Lens defect detection device

A defect detection and lens technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as difficulty in guaranteeing stability and reliability, inability to quantify lens defects, and inability to strictly match production speeds, etc. Achieve the effect of reducing labor intensity and enterprise production cost, good practicability and scalability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

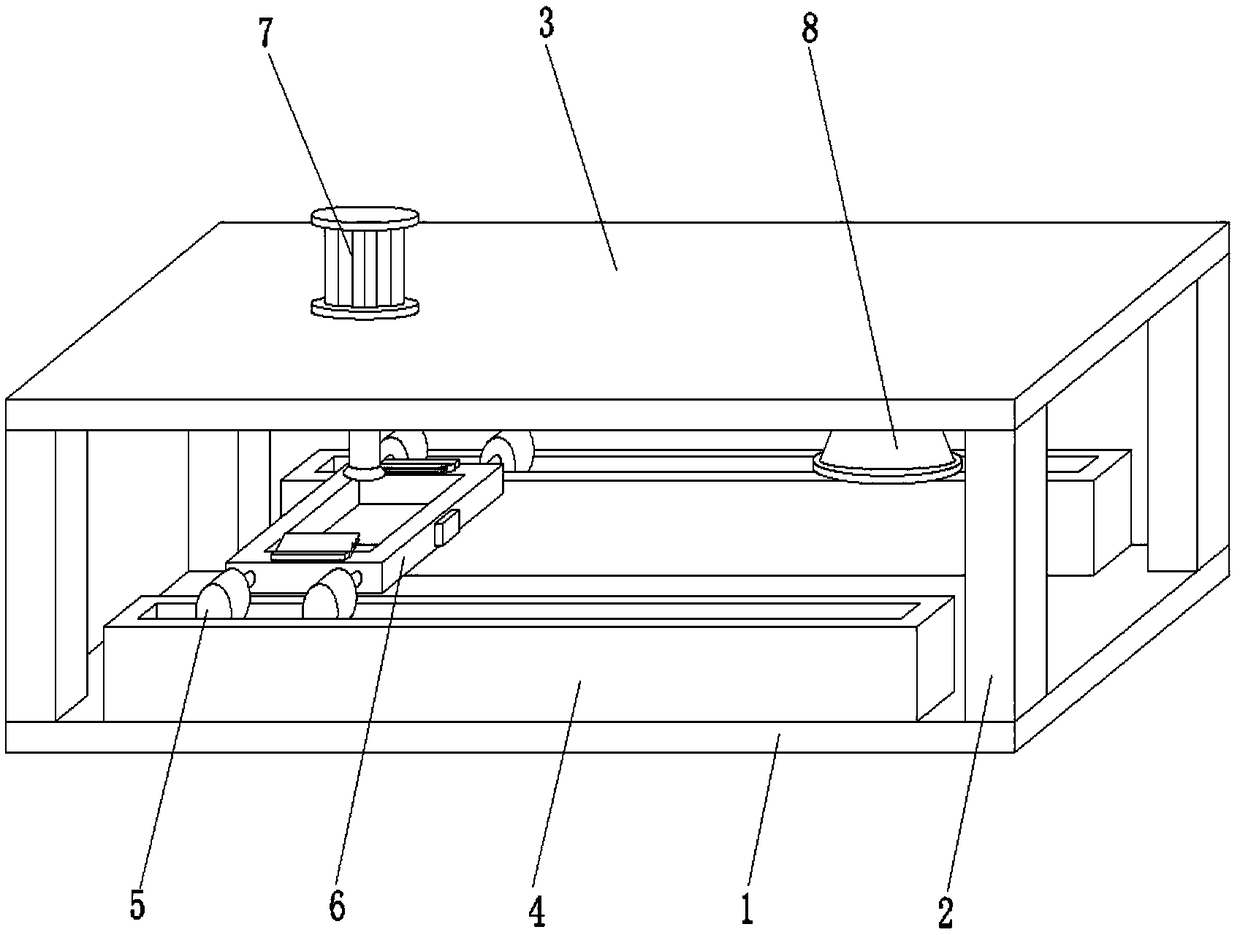

