Sterile plastic bottle embryo

A technology of aseptic plastics and preforms, which is applied in the field of plastic packaging bottles, can solve the problems that the antibacterial ability is greatly affected by the environment, affects the quality of medicines or food, and has poor antibacterial effects. Capacitance, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

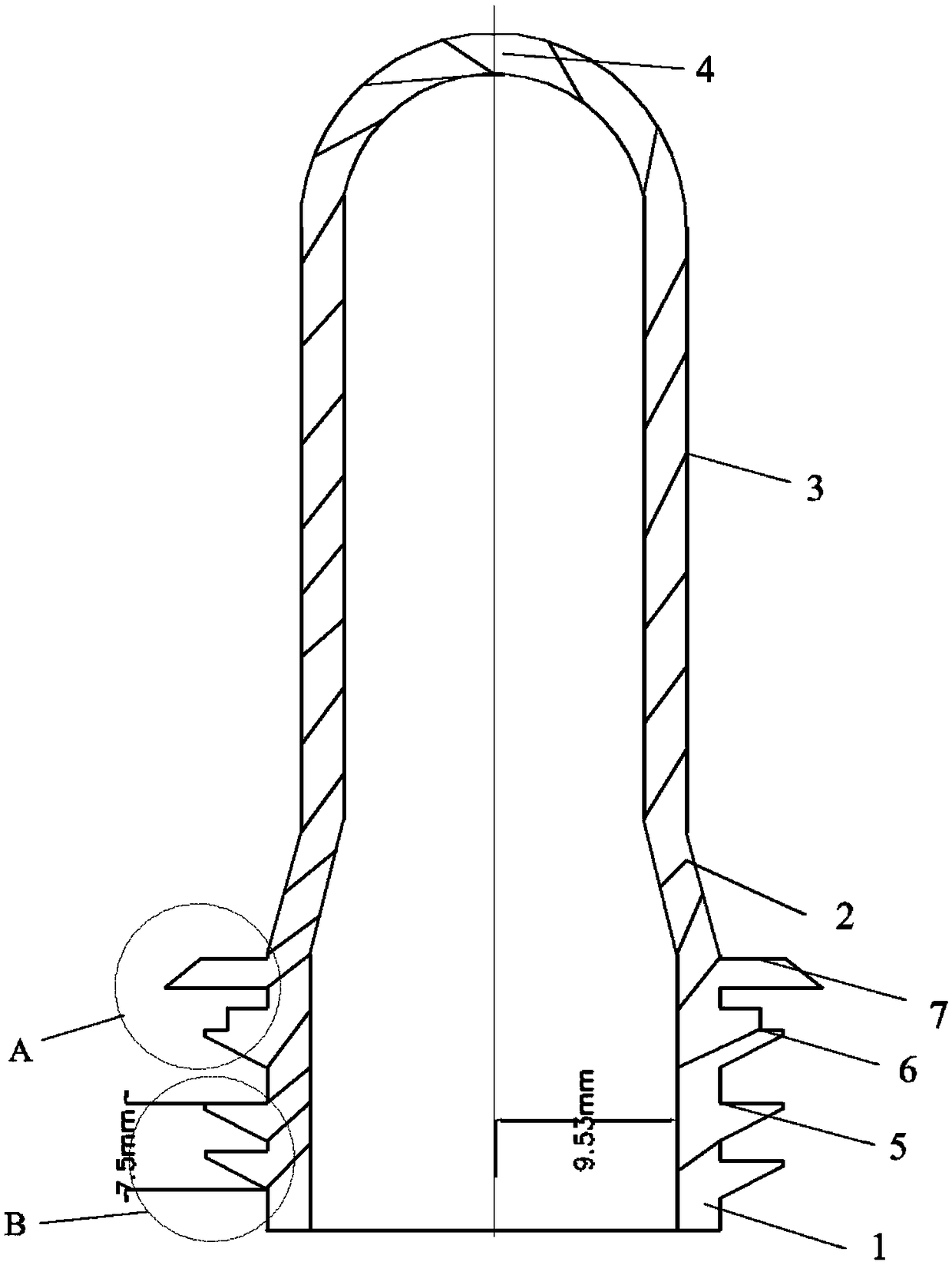

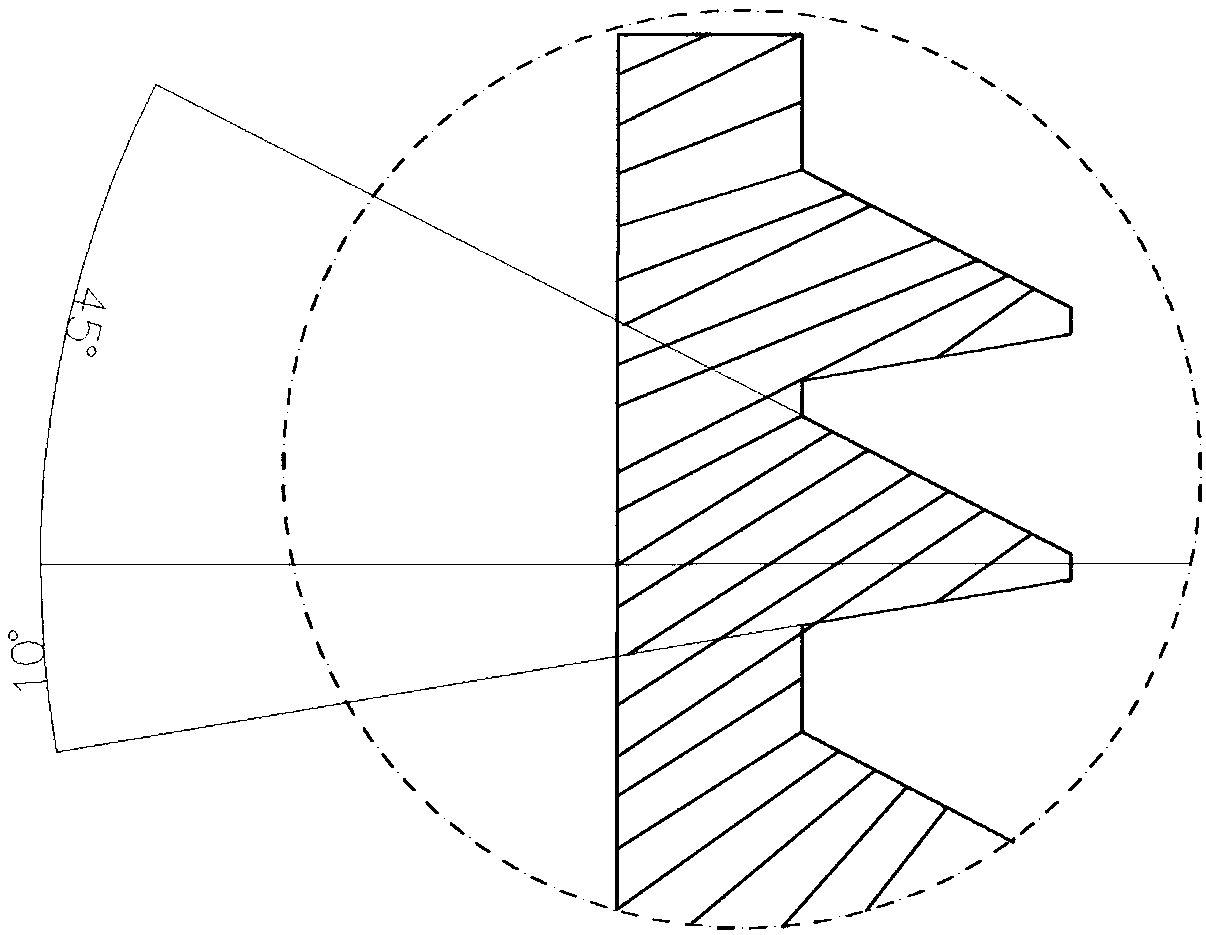

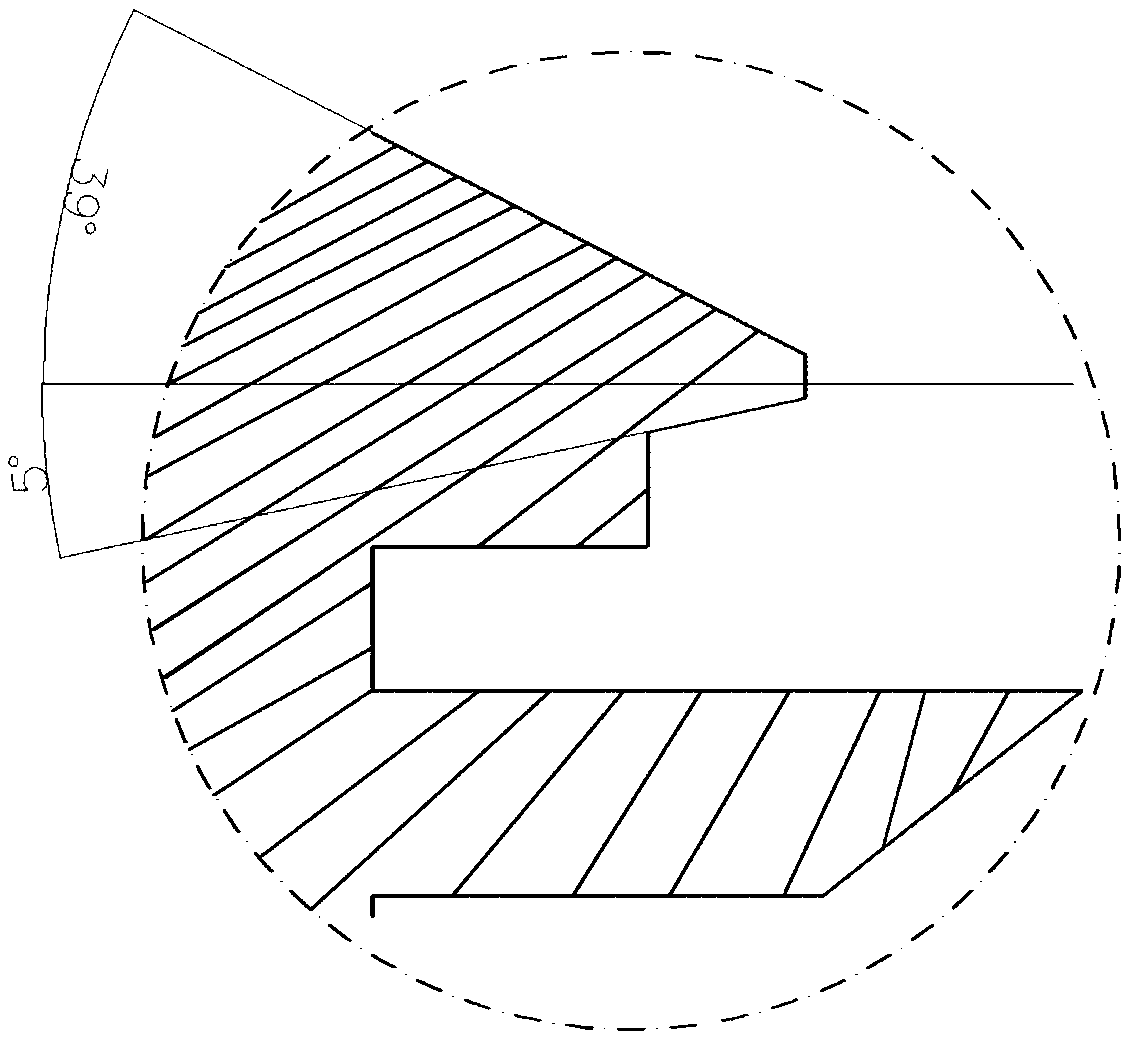

[0052] A sterile plastic preform, comprising a preform mouth 1, a preform neck 2, a preform body 3 and a preform bottom 4, the four are integrally formed by injection molding, the preform mouth 1, the preform neck 2, the preform The preform body 3 and the preform bottom 4 are integrally formed by injection molding. There is a thread 5 on the outside of the preform mouth 1, the bevel angle of the cut surface of the thread 5 is 45°, and the bevel angle of the cut surface is 10°.

[0053] Further, the preform bottom 4 is arc-shaped and connected with the preform body 3 in a straight line, and the preform body 3 passes through the preform neck 2 and the preform mouth 1 are connected in a streamlined shape; the thread 5 is a discontinuous thread 5 with a fracture, in a rising and spiraling state, the angle between the fractures is 47°, the thread height is 7.5mm, and the upper surface and the lower surface are in a straight line Transition; the radius of the preform opening 1 is 9....

Embodiment 2

[0062] The difference from Example 1 is that the ratio of the thickness of the preform body 3 to the thickness of the preform bottom 4 is 1.2:1.

Embodiment 3

[0064] The difference from Example 1 is that the ratio of the thickness of the preform body 3 to the thickness of the preform bottom 4 is 1.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com