Testing device and method for permeability of uranium tailing and underlying rock-soil layer of uranium tailing pond

A testing device and permeability technology, which are applied in the field of uranium tailings pond safety engineering, can solve the problems of permeability testing of no uranium tailings and the underlying rock and soil layer and the variation law of permeability with time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

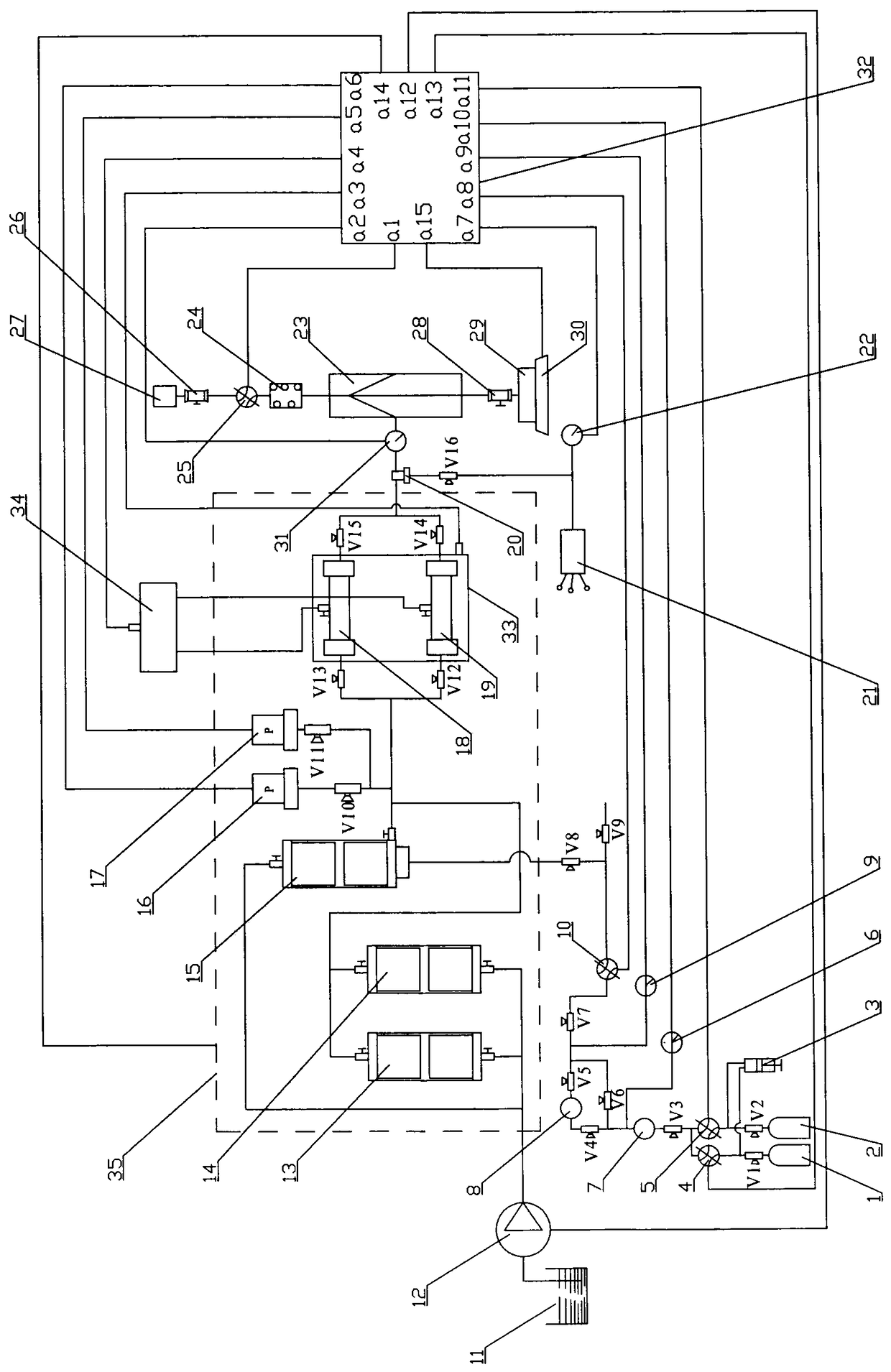

[0077] Embodiment 1: The uranium tailings of the uranium tailings pond and the permeability testing device of the underlying rock and soil layer, including a gas pressure regulating injection system, a liquid pressure regulating injection system, a pressure measurement system, an excitation system, a back pressure system, and a flow metering system , data collector 32 and incubator 35.

[0078] The gas pressure regulating injection system includes a carbon dioxide gas storage tank 1, a nitrogen gas storage tank 2, a booster pump 3, a first gas mass flow controller 4, a second gas mass flow controller 5, a third gas mass flow controller Device 10, digital display meter 6 of the first real-time pressure collector, digital display meter 9 of the second real-time pressure collector, high-pressure regulator valve 7, low-pressure regulator valve 8, and solenoid valves V1-V9.

[0079] The carbon dioxide gas storage tank 1 is connected to the inlet end of the first gas mass flow contr...

Embodiment 2

[0107] Embodiment 2. The method of testing the permeability of uranium tailings and the underlying rock and soil layer by using the uranium tailings pond and the permeability test device of the underlying rock and soil layer in the uranium tailings pond. This embodiment uses gas-liquid mixing to measure the underlying rock and soil layer Permeability and uranium tailings permeability, the specific steps are as follows:

[0108] A. Preparation before the test

[0109] A1. Remove the rock-soil sample holding device 18 and the uranium tailings filling device 19 from the vibration excitation device 33 in the test device, and put the obtained standard-sized underlying rock-soil layer sample into the rock-soil sample holding device 18 , put the uranium tailings into the uranium tailings filling device 19 in layers, and compact the uranium tailings to the density value of the in-situ uranium tailings body, and fill the rock soil sample holder 18 and the uranium tailings after filling...

Embodiment 3

[0126] Embodiment 3. The method of testing the permeability of uranium tailings and the underlying rock and soil layer by using the uranium tailings pond and the permeability test device of the underlying rock and soil layer in the uranium tailings pond. In this embodiment, a single mixed gas is used to measure the underlying rock and soil layer Permeability and uranium tailings permeability, the specific steps are as follows:

[0127] A. Preparation before the test

[0128] A1. Remove the rock-soil sample holding device 18 and the uranium tailings filling device 19 from the vibration excitation device 33 in the test device, and put the obtained standard-sized underlying rock-soil layer sample into the rock-soil sample holding device 18 , put the uranium tailings into the uranium tailings filling device 19 in layers, and compact the uranium tailings to the density value of the in-situ uranium tailings body, and fill the rock soil sample holder 18 and the uranium tailings after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com