A low temperature heating cigarette with mint flavor

A mint and flavor technology, applied in tobacco, e-liquid filter, manufacturing cigars, etc., can solve problems affecting consumers' consumption experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

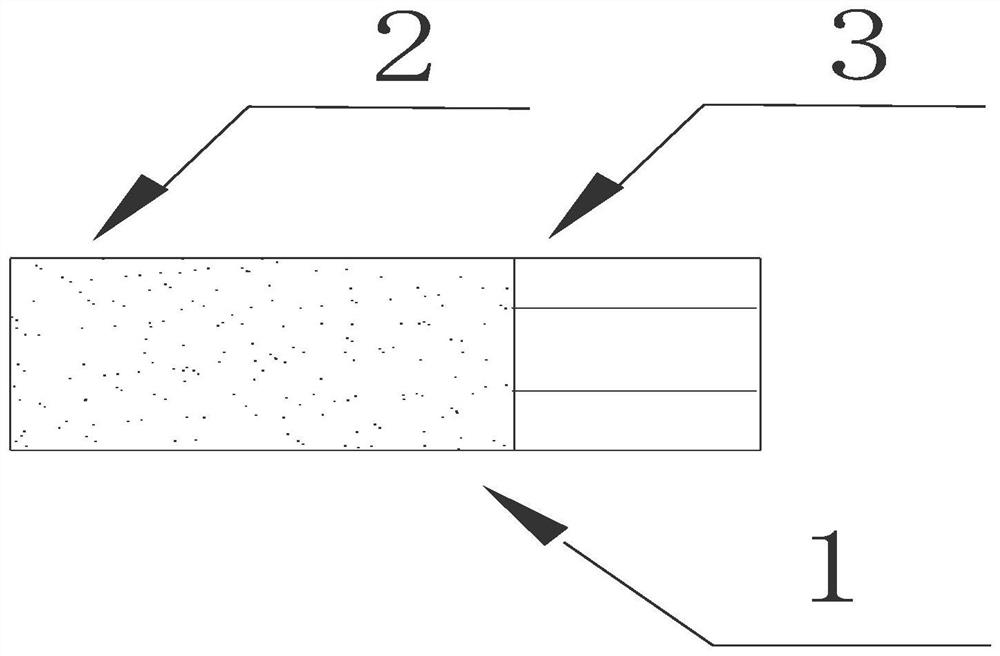

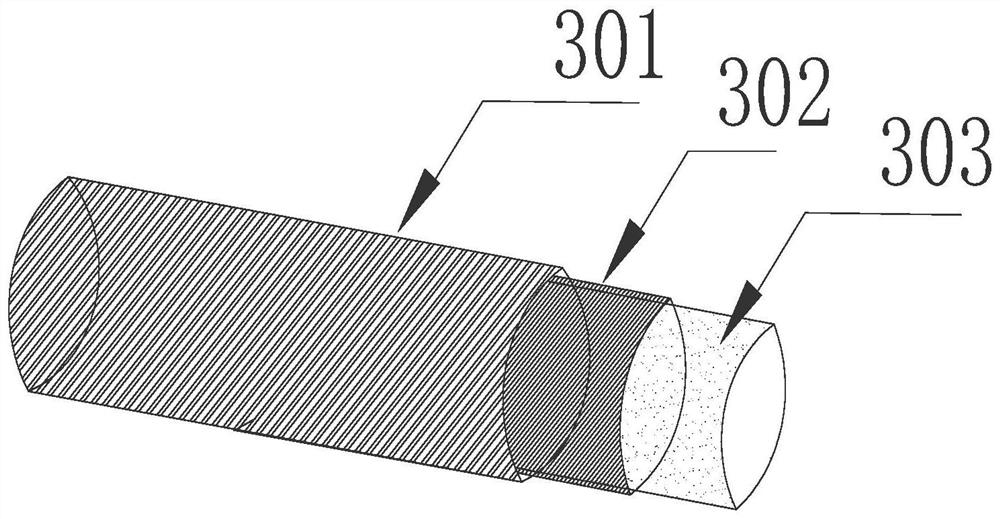

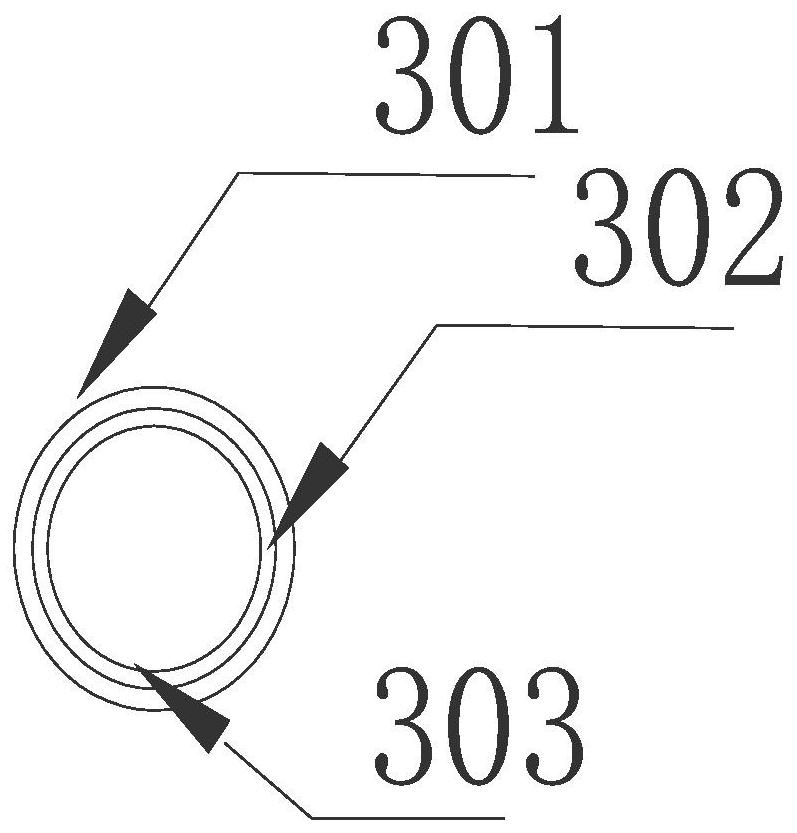

[0028] Such as Figure 1-3 As shown, a low-temperature heating cigarette 1 with a mint flavor includes: an atomizing base section 2, which is used to generate aerosol after heating; a cooling nozzle rod 3, which is used to reduce the temperature of the smoke entering the oral cavity, and its structure is a hollow cylinder The tubular structure is composed of a shell 301, an adhesive layer 302, and a cooling layer 303. The adhesive layer 302 bonds the shell 301 and the cooling layer 303 together.

[0029] The adhesive layer contains heat-sensitive microcapsules, which are used to change the bonding state between the shell and the cooling layer during the suction process, and improve the cooling efficiency of the smoke. The response temperature of the heat-sensitive microcapsules is about 60°C. After reaching the response temperature, the microcapsules begin to release the dissolving agent and tobacco flavor; the dissolving agent is selected from olive oil, and the mint-containi...

Embodiment 2

[0035] Such as Figure 1-3 As shown, a low-temperature heating cigarette 1 with a mint flavor includes: an atomizing base section 2, which is used to generate aerosol after heating; a cooling nozzle rod 3, which is used to reduce the temperature of the smoke entering the oral cavity, and its structure is a hollow cylinder The tubular structure is composed of a shell 301, an adhesive layer 302, and a cooling layer 303.

