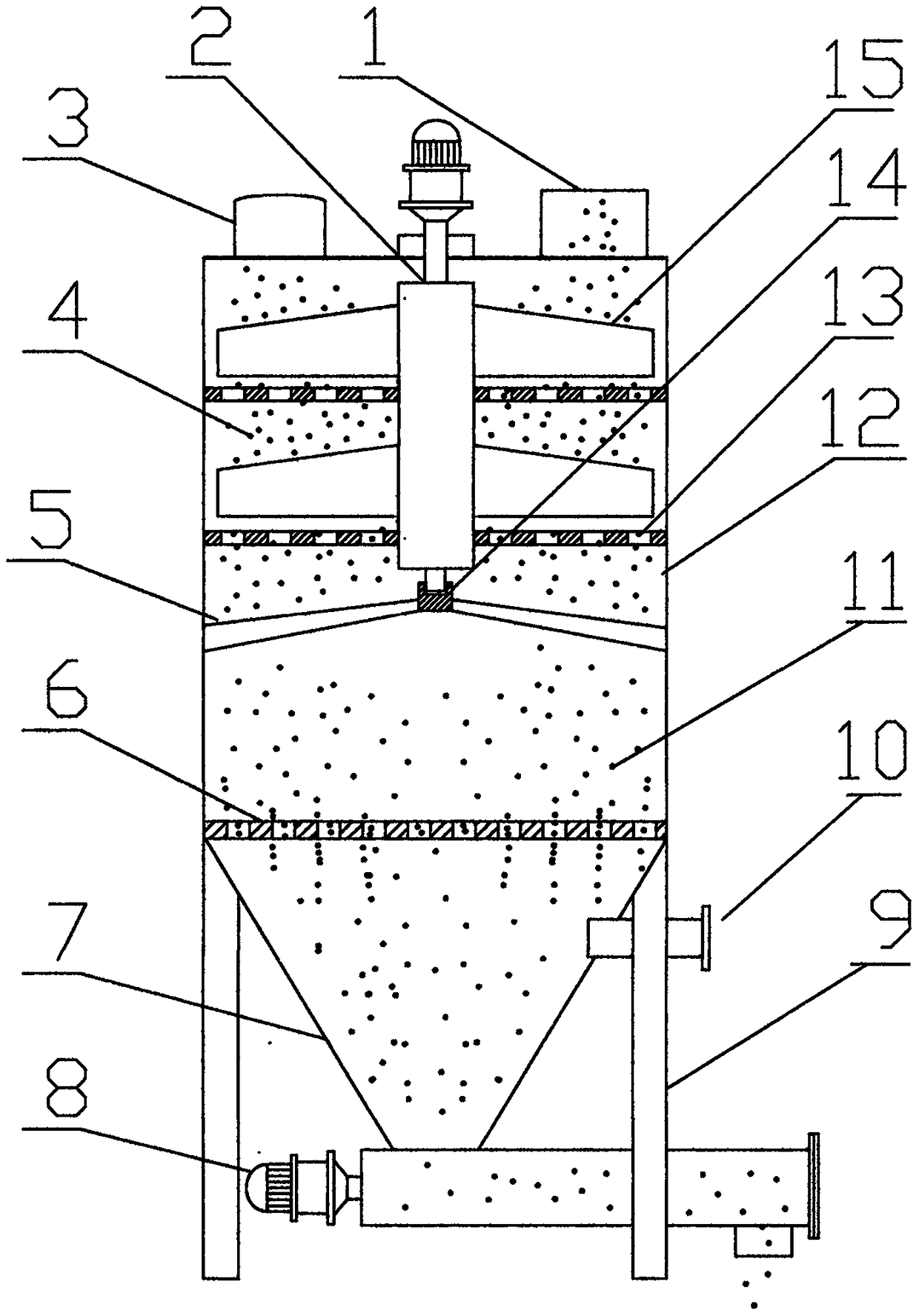

[0014] A vertical integrated continuous treatment of sludge, oil, sludge and manure equipment for drying and incineration, consisting of a feed inlet 1, a stirrer 2, an air outlet 3, a support 5, a furnace bar 6, a slag receiving hopper 7, and a slag discharger 8 , support 9, heating port 10, incineration chamber 11, drying chamber 12, blanking grid 13, groove 14, blade 15, wherein, the top of the drying chamber 12 is provided with an air outlet 3 and a feed inlet 1; The lower part of the drying chamber 12 is provided with a combustion chamber 11, and a support 5 is provided between the drying chamber 12 and the combustion chamber 11; the lower part of the combustion chamber 11 is provided with a grate 6; the lower part of the grate 6 is provided with a slag receiving bucket 7; A slag ejector 8 is provided at the bottom of the hopper 7; a heating port 10 is provided on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com