Fully automatic edge sealing and punching production line of sheet material and production method

An automatic sealing and sheet metal technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of large site area demand, low production efficiency, high labor intensity of employees, etc., to improve processing efficiency, avoid collision risks, and save labor costs. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

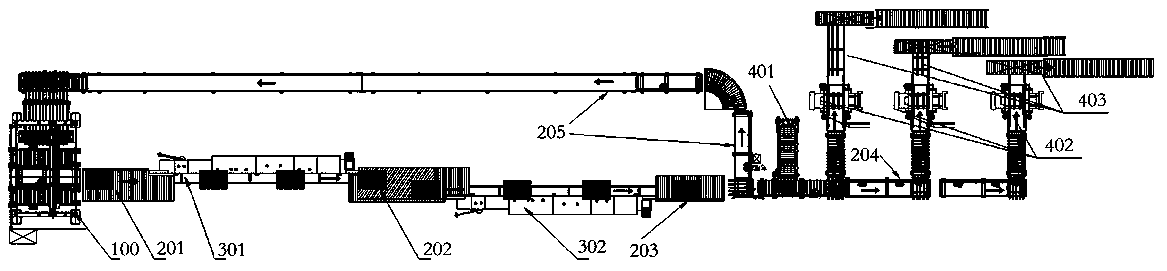

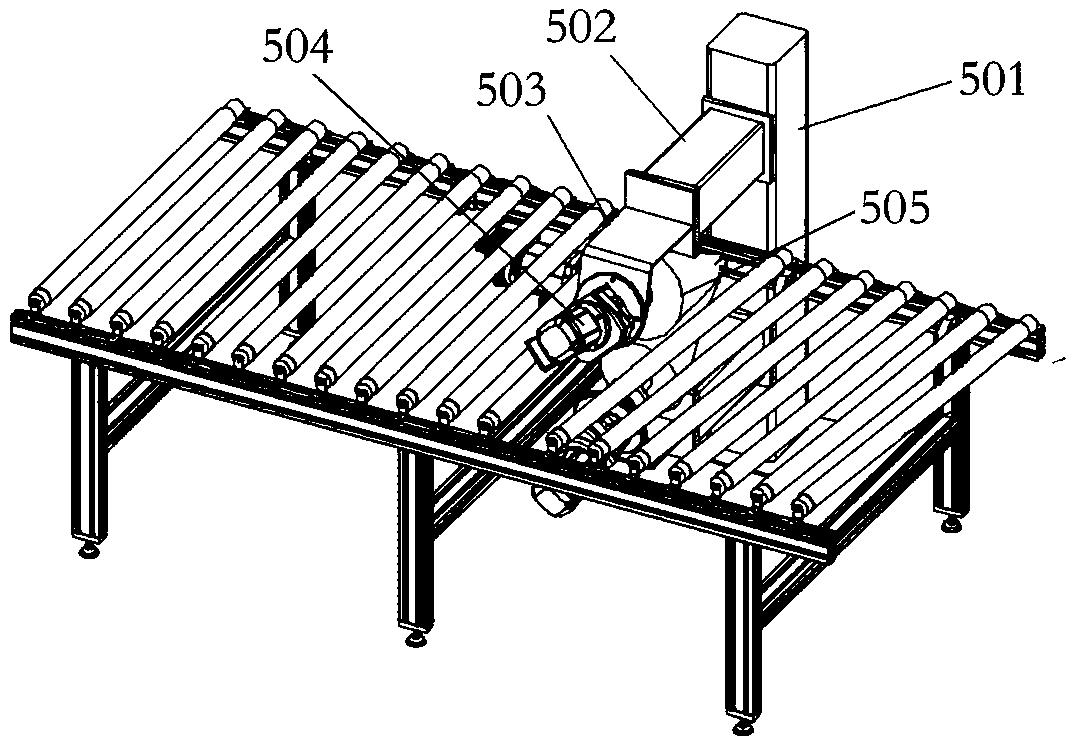

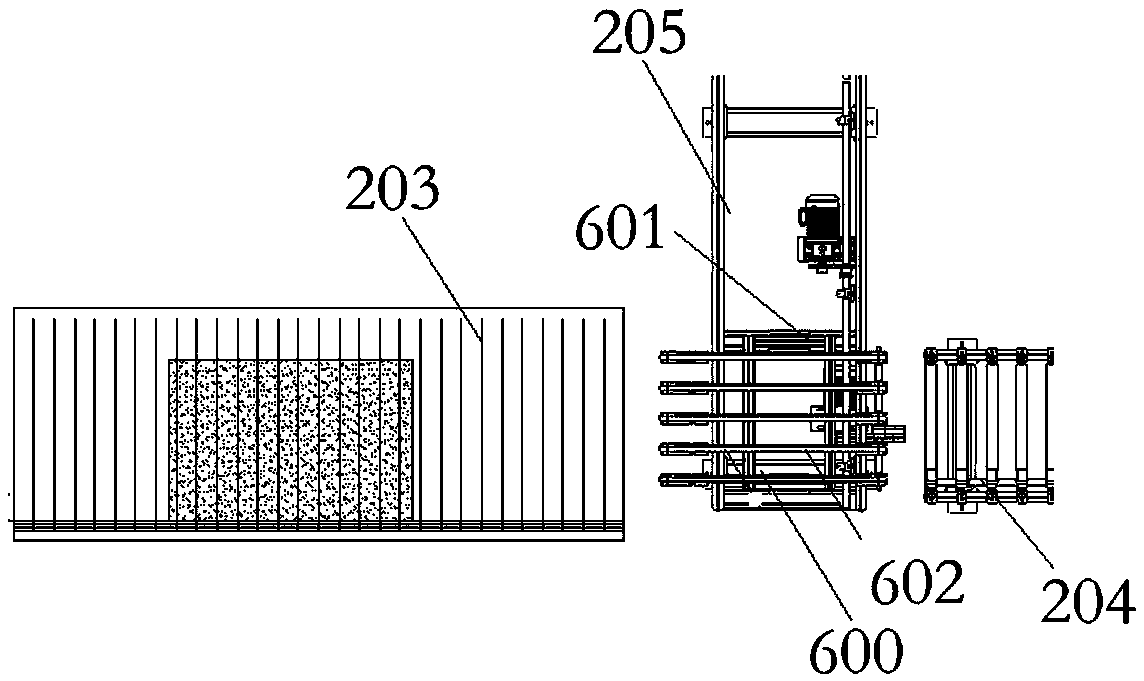

[0052]This embodiment is a preferred embodiment, which mainly includes an automatic feeding system 100, an edge banding system, an automatic drilling and arranging system, a power transmission system and a judgment control system. The power transmission system includes a first power transmission line 201 , a second power transmission line 202 , a third power transmission line 203 , a fourth power transmission line 204 and a return transmission line 205 . The automatic feeding system 100 is used to feed the edge banding system, and it transports the plates to the edge banding system through the first power transmission line 201. In this embodiment, the automatic feeding system 100 uses a gantry robot. The edge banding system includes a left-hand edge bander 301 and a right-hand edge bander 302, the left-hand edge bander 301 and the right-hand edge bander 302 are connected through the second power transmission line 202; The third power transmission line 203 . The automatic dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com