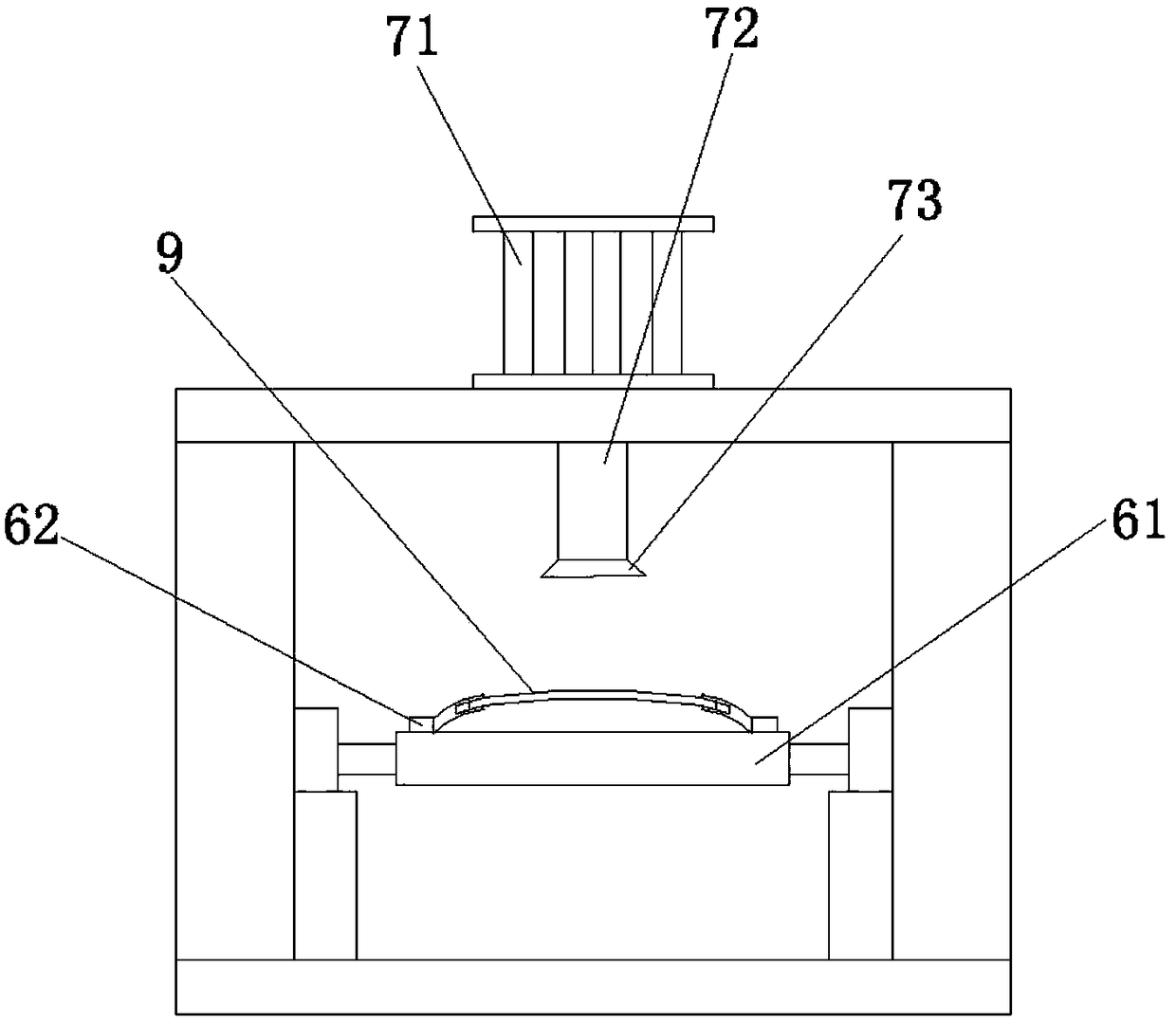

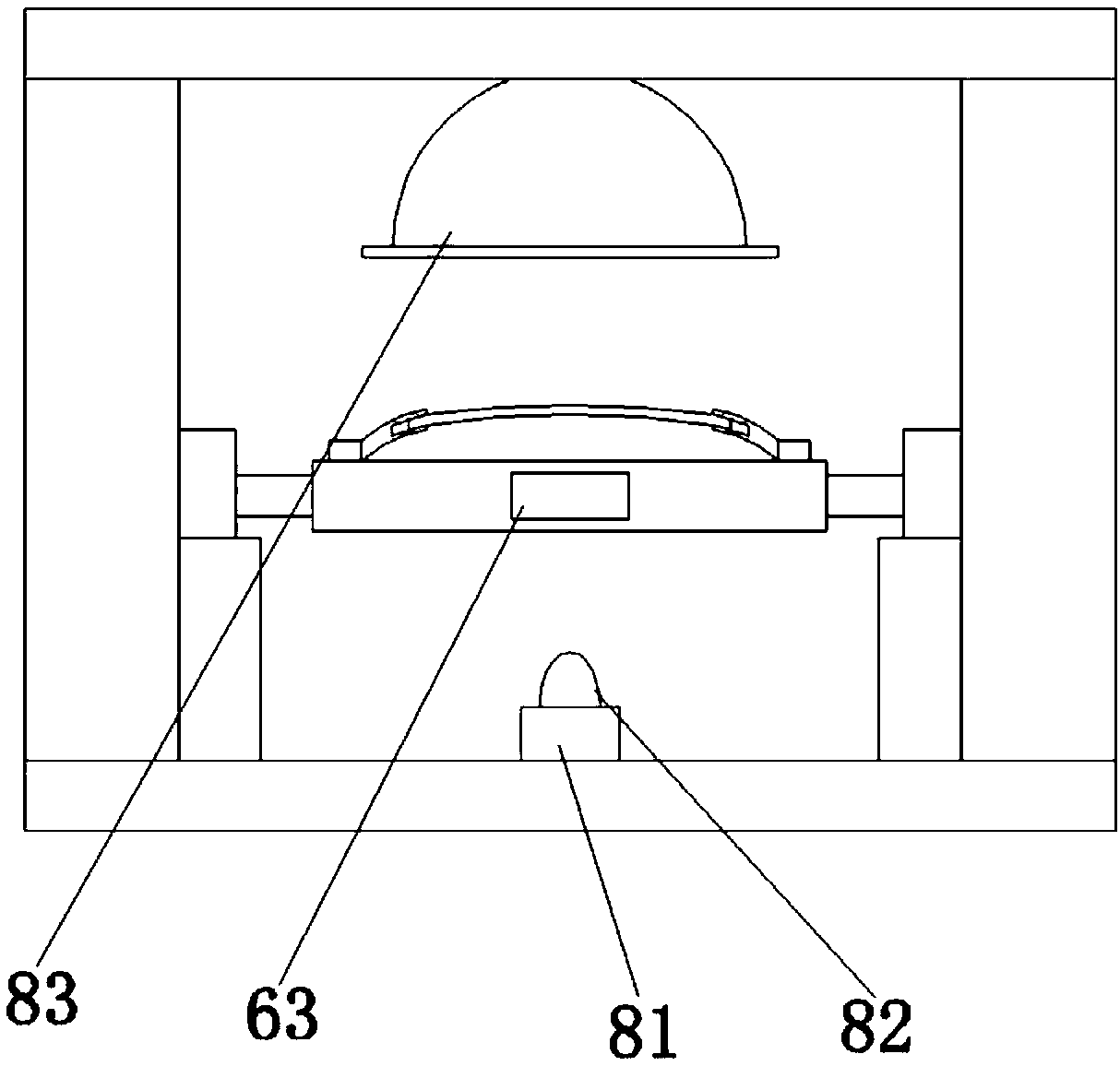

[0024] combine figure 1 , a lens defect detection device, including a device body, the device body is connected to an external PLC industrial computer for communication, the device body includes a base 1, a top plate 3, and a support column 2 arranged between the base 1 and the top plate 3, the base 1 The upper surface is provided with a pair of slide rails 4 along the long side direction, above the slide rails 4 is provided with a moving mechanism 5, the moving mechanism 5 is connected with the bearing plate 6, and the moving mechanism 5 is arranged on the outside of the bearing plate 6 along the slide rail 4 direction, One end of the top plate 3 is provided with a pneumatic dust blowing mechanism 7, and the other end of the top plate 3 is provided with an optical detection mechanism 8. Both the pneumatic dust blowing mechanism 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com