[0036] The adhesive layer contains heat-sensitive microcapsules, which are used to change the bonding state between the shell and the cooling layer during the suction process, and improve the cooling efficiency of the smoke. The response temperature of the heat-sensitive microcapsules is about 60°C. After reaching the response temperature, the microcapsules begin to release a dissolving agent; , peppermint oil is composed according to 0.8:0.7:1, and the heat-sensitive microcapsules account for 20% of the total amount of the adhesive, so that enough dissolving ...

Embodiment 3

[0042] Such as Figure 1-3 As shown, a low-temperature heating cigarette 1 with a mint flavor includes: an atomizing base section 2, which is used to generate aerosol after heating; a cooling nozzle rod 3, which is used to reduce the temperature of the smoke entering the oral cavity, and its structure is a hollow cylinder The tubular structure is composed of a shell 301, an adhesive layer 302, and a cooling layer 303.

[0043] The adhesive layer contains heat-sensitive microcapsules, which are used to change the bonding state between the shell and the cooling layer during the suction process, and improve the cooling efficiency of the smoke. The response temperature of the heat-sensitive microcapsules is about 60°C. After reaching the response temperature, the microcapsules begin to release a dissolving agent; the dissolving agent is selected from olive oil, and the mint-containing tobacco essence is composed of mint oil. The heat-sensitive microcapsules account for 12% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com