Efficient low-profile wide-axis ratio bandwidth large-scale circularly-polarized array antenna

A technology with axial ratio bandwidth and low profile is applied in the field of antenna arrays to achieve the effects of simple manufacture, low profile and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

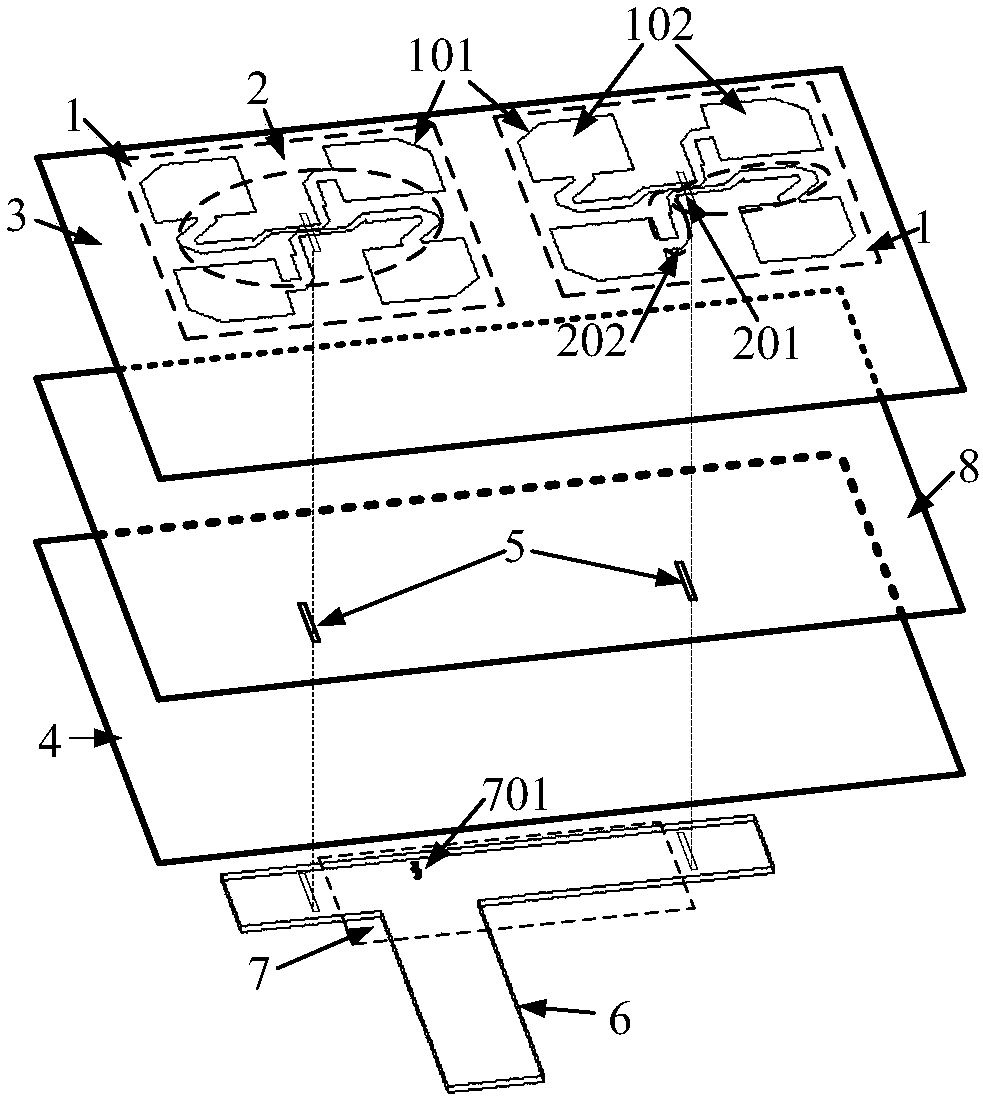

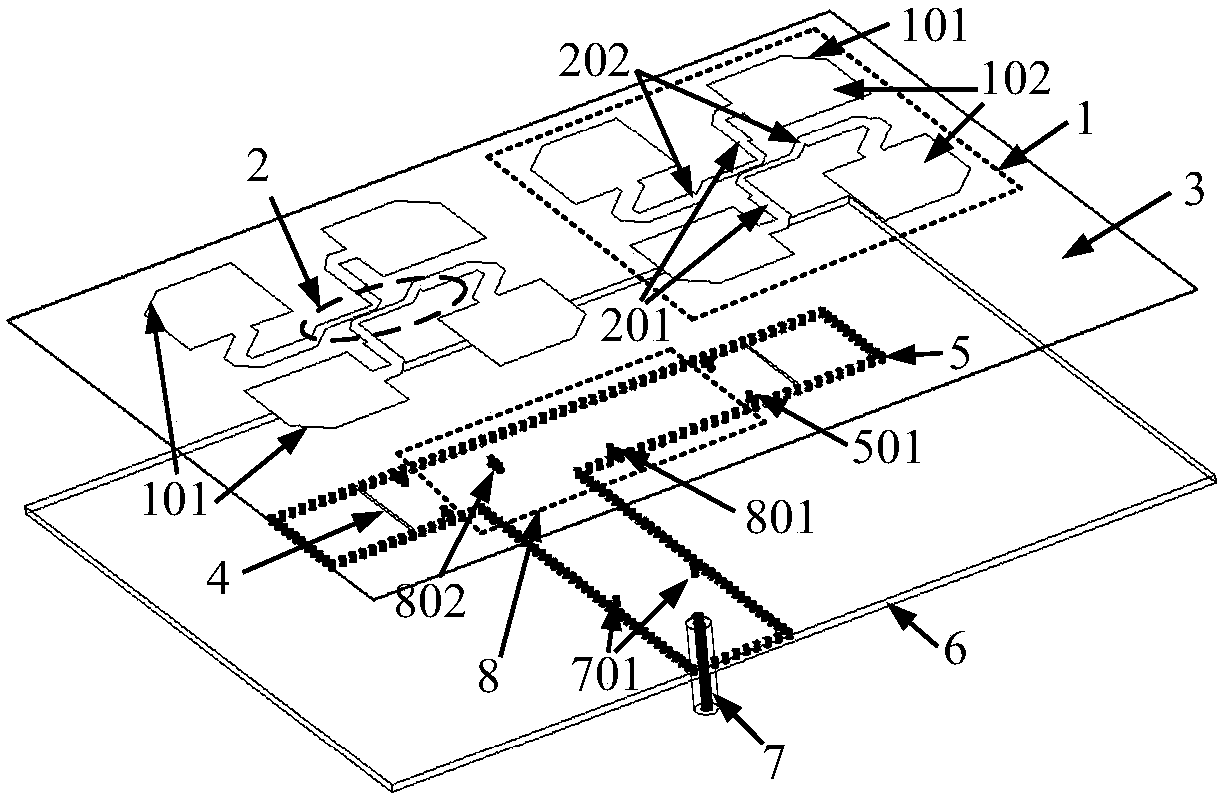

[0031] The 2×4 wide-axis ratio bandwidth planar circularly polarized antenna array of this embodiment is as follows figure 2 As shown, the radiation patch-102 with cut corners-101 and the sequentially rotating microstrip feed network-2 are printed on the film-3, and every four rectangular radiation patches-102 with cut corners and a sequentially rotated microstrip feed network -2 constitutes a circular polarized sub-array-1; the SIW feed network-5 is constructed on the dielectric board-6 with the short-circuit via-501 array using traditional PCB technology, and the circle is excited through the rectangular slot-4 etched on the SIW Polarization sub-array-1; SIW equal-amplitude anti-phase power divider-8 excites two circular polarimetric sub-arrays to ensure equal-amplitude and in-phase excitation of 2×4 radiating patches. The via-501 adjusts the matching characteristics of the circularly polarized subarray-1, and the vias-801 and 802 adjust the matching characteristics and pow...

Embodiment 2

[0034] The 6×16 wide-axis ratio bandwidth planar circularly polarized antenna array of this embodiment is as follows Figure 7 As shown, 6×16 radiating patches-102 with cut corners-101 and 3×8 microstrip feeding networks-2 are printed on the film-3, and every four radiating patches are rotated by 90º in sequence, and one The microstrip feed network-2 constitutes a circularly polarized sub-array-1. The SIW feed network-5 is constructed on the dielectric board-6 by using the traditional PCB process with the array of short-circuit vias-501, and the circularly polarized sub-array-1 is excited through the rectangular slit-4 etched on the SIW; every two sub-arrays- 1 Use a SIW equal-amplitude inverting power divider-8 excitation to ensure equal-amplitude and in-phase excitation for 2×4 radiating patches. It is further expanded through the SIW equal-amplitude equal-phase power divider-9 and the one-to-two equal-phase power divider-10, and finally feeds the entire antenna array throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com