A CNC woodworking engraving machine

A technology of engraving machine and CNC machine tool, applied in engraving, decorative arts and other directions, can solve the problems of complicated fixing operation steps and poor wood fixing effect, and achieve the effects of not easy to shake, stable use and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

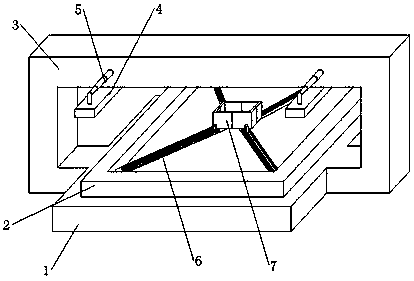

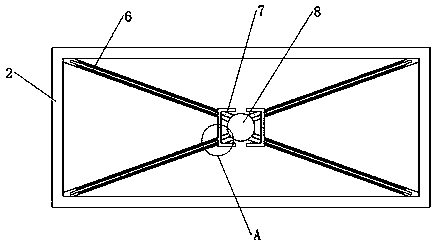

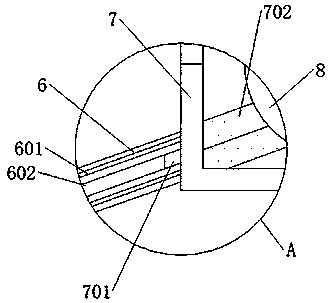

[0028] see figure 1 to attach Figure 8 , a CNC woodworking engraving machine, comprising: a CNC machine base 1, a support block 2, a frame body 3, a slide plate 4, a slide plate 401, a vertical guide pipe 402, a horizontal guide water pipe 403, a hydraulic telescopic rod 404, a sliding Slot 405, card plate 406, micro motor 407, turntable 4071, cutter 4072, telescopic rod 5, slide rail 6, side slide slot 601, positive slide slot 602, spring column 603, receiving plate 604, through hole 605, auxiliary moving ball 606, ball 607, baffle plate 7, slider 701, bottom wheel 7011, connection hole 7012, bottom plate 7013, dustproof cloth 702 and support block 8, support block 2 is welded in the middle part of the top of CNC machine base 1, CNC machine base 1 The frame body 3 is welded on the left and right sides, the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com