Novel antibacterial anti-radiation silver infiltrating solid fiber fabric and preparation method thereof

A technology of anti-radiation and antibacterial silver, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of unstable conductivity, no oxidation resistance, no friction resistance, etc., to achieve high protection coefficient, good elasticity and strength, density big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

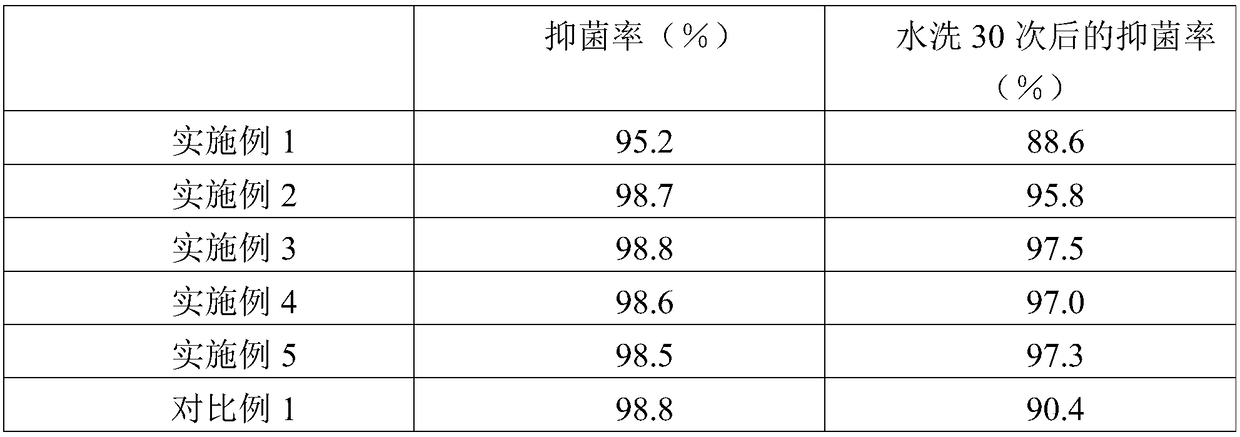

Examples

Embodiment 1

[0030] A preparation method for a novel antibacterial and anti-radiation silver-impregnated fiber fabric, comprising the following steps:

[0031] (1) Immerse the fiber fabric in the antibacterial silver solution, the immersion temperature is 30°C, the immersion time is 30 minutes, the bath ratio is 1:5g / g, and then the fiber fabric is dried at 45°C;

[0032] (2) Immerse the fiber fabric in step (1) in the water-resistant finishing solution, the immersion temperature is 55°C, the immersion time is 30 minutes, the bath ratio is 1:3g / g, and then the fiber fabric is dried at 50°C to obtain New antibacterial anti-radiation silver impregnated fiber fabric.

[0033] The antibacterial silver solution comprises the following components by weight: 5 parts of silver antibacterial agent, 6 parts of cetyltrimethylammonium bromide, 2 parts of guar gum, 7 parts of sodium dodecylbenzenesulfonate , 1000 parts of water. The preparation method of the antibacterial silver solution is as follow...

Embodiment 2

[0037] A preparation method for a novel antibacterial and anti-radiation silver-impregnated fiber fabric, comprising the following steps:

[0038] (1) Immerse the fiber fabric in the antibacterial silver solution, the immersion temperature is 30°C, the immersion time is 30 minutes, the bath ratio is 1:5g / g, and then the fiber fabric is dried at 45°C;

[0039] (2) Immerse the fiber fabric in step (1) in the water-resistant finishing solution, the immersion temperature is 55°C, the immersion time is 30 minutes, the bath ratio is 1:3g / g, and then the fiber fabric is dried at 50°C to obtain New antibacterial anti-radiation silver impregnated fiber fabric.

[0040] The antibacterial silver solution comprises the following components by weight: 5 parts of silver antibacterial agent, 6 parts of cetyltrimethylammonium bromide, 2 parts of guar gum, 7 parts of sodium dodecylbenzenesulfonate , 1000 parts of water. The preparation method of the antibacterial silver solution is as follow...

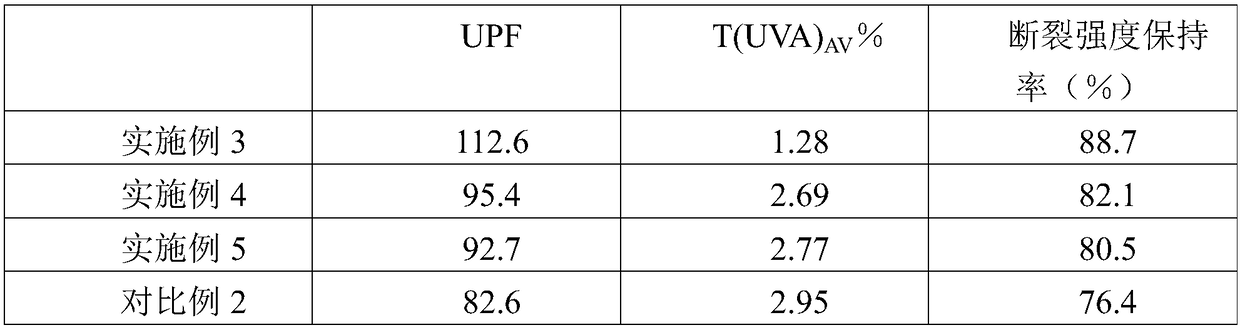

Embodiment 3

[0049] A preparation method for a novel antibacterial and anti-radiation silver-impregnated fiber fabric, comprising the following steps:

[0050] (1) Immerse the fiber fabric in the antibacterial silver solution, the immersion temperature is 30°C, the immersion time is 30 minutes, the bath ratio is 1:5g / g, and then the fiber fabric is dried at 45°C;

[0051] (2) Immerse the fiber fabric in step (1) in the water-resistant finishing solution, the immersion temperature is 55°C, the immersion time is 30 minutes, the bath ratio is 1:3g / g, and then the fiber fabric is dried at 50°C;

[0052] (3) Immerse the fabric in step (2) in the anti-radiation finishing solution, the immersion temperature is 35°C, the immersion time is 15 minutes, the bath ratio is 1:3g / g, and then the fiber fabric is dried at 50°C to obtain the new Antibacterial anti-radiation silver impregnated fiber fabric.

[0053] The antibacterial silver solution comprises the following components by weight: 5 parts of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com