Flat-bottom diamond raw material forming device

A forming device and flat-bottom drill technology, which is applied in the field of imitation drill production, can solve the problems of large air flow space, unfavorable economic benefits, and energy consumption, and achieve the effects of small air flow space, reduced processing procedures, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

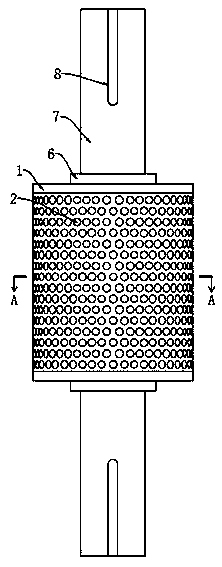

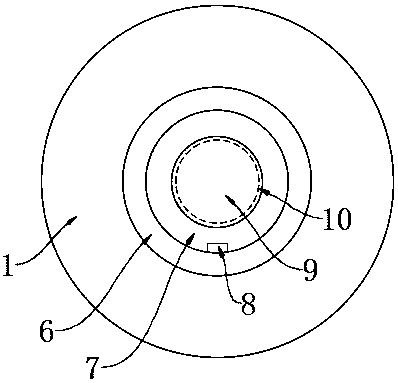

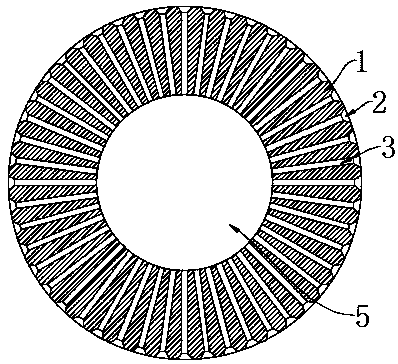

[0026] see Figure 1~3 , in the embodiment of the present invention, a flat-bottomed drill raw material forming device includes a plastic-absorbing roller 1, and the side wall of the plastic-absorbing roller 1 is uniformly provided with several forming grooves 2, and the shape of the forming groove 2 matches the shape of the flat-bottomed drill, specifically There is no requirement, and it can be set according to the needs. For example, if there are eight star surfaces on the crown of the flat-bottomed drill, the forming groove 2 is provided with eight edges; the axial position of the blister roller 1 is provided with a first air flow channel 5; the forming The inner end of the groove 2 is provided with a ventilation hole 3 communicated with the first airflow passage 5; the upper and lower sides of the blister roller 1 are also respectively provided with a rotating shaft 7, and the rotating shaft 7 is fixedly connected with a connection plate 6 towards the end face of the blist...

Embodiment 2

[0028] see Figure 4~5 , on the basis of Example 1, the side wall of the plastic-absorbing roller 1 is located outside the forming groove 2 and is also fixedly provided with an annular boss 4 cooperating with the forming groove 2, and the outer ends of the annular boss 4 are flush; the plastic-absorbing roller 1 The side wall has a certain radian, so that the bottom of the flat-bottomed drill obtained by processing is not flat enough. By setting the annular boss 4, the bottom of the flat-bottomed drill blank formed after shoveling off the excess material is directly flat, and the quality is better. The flat-bottomed drill does not need subsequent processing and grinding. Reduce processing procedures and avoid defective products.

Embodiment 3

[0030] A kind of imitation diamond production equipment, comprises above-mentioned flat bottom drill raw material forming device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com