Internal circulation controlled flat type static-state powder concentrator, internal circulation controlled powder selecting system and powder selecting technological process of internal circulation controlled powder selecting system

A technology of powder classifier and internal circulation, which is applied in the direction of separating solids from solids by air flow, solid separation, grain treatment, etc. It can solve the problems of low overall efficiency of sorting and grinding, high construction cost, etc., and achieve extended material Dwell time, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

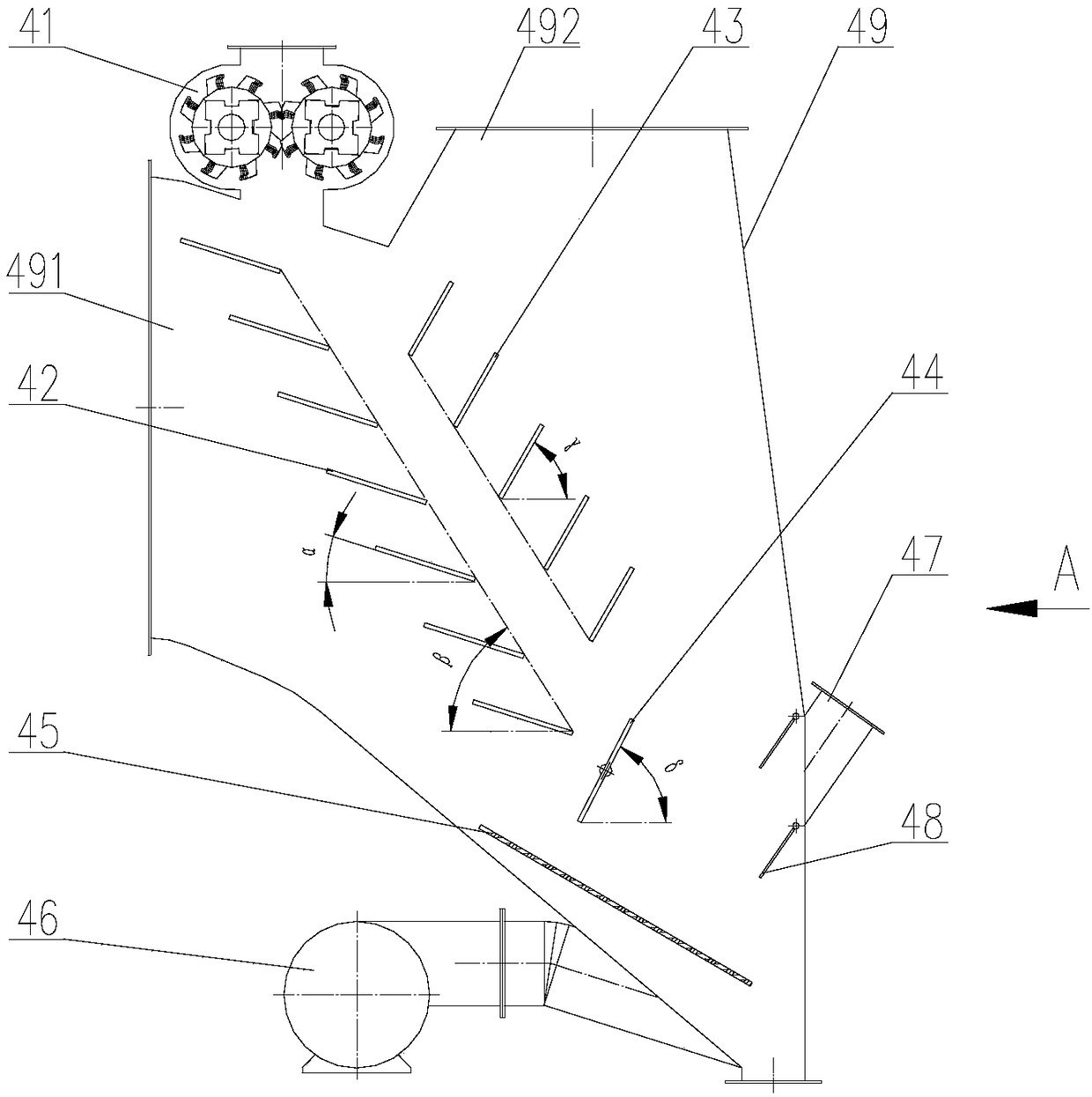

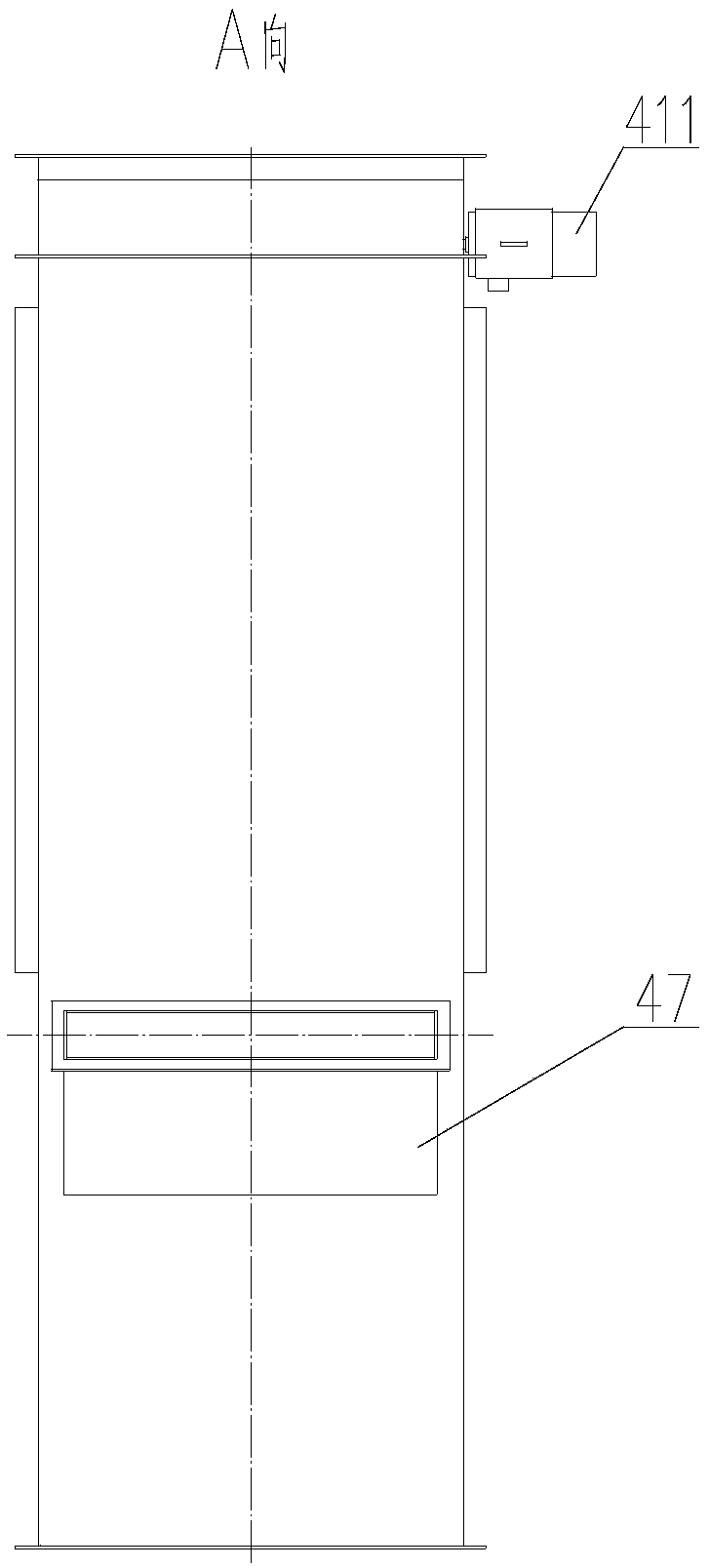

[0064] Such as Figure 7b , the difference between this embodiment and Embodiment 1 is the structure of the lifting device 48, the structure of the lifting device 48 is an impeller type, and the lifting device 48 includes a lifting shaft 482, a lifting impeller 483 and a lifting The blade 484 and the lifting shaft 482 are installed inside the casing 49 and the position corresponds to the internal circulation interface 47 . The lifting impeller 483 is fitted on the lifting shaft 482 . Several blades 484 are evenly distributed on the lifting impeller 483 . Driven by external force, the lifting device shaft 48 drives the lifting blade 484 to rotate towards the direction of the coarse powder entering the inner circulation interface 47 to disperse the coarse powder. The impeller is designed for frequency conversion and speed regulation, so the coarse powder can be scattered in different flow field areas according to the working conditions to form a controllable internal circulati...

Embodiment 3

[0066] Such as Figure 7c , The difference between this embodiment and Embodiment 1 is the structure of the material raising device 48, and the structure of the material raising device 48 is a material spreading box type. An extension plate 485 is designed on the upper and lower sides of the inner circulation interface 47, and a wear-resistant lining 486 is coated on the lower extension plate. The coarse powder returned by the fine powder separator 5 enters the flow field area of the powder separator along the wear-resistant lining 25, and a single or multiple nozzles 487 are arranged below the lower extension plate. The nozzle 487 sprays air through compressed air or a blower device and sprays and cleans the fine powder contained in the coarse powder entering the internal flow field area, so as to achieve the purpose of controlling the internal circulